Device for cleaning dust deposited in pipeline

A cleaning device and a technology for accumulating dust, which are applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of affecting airflow, blockage, cumbersome links, etc., so as to achieve convenient installation and disassembly, and easy installation and use. , The effect of convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

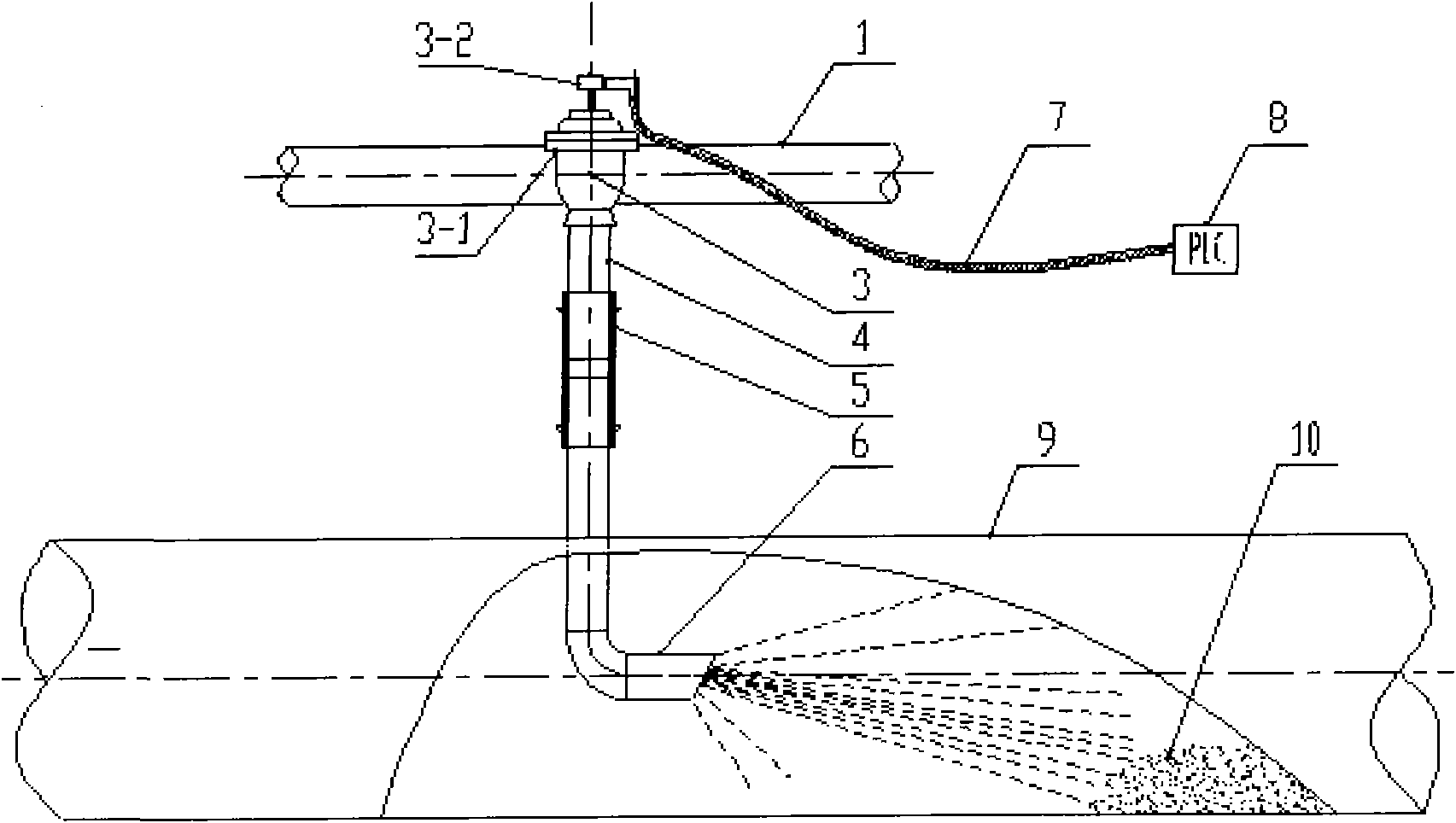

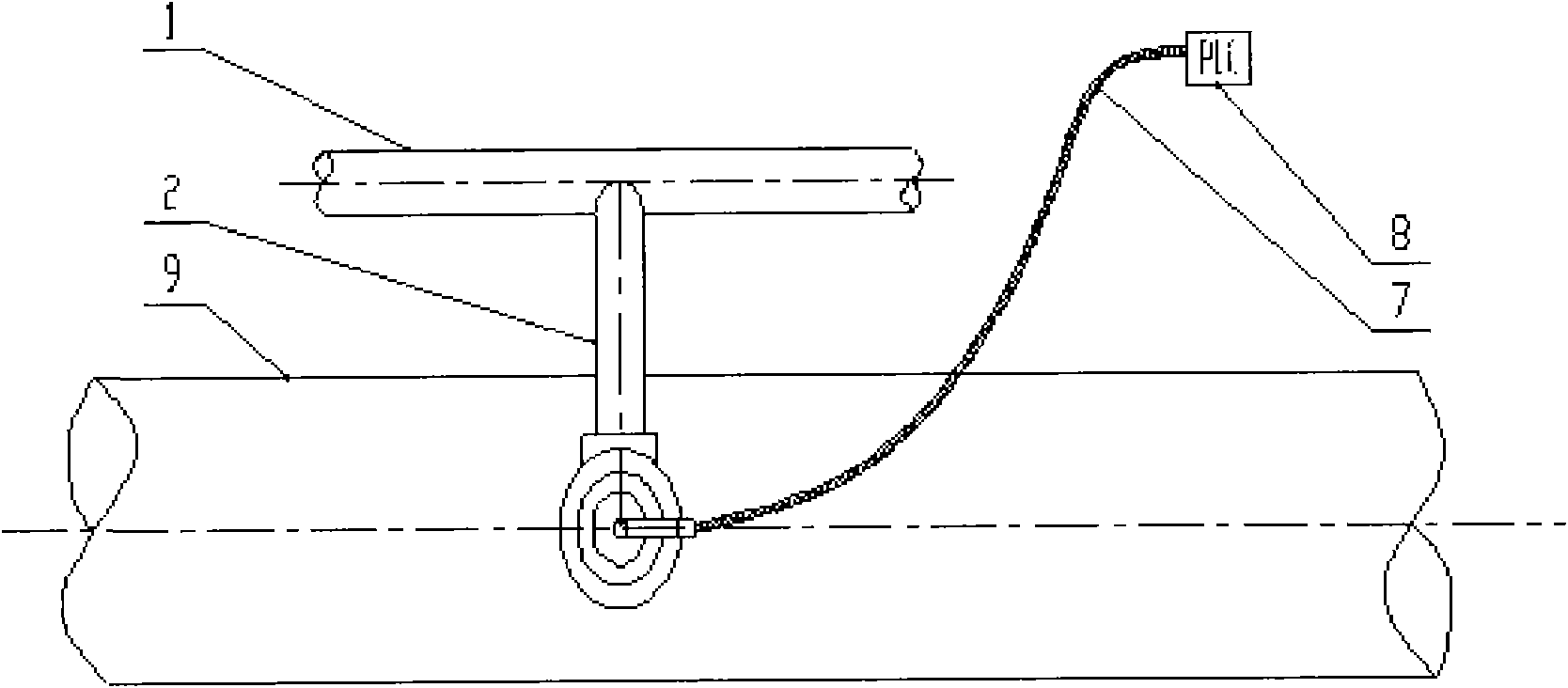

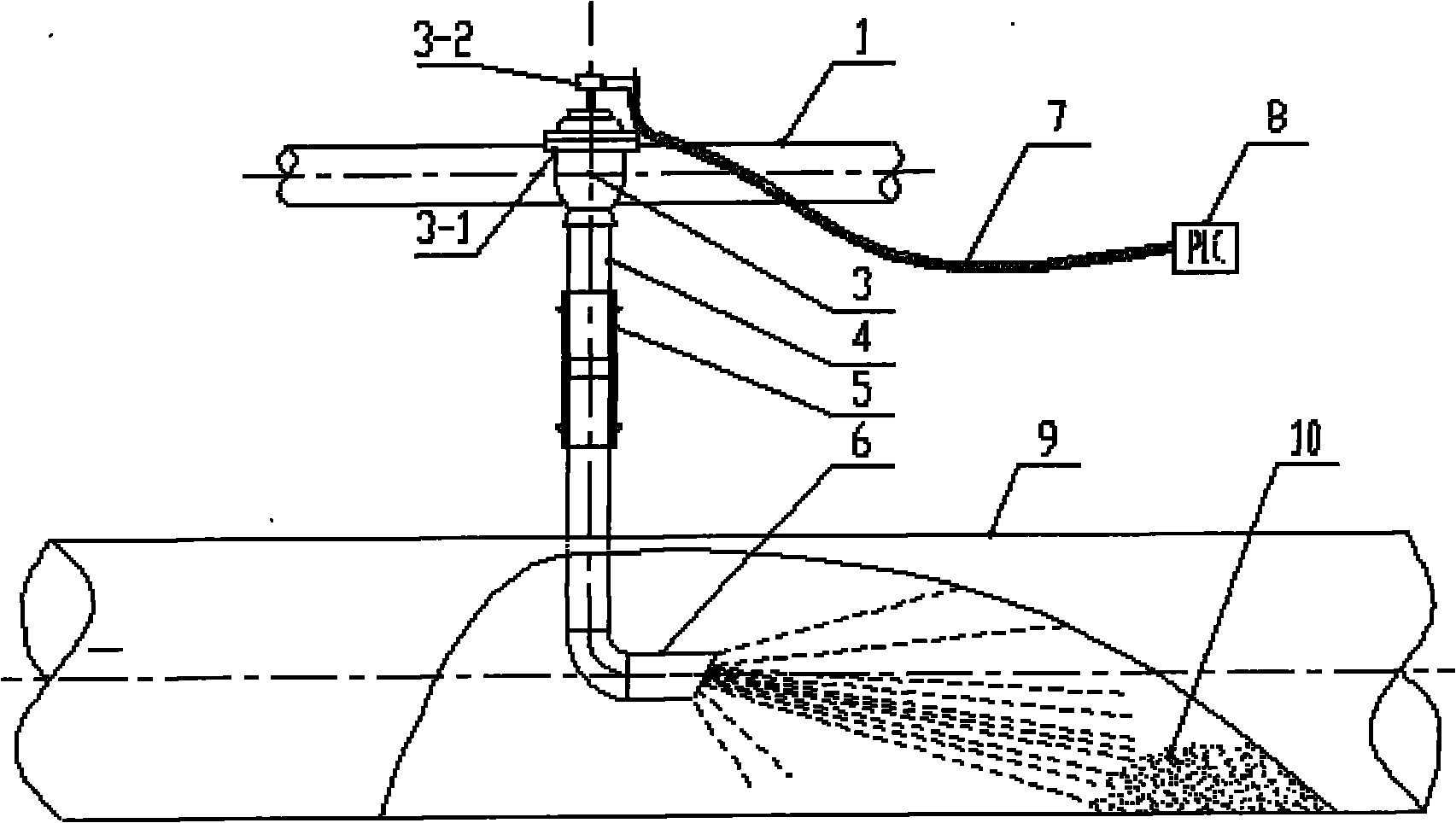

[0014] A pipeline dust cleaning device, including a plurality of blowing pipes 6 fixedly installed on the air flow pipe 9 with the dust 10, the blowing pipe 6 is composed of a straight pipe, a 90° elbow, and a nozzle with a cut angle. The end extends out of the airflow pipe and is connected to the blowing branch pipe 4 through a high-pressure hose 5 with a clamp. The other end of the blowing branch pipe 4 is connected to the pulse valve 3-1 of the electromagnetic pulse valve 3, and the pulse valve 3 -1 is also connected to the air supply branch pipe 2, and the solenoid valve 3-2 of the electromagnetic pulse valve 3 is connected to the controller 8 through the control cable 7; the center line of the nozzle of the blowing pipe 6 and the center line of the air flow pipe 9 coincide.

[0015] When dust 10 appears in the airflow pipe 9, the solenoid valve 32 on the electromagnetic pulse valve 3 can be activated by the controller 8, and the pulse valve 3-1 is opened, and compressed gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com