High fatigue resistance glass fiber reinforced nylon material and preparation method thereof

A glass fiber, fatigue-resistant technology, applied in the field of polymer materials, can solve the problems of not mentioning the fatigue resistance of materials, the degree of fatigue resistance of materials, and the lack of description of fatigue resistance, so as to achieve mature production technology, The effect of high fatigue resistance and high mechanical properties

Inactive Publication Date: 2011-06-15

SHANGHAI KINGFA SCI & TECH +1

View PDF6 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The published patent CN1854287 mentions the research on the modification of engineering plastics (PA), but it does not explain the fatigue resistance of the material to what extent

Both patents CN1508358A and CN101412845A mentioned glass fiber reinforced nylon material, but did not mention material fatigue resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

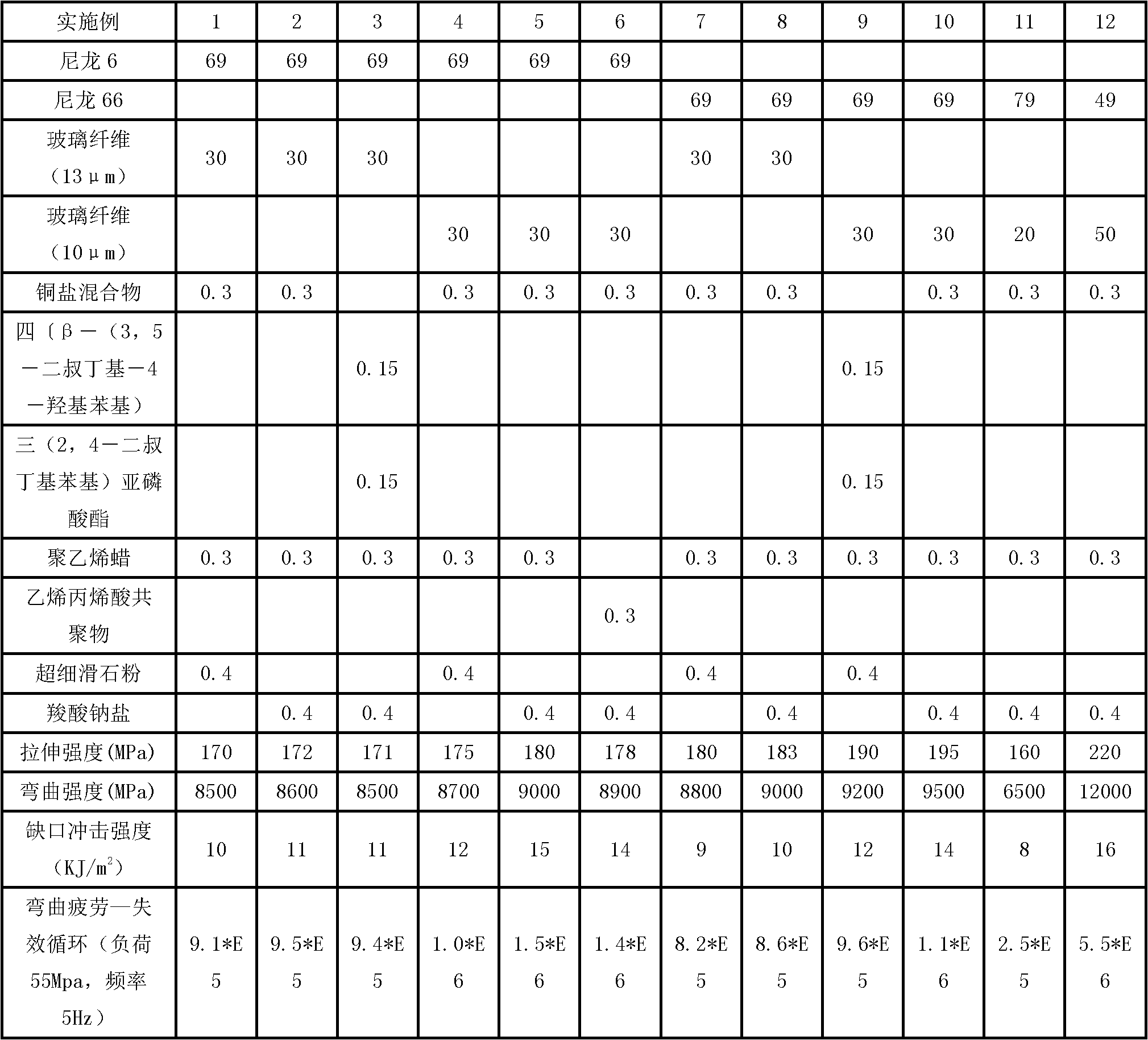

The invention relates to a high fatigue resistance glass fiber reinforced nylon material and a preparation method thereof. The fatigue-resistance glass fiber reinforced nylon material comprises the following raw materials in percentage by weight: 48.2 to 79.7 percent of nylon resin, 20 to 50 percent of glass fiber, 0.1 to 0.6 percent of antioxygen, 0.1 to 0.6 percent of lubricant, 0.1 to 0.6 percent of nucleating agent. The high fatigue resistance glass fiber reinforced nylon material is prepared by melting and blending the components at 210 to 300 DEG C. The glass fiber reinforced nylon material prepared by the method has high fatigue-resistance performance as well as high mechanical performance and high surface performance. The production process is mature. The glass fiber reinforced nylon material can be widely used for making parts around automotive motors and parts in other industries.

Description

A kind of high fatigue resistance glass fiber reinforced nylon material and preparation method thereof technical field The invention relates to a glass fiber reinforced nylon material with high fatigue resistance and a preparation method thereof, which can be applied to the automobile industry and various industries requiring high fatigue resistance glass fiber reinforced nylon, and belongs to the technical field of polymer materials. Specifically, the nylon material is preferentially used in components that require high fatigue resistance, especially peripheral parts of automobile engines, such as intake manifolds, engine covers, valve chamber covers, and air filters. Background technique Nylon resin has excellent comprehensive properties such as high mechanical strength, heat resistance, self-lubricating property, excellent barrier performance and chemical corrosion resistance. It is widely used in machinery manufacturing, electronic appliances and transportation and othe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L77/00C08L77/02C08L77/06C08K13/04C08K7/14B29B9/06B29C47/92B29C48/92

CPCC08K5/0008C08L77/00C08J5/043C08J2377/02B29C48/04B29C48/40B29C48/92B29C2948/92704B29C2948/92895B29C2948/92923

Inventor 冯德才丁正亚孙雅杰梁惠强

Owner SHANGHAI KINGFA SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com