Stepless eccentricity adjustable rotating arc sensor

A technology of rotating arc and sensor, applied in the direction of electrode support device, welding rod characteristics, etc., can solve the problems of high mechanical vibration and noise, complicated assembly and disassembly, and easy burning of the contact tip, so as to reduce the difficulty of processing, reduce the cost and facilitate control. Effect

Inactive Publication Date: 2011-06-15

XIANGTAN UNIV

View PDF7 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to overcome the defects of inconvenient adjustment of the eccentricity of the existing rotating arc, easy burning of the contact tip, easy damage of the carbon brush, large mechanical vibration and noise, and complicated assembly and disassembly, the present invention aims to provide a rotating arc with stepless adjustable eccentricity. The sensor, which is driven by a motor to adjust the rotating scanning device of the rotating eccentric radius, can enhance the practicality of the rotating arc

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

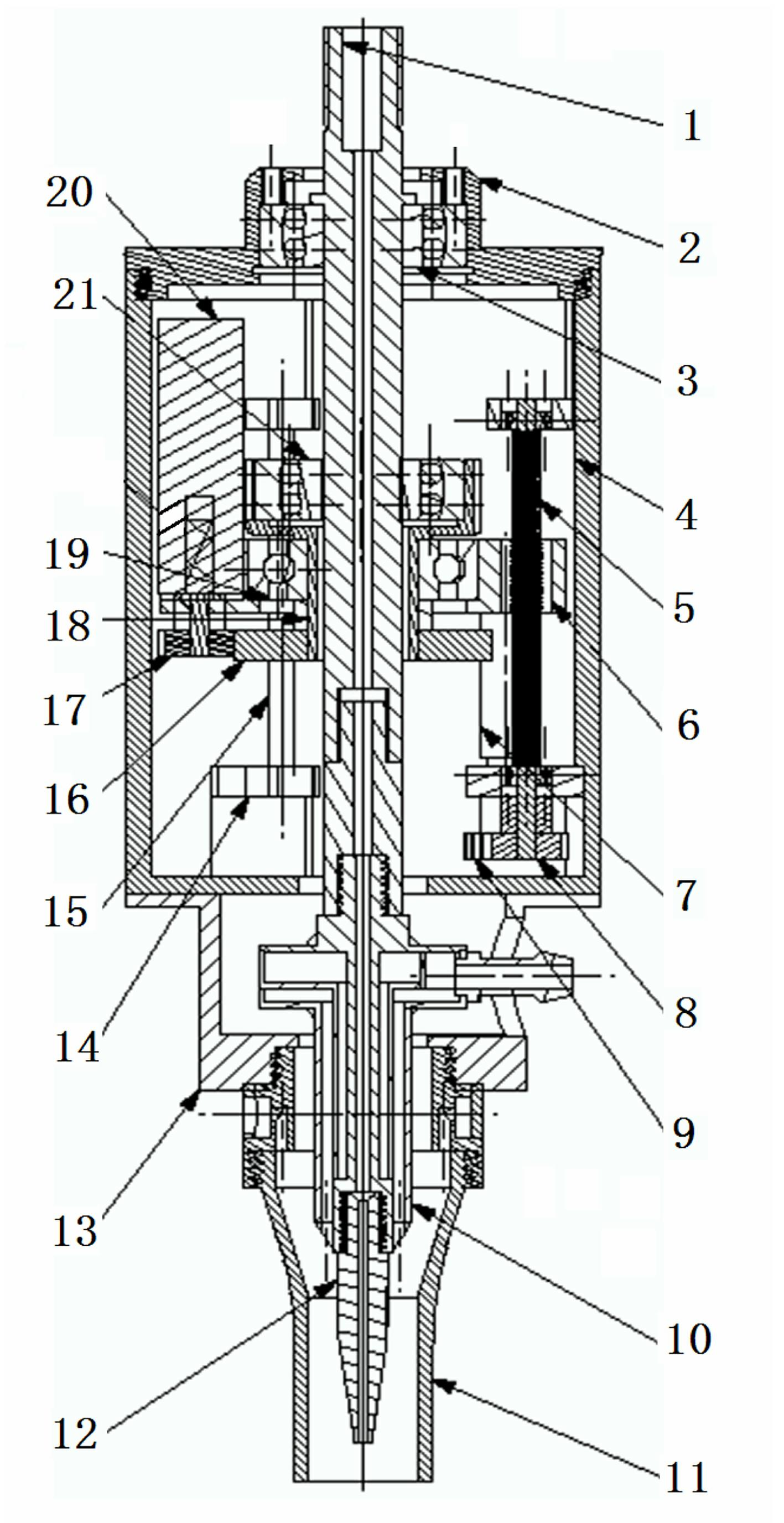

The invention discloses a stepless eccentricity adjustable rotating arc sensor, belongs to the field of welding auxiliary devices, and aims to solve the problems of inconvenient adjustment of eccentricity, large mechanical vibration and noise and the like of the conventional rotating arc sensor. The sensor comprises a shell and a conducting rod; an eccentricity adjusting platform is arranged in the shell, and is provided with an eccentricity adjusting motor and a ball screw; a rotary platform driven by a micromotor through a gear is arranged in the eccentricity adjusting platform; a hinge is formed between the upper end of the conducting rod and the top of the shell; the conducting rod passes through an eccentric rotor and is in hinge connection with a self aligning ball bearing; the lower end of the conducting rod is fixedly connected with a vapor protective joint of which the lower end is provided with a conducting nozzle; and a welding wire passes through the conducting rod to rotate, and can form a conducting tight movable fit with the conducting nozzle. The sensor can precisely generate rotating welding arcs with different turning radii, realizes stepless adjustment of eccentric radii, is simple in structure and stable in performance, and is a brand-new concept rotating arc sensor.

Description

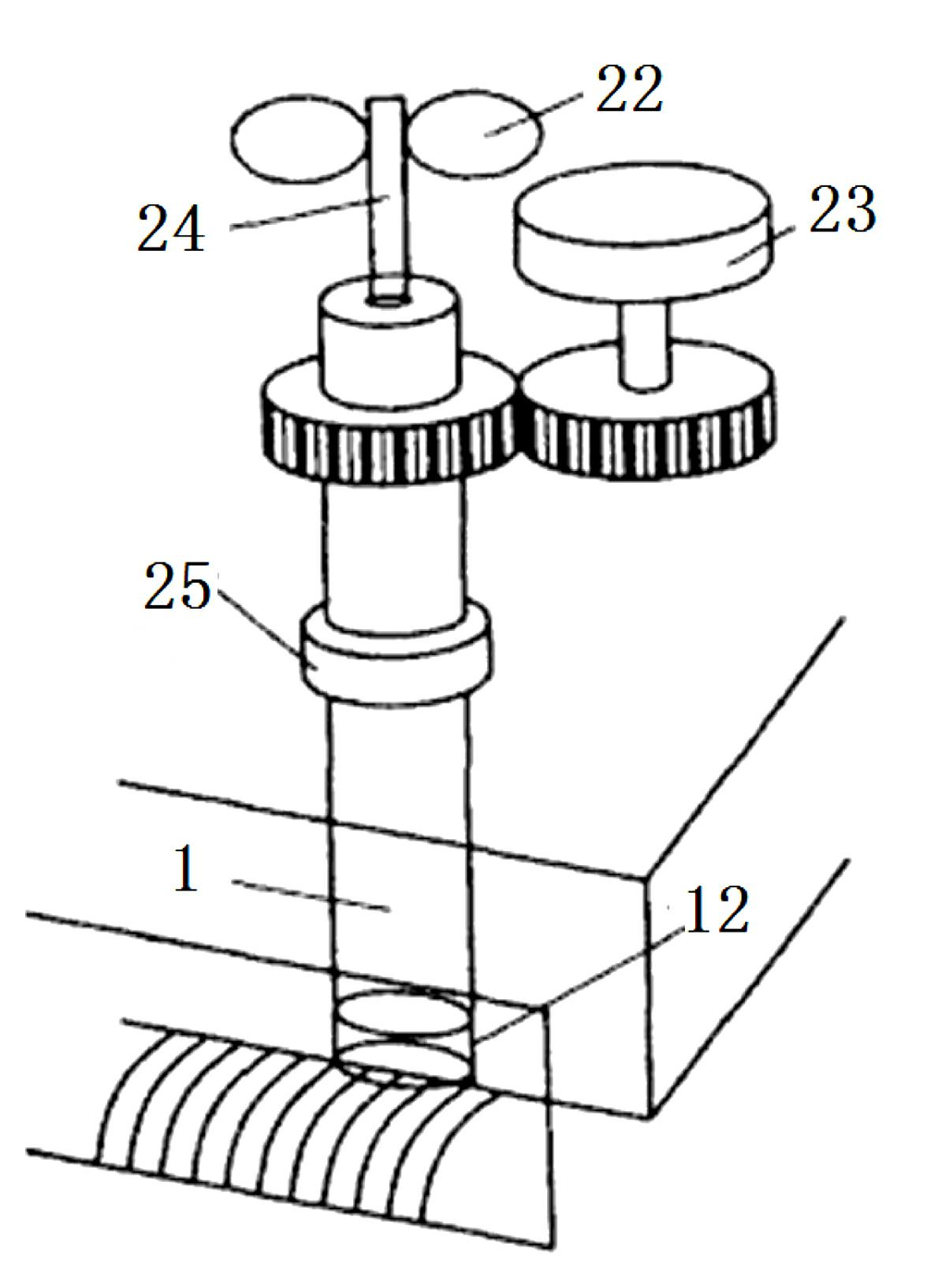

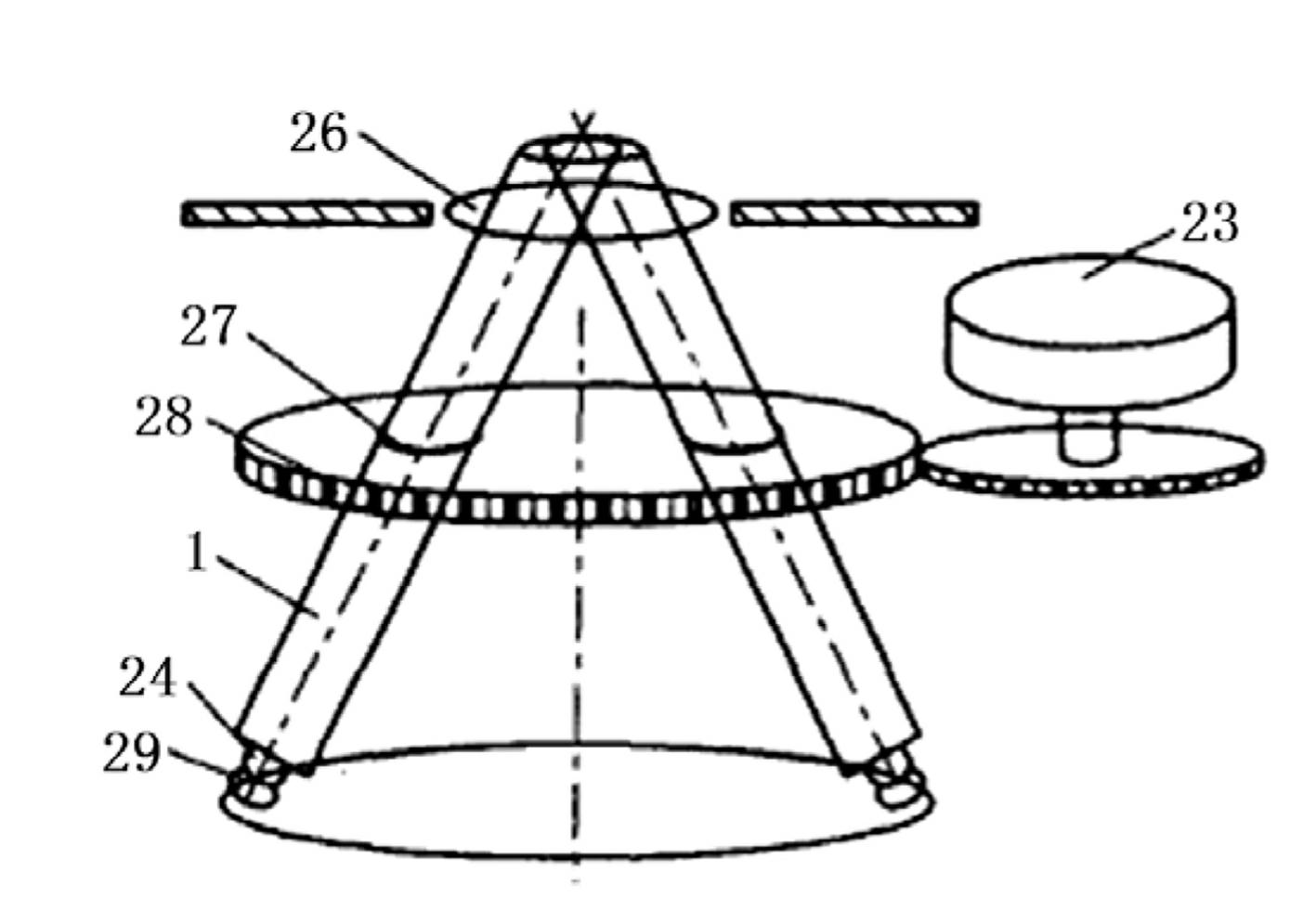

Rotating arc sensor with infinitely adjustable eccentricity technical field The invention relates to a welding auxiliary device, in particular to a rotating arc sensor device whose rotation eccentric radius is adjusted by a motor. Background technique Rotate the arc sensor device to make the welding arc swing in the direction perpendicular to the welding process, and the welding torch itself or the conductive rod in the welding torch make a horizontal scanning movement. The main representative mechanisms are: one was invented by NKK Corporation of Japan in the 1980s Conductive rod cylindrical rotation mode, its structure as shown in Figure 2. It relies on the eccentricity of the lead-out hole of the welding wire 24 on the end surface of the conductive rod 1 to realize the arc rotation movement, and the eccentricity of the lead-out hole is the arc rotation radius. The other is the conical rotation mode of the conductive rod developed by the German Aachen company. As shown ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K9/28

Inventor 洪波李湘文洪宇翔尹力屈岳波

Owner XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com