BaO-Ln2O3-TiO2-series microwave capacitor medium material and preparation method thereof

A technology of bao-ln2o3-tio2 and capacitor dielectric, which is applied in the direction of fixed capacitor dielectric, fixed capacitor parts, ceramics, etc., can solve the problems of large temperature coefficient and no main component, and achieve excellent microwave dielectric properties and excellent microwave Dielectric properties, the effect of satisfying mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention will be further described, but the content of the present invention is not limited to embodiment.

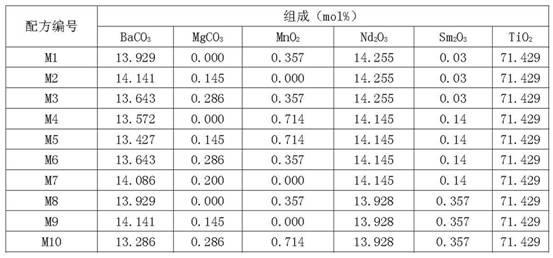

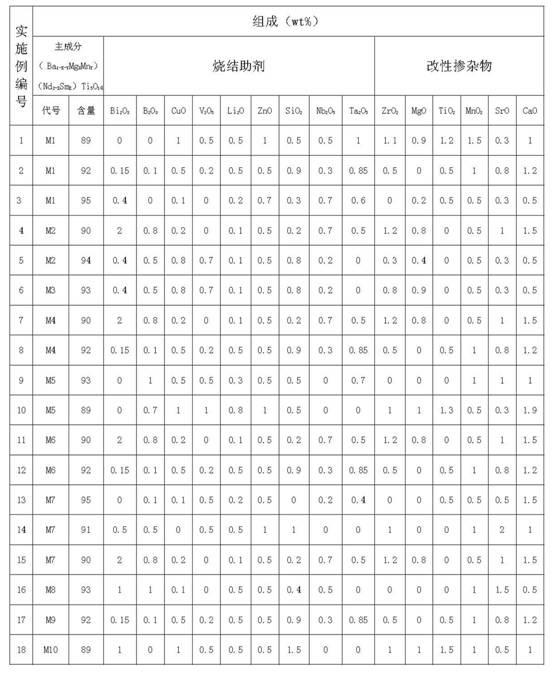

[0015] The microwave capacitor dielectric material provided by the present invention is composed of: main component (Ba 1-X-Y Mg X mn Y ) (Nd 2-Z SM Z ) Ti 5 o 14 The solid solution is 89-96wt%, the sintering accelerator is 1.5-5wt%, and the modified dopant is 0.5-6wt%.

[0016] In the above composition, the main component is prepared by solid phase method at 1200℃~1300℃ (Ba 1-X-Y Mg X mn Y ) (Nd 2-Z SM Z ) Ti 5 o 14 , where X=0~0.02, Y=0~0.05, Z=0.002~0.025; sintering aids include Bi 2 03 , B 2 0 3 , CuO, V 2 0 5 , Li 2 O, ZnO, SiO 2 , Nb 2 o 5 、 Ta 2 o 5 One or more mixtures of oxides with low melting points; modified dopants include different metal oxides such as ZrO 2 , MgO, TiO 2 , MnO 2 , SrO and CaO etc. one or more mixtures.

[0017] The weight percentage of the above-mentioned s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com