Positioning device for butting wing body

A positioning device and wing body technology, which is applied to ground devices, aircraft assembly, transportation and packaging, etc., can solve the problems of high measurement and synchronization requirements, damaged systems, and many motors, so as to simplify the system complexity and ensure safety and reliability Sexuality and cost reduction effect

Active Publication Date: 2011-06-15

COMAC +1

View PDF7 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this positioning method also has many disadvantages.

First of all, such a positioning method will make the structure of the positioning system complex

Secondly, more motors are required, higher requirements are placed on the performance of the control system, and higher requirements are placed on the measurement and synchronization of the movement of each axis, all of which increase the cost of the positioning system

In addition, the more controlled degrees of freedom, the more processes that need motion decoupling, which not only increases the complexity of the leveling algorithm, but also increases the problem of destroying the system due to over-constraint caused by algorithm instability or hardware failure

Finally, the existing positioning methods have very high requirements for manufacturing installation, measurement and foundation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

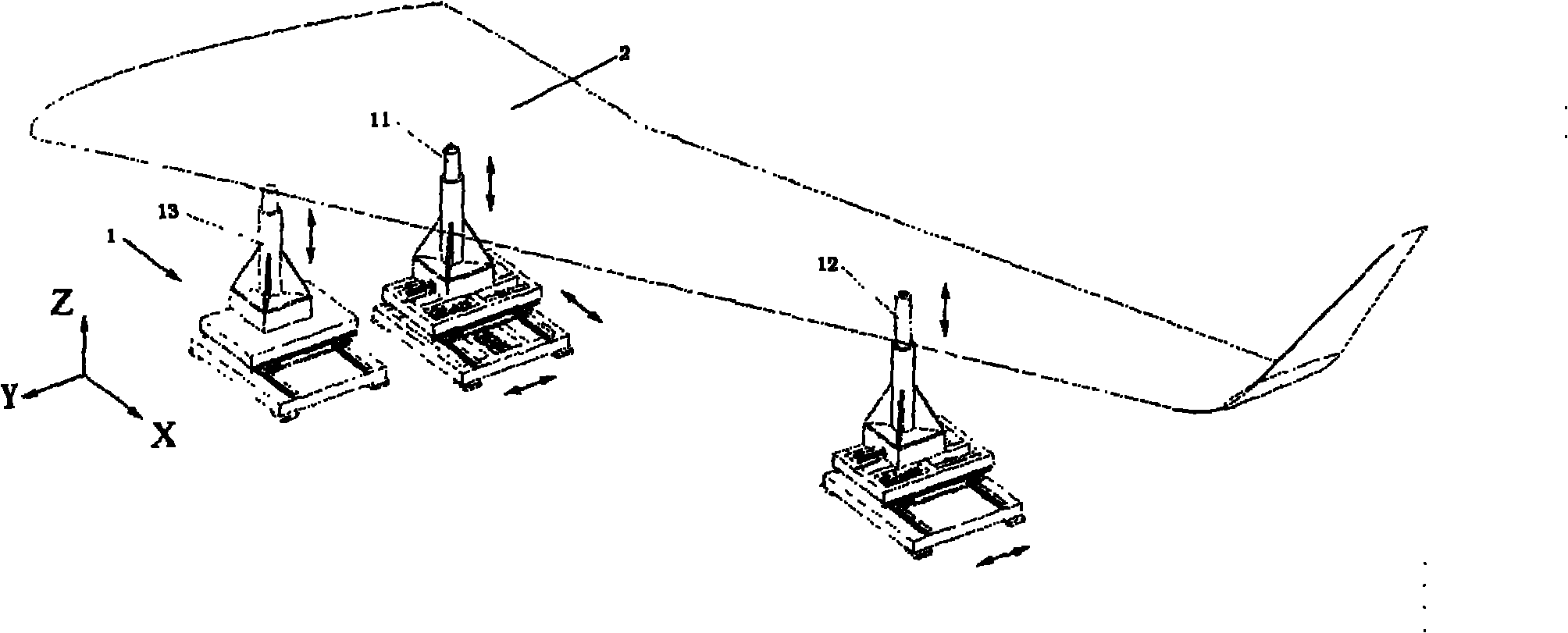

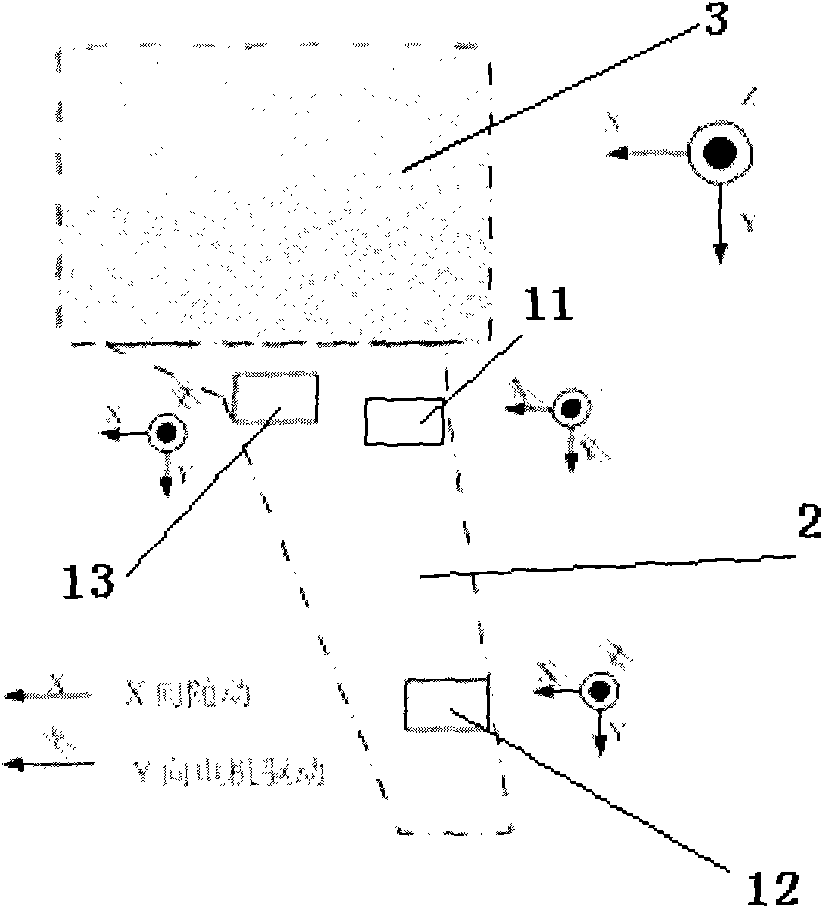

The invention relates to a positioning device for butting a wing body, which is characterized in that the positioning device comprises three positioners for performing attitude adjustment on a part of an airplane, wherein the first positioner is placed at a support point with maximum bearing pressure on a wing and can do translation motion freely in X, Y and Z directions; the second positioner is placed at a farthest point in the X direction of the wing and can do the translation motion freely in the Y and the Z directions and do driven movement in the X direction; and the third positioner is determined according to the position of gravity center of the part of the airplane, the position of the third positioner needs to enable a connecting part for the part of the airplane to meet strength requirement, and enable the stress on each positioner to be uniform, and the third positioner can do the translation motion freely in the Z direction and do the driven movement in the X and the Y directions. The positioning system does not need multi-axis linkage, thereby simplifying the complexity of the system, simultaneously ensuring the safety and the reliability, reducing the cost, reducing the cost for manufacturing, mounting and measuring, and also reducing the cost of a foundation.

Description

Positioning device for wing body docking technical field The invention relates to the field of aircraft reinstallation, in particular, the invention relates to a positioning system and a positioning method for aircraft installation. Background technique The butt joint assembly of aircraft wing and body is a complex and time-consuming assembly process, and the quality directly affects the flight safety of the aircraft. The traditional assembly process uses a large number of fixed tooling and scaffolding, the assembly cycle is long, the labor intensity of the workers is high, and the assembly quality is low and unstable. In the past ten years, new large aircraft represented by Boeing 777, 787, A340, and A380 have concentratedly reflected the embodiment and development trend of advanced aircraft assembly technology, and one of their characteristics is the extensive use of digital automatic docking systems. The above-mentioned digital automatic docking system is mainly comp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B64F5/00

CPCB64F5/0009B64F5/10

Inventor 陈磊方伟邢宏文翁进良王莉

Owner COMAC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com