Method for improving color rendering index and color temperature of low-color-temperature cold white light emitting diode (LED) matrix light source

A color rendering index, cool white light technology, applied in the field of LED semiconductor solid-state lighting, can solve the problems of loss of photoelectric conversion efficiency, low color rendering index, etc., to achieve the effect of improving the comfort of ambient lighting and improving the color rendering index

Inactive Publication Date: 2011-06-15

西安明泰半导体科技有限公司

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the low color temperature cool white LED has extremely high luminous efficiency, the color rendering index (CRI) is very low, Ra≤70, while the warm white light has a good color rendering index, Ra≥80, but it will lose more than 20% of the photoelectricity. Conversion efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

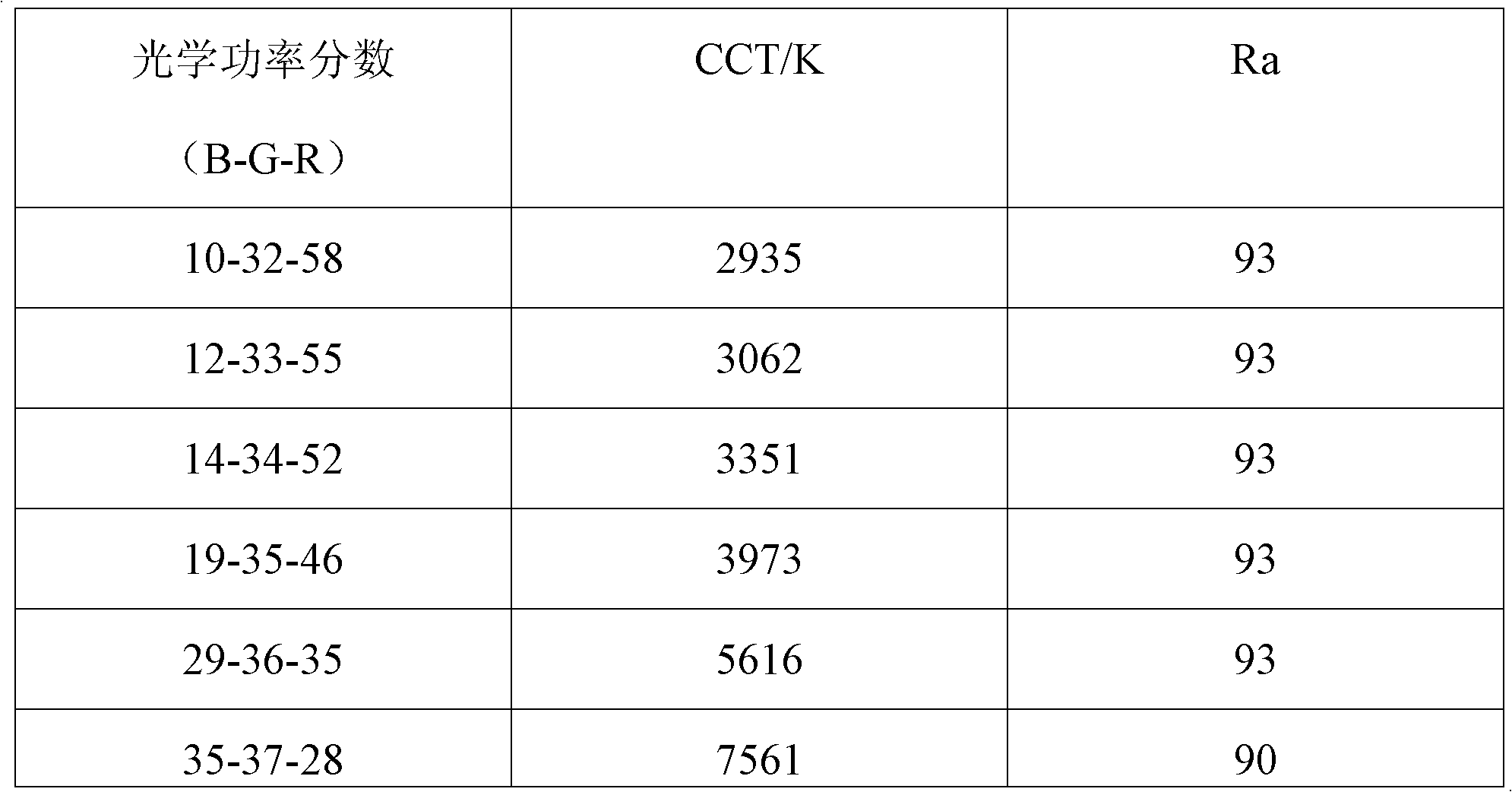

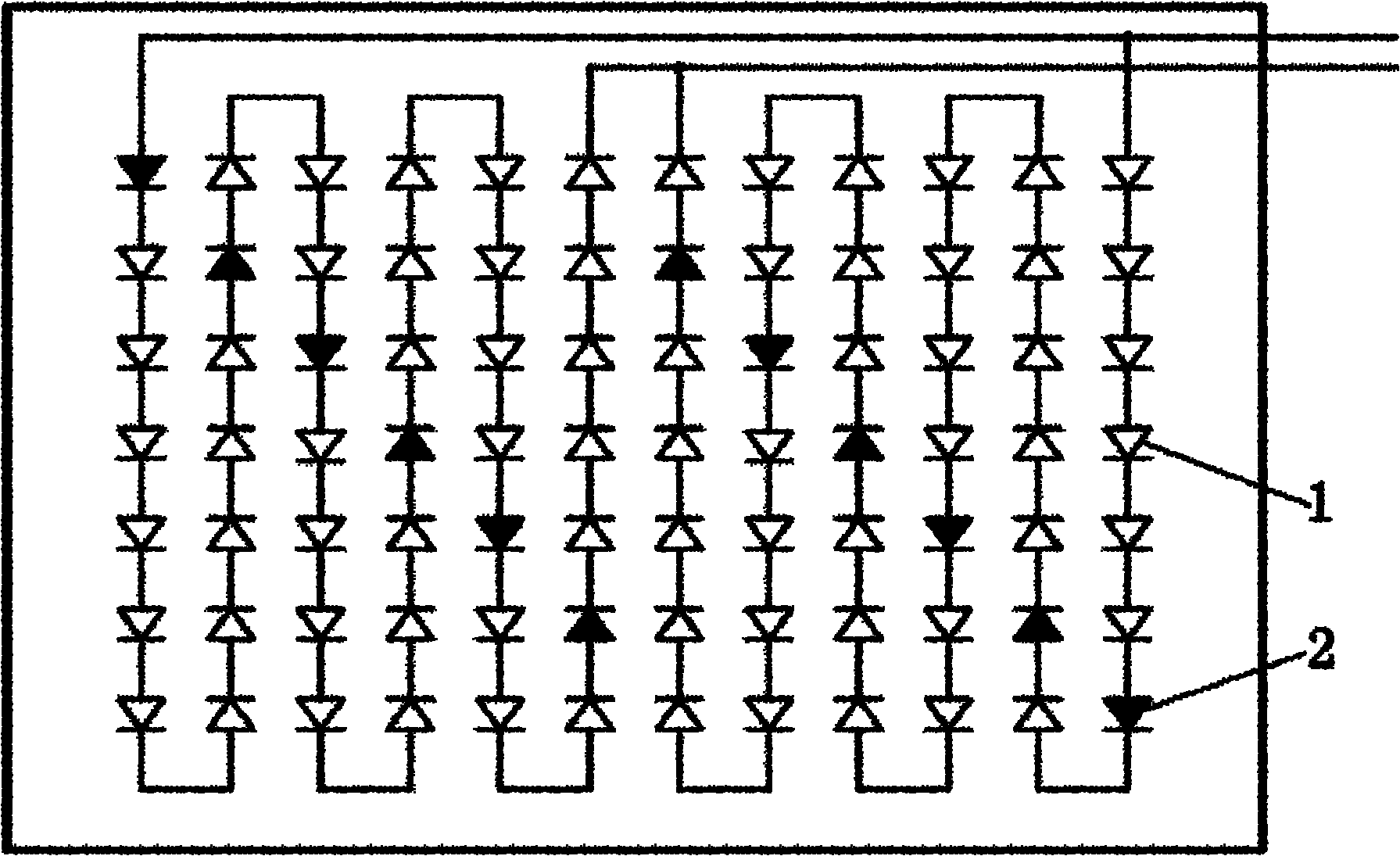

The invention discloses a method for improving color rendering index and color temperature of a low-color-temperature cold white light emitting diode (LED) matrix light source. Red LEDs are matched in a cold white LED matrix light source for compensation; and the number of the matched red LEDs is 0 to 15 percent of the total number of the LEDs; or green LEDs in an amount which is 0 to 5 percent based on the total number of the LEDs are matched in an assisting mode. In the method, the LED matrix light source plays a role in high lighting effect of a low-color-temperature cold white LED in application, the overall color rendering index of the matrix is improved, the color temperature of the light source is adjusted, energy conservation, low carbon and emission reduction are achieved, a better environmental lighting and color rendering effect is achieved, and the environmental lighting comfort degree is improved.

Description

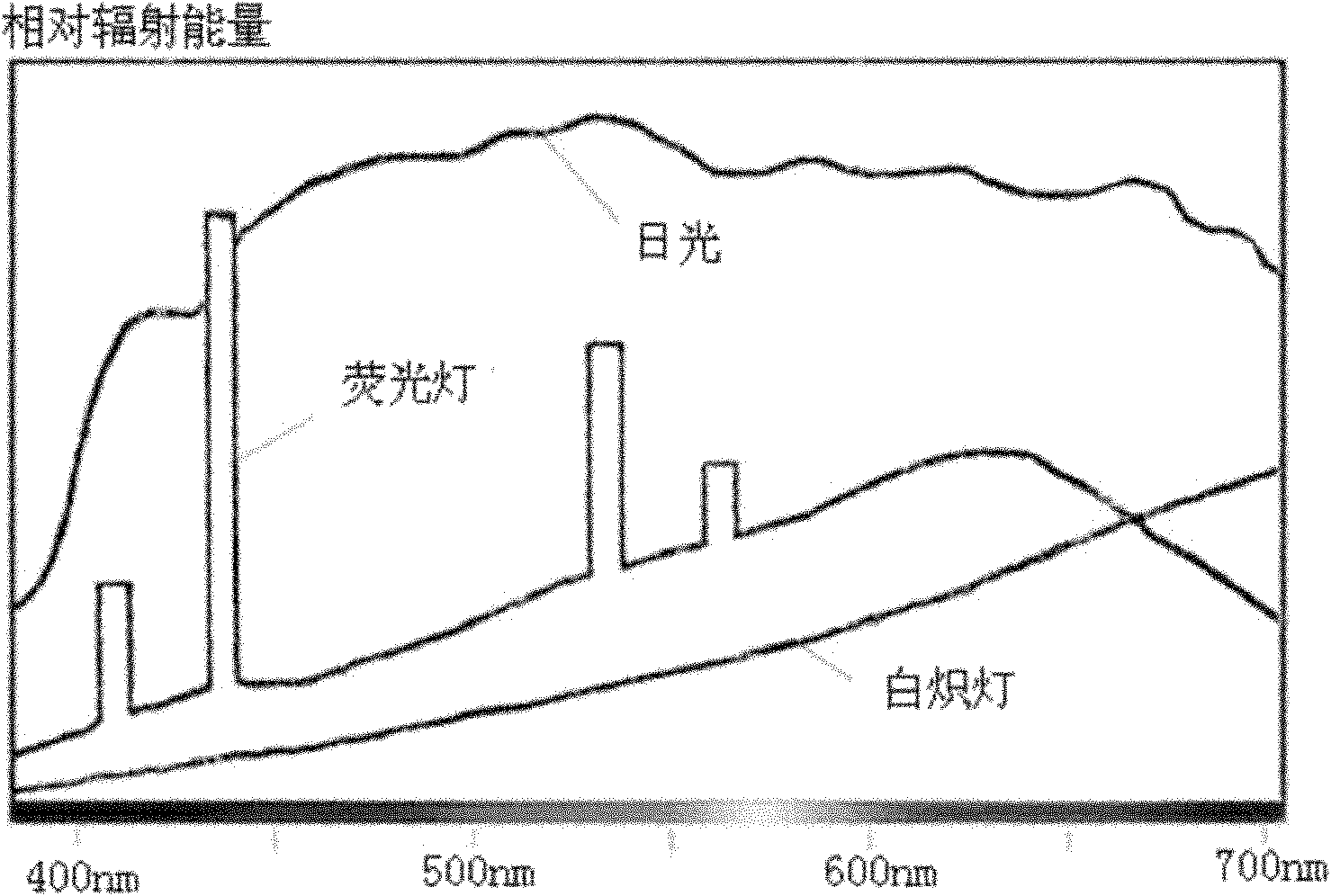

Method for Improving Color Rendering Index and Color Temperature of Low Color Temperature Cool White LED Matrix Light Source technical field The invention belongs to the technical field of LED semiconductor solid lighting, and relates to a method for improving the color rendering index and color temperature of a low color temperature cool white LED matrix light source. Background technique As we all know, low color temperature (5000K-10000K) cool white high-power LEDs have higher luminous efficiency. At present, commercial 1W LEDs have achieved a luminous efficacy of 130lm / W, and 1W medium white LEDs have a color temperature of 3700K-5000K. It can only achieve below 100lm / W, while the so-called high color rendering index warm white LWD with Ra≥80, color temperature CCT2600K-3700K, and 1W luminous efficacy can only achieve about 80lm / W. Higher luminous efficiency means more energy saving, and at the same time, the LED lamps produced have less heat generation, higher reliabi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F21V23/00F21V19/00

Inventor 邢先锋刘义芳王清平贾彧婕

Owner 西安明泰半导体科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com