Three-decker railway freight car with detachable top decker

A technology for railway wagons and car bodies, which is applied in the field of top-layer foldable three-story railway wagons, which can solve problems such as waste of transport capacity, and achieve the effect of reducing waste of transport capacity and increasing transport capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

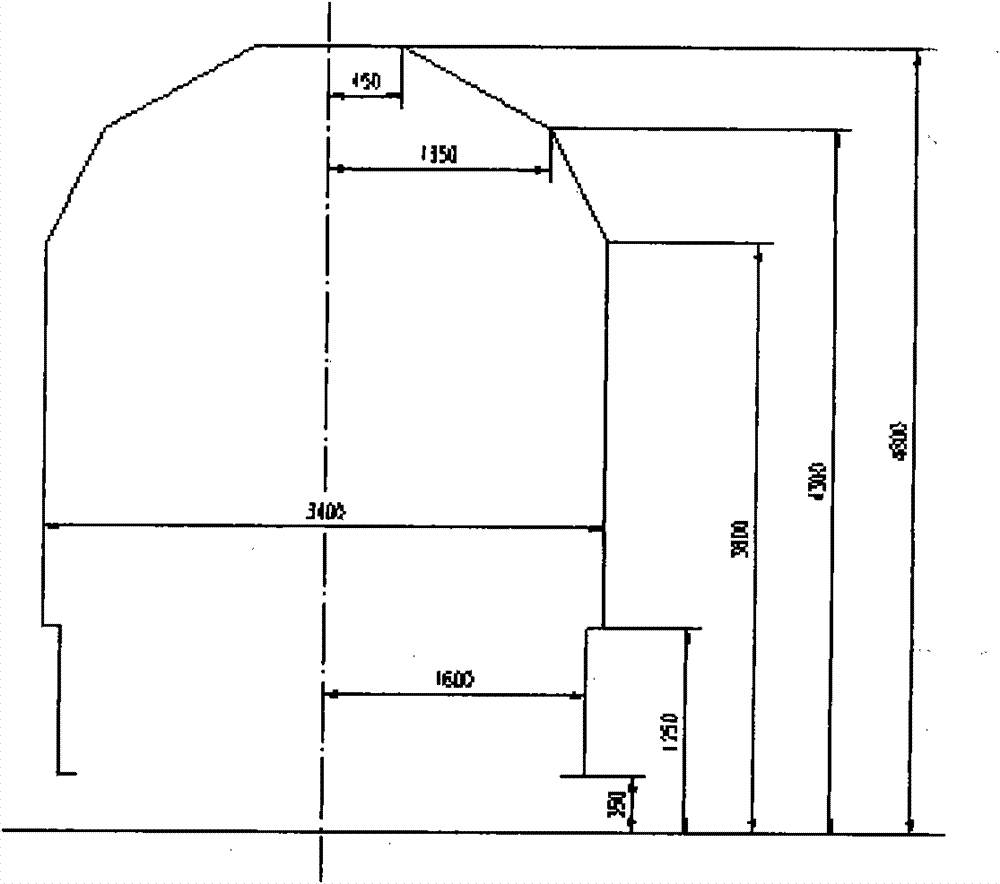

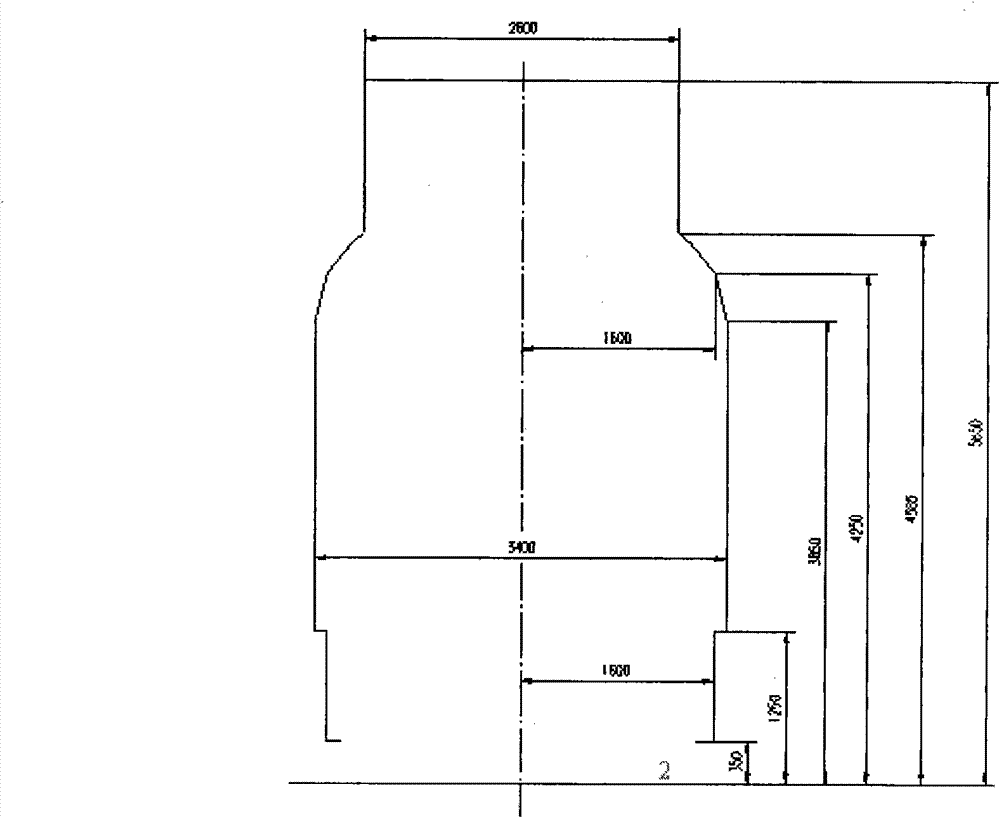

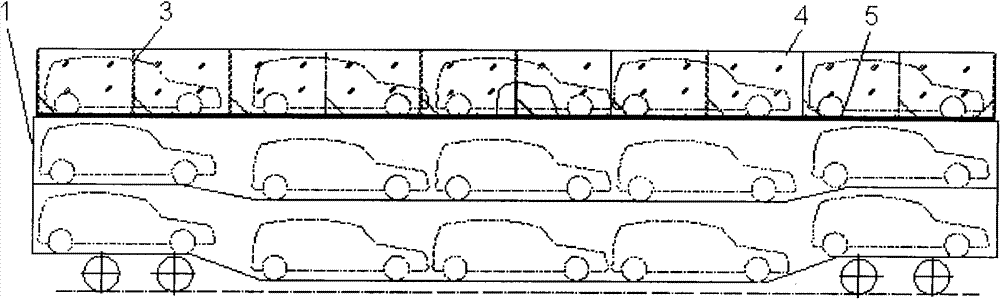

[0015] Such as image 3 , Figure 4 As shown, the present invention includes a general double-decker car body 1, and the total height of the car body 1 is not more than 4.8 meters. On the second floor roof of the car body 1, lay a floor 2 punched with several rows of automobile binding with flanged oblong holes, and between the floor 2 and the second floor roof, there is a hanging space for the hook of the automobile reinforcement binding device. At the same time, a guard rail 3 that can be folded longitudinally along the vehicle is set on the second floor roof of the car body 1, and the total height of the car body 1 is not more than 5.85 meters when the guard rail 3 is erected. The outer covering sheet 4 of the protective fence 3 covers and protects the loaded vehicle. The two sides of the sheet 4 are fixed on the protective fence 3 through the bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com