Oppositely arranged swing piston type vacuum pump used for automobiles

A technology of vacuum pump and piston type, which is applied in variable capacity pump components, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of high noise and short continuous working time, and achieve high output power and continuous The effect of long working hours and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

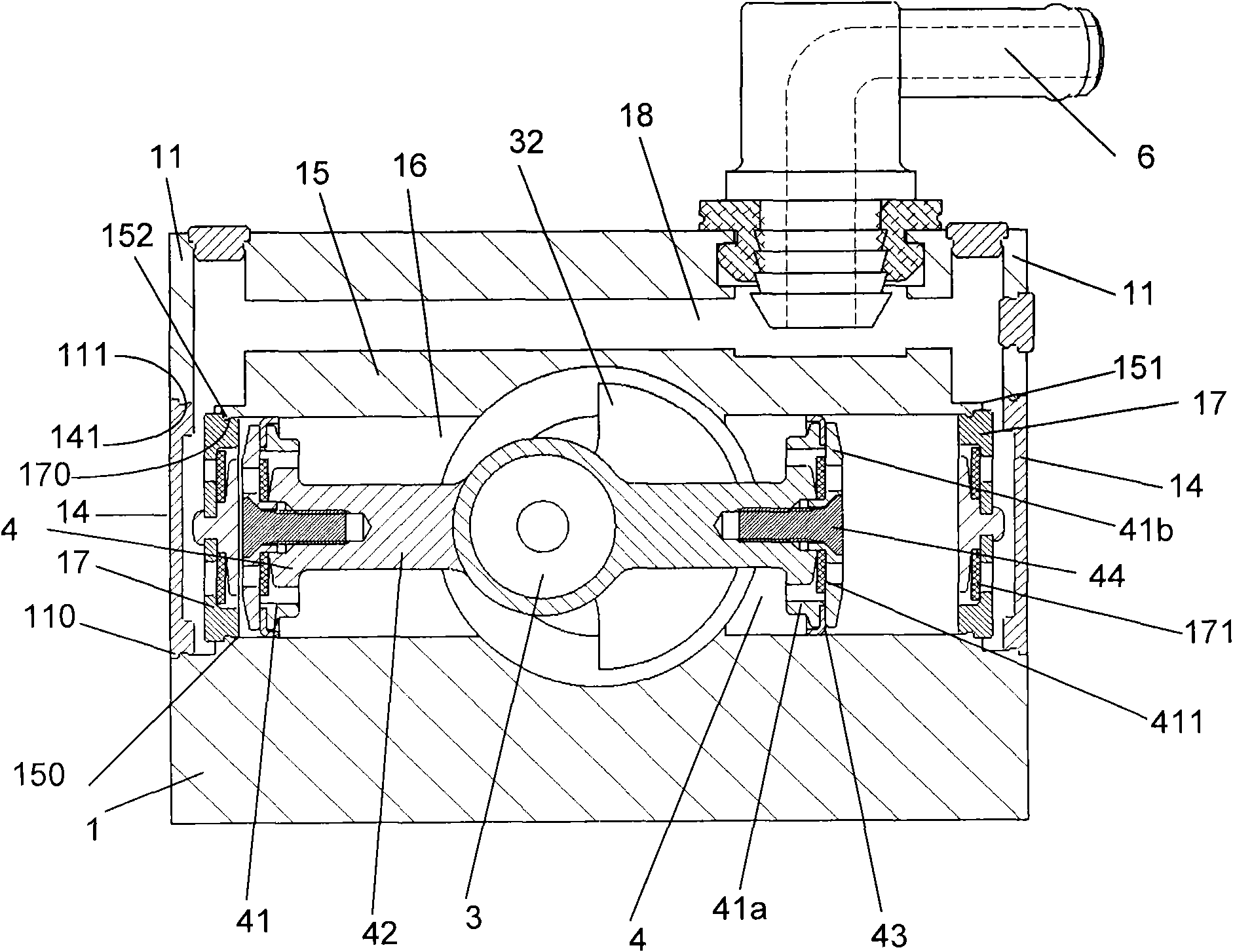

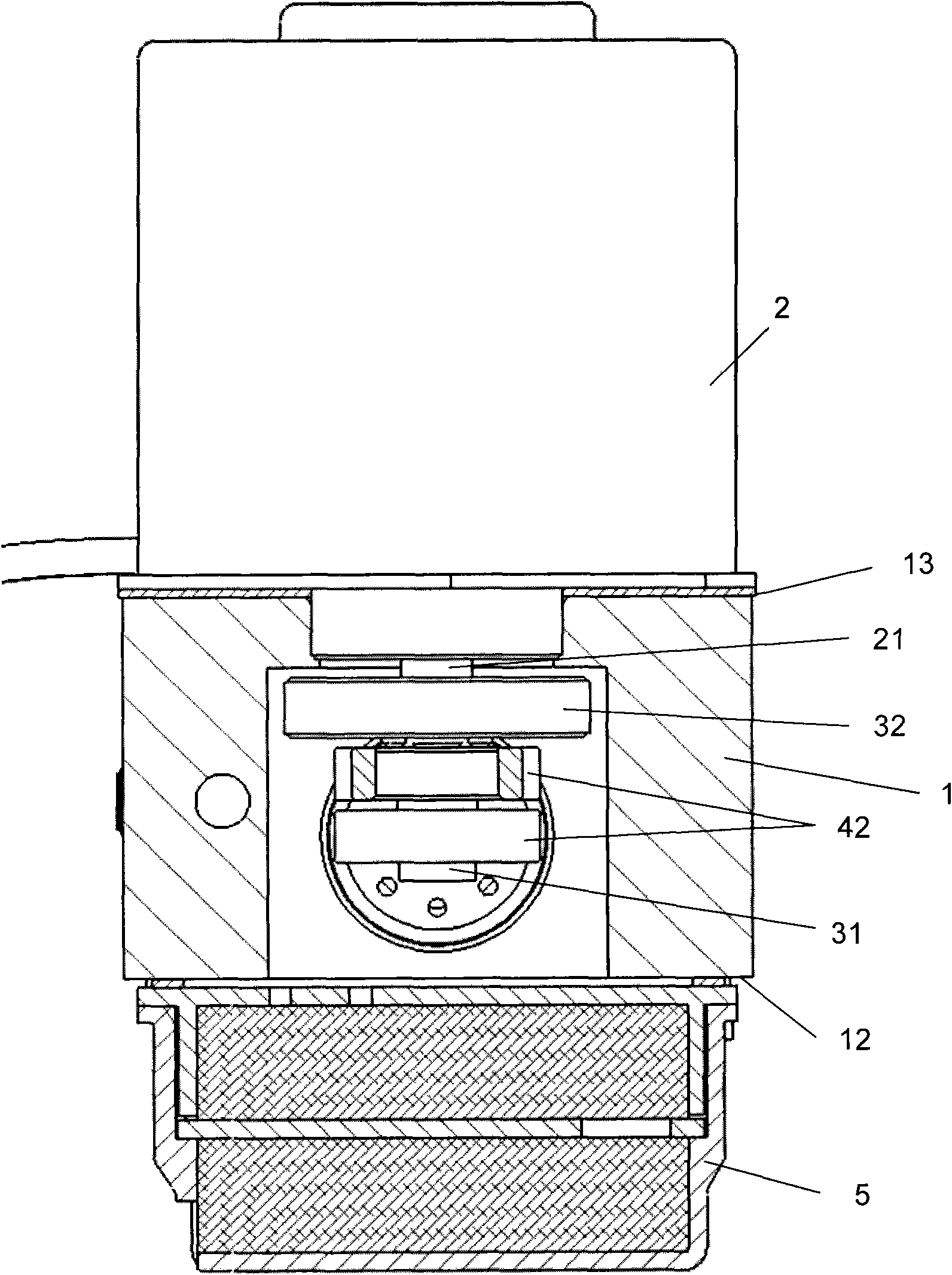

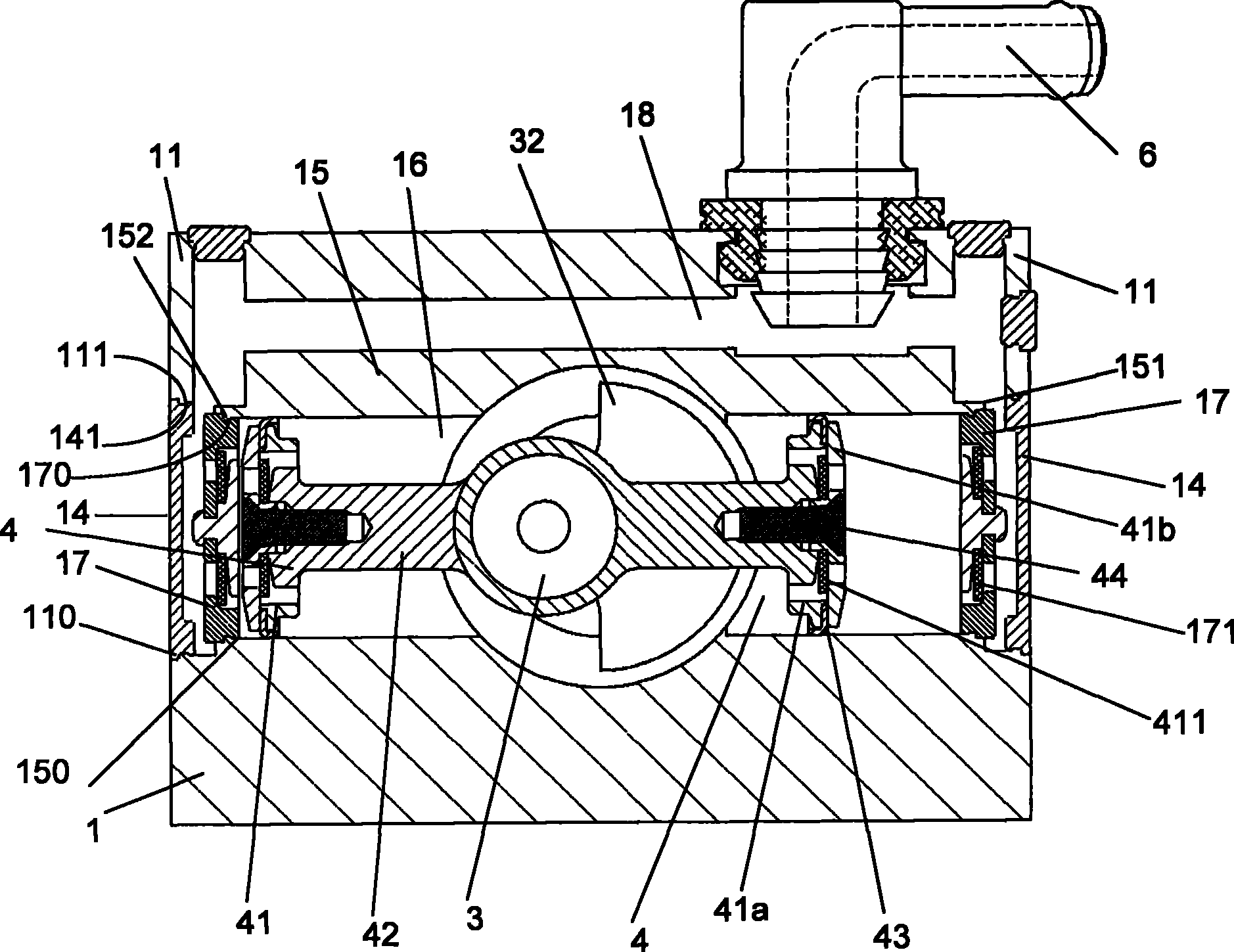

[0009] refer to figure 1 and figure 2 , The opposed rocking piston vacuum pump of the present invention includes a pump body 1 , a power source 2 , an eccentric shaft 3 and a pair of pistons 4 .

[0010] The pump body 1 includes two opposite outer end surfaces 11 , and a first through hole 110 is respectively defined on the two outer end surfaces 11 , and an outer end cover 14 sealing the first through hole is provided in each first through hole 110 . A cylinder 15 is also formed inside the pump body 1 , and the cylinder 15 defines a chamber 16 . The cylinder body 15 includes two inner end faces 151 respectively arranged relative to the two outer end faces 11, and a second through hole 150 is respectively opened on the two inner end faces 151, and each second through hole 150 is provided with a sealing second through hole 150. The inner end cap 17 of the through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com