Drier vibrator

A vibrating device and drying machine technology, which is applied in the direction of drying solid materials, drying, lighting and heating equipment, etc., can solve the problems of reduced work efficiency, long drying time, and materials are not easy to break, so as to improve work efficiency and have obvious effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

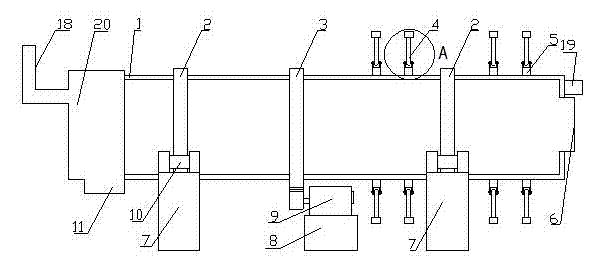

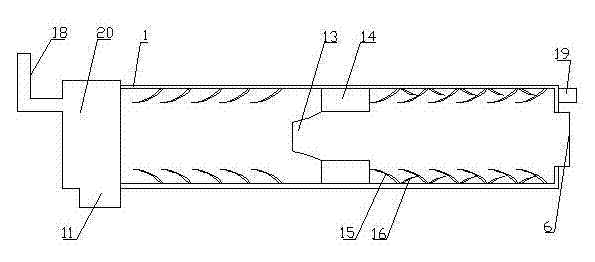

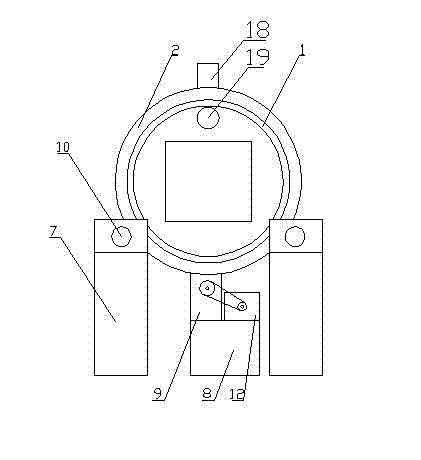

[0022] Embodiment 1: as figure 1 , 2 , 3, 4, and 5, a dryer vibration device includes a drum 1, a fixed sleeve 20 with an air inlet 18 and a discharge port 11 arranged on one side of the drum 1, and a fixed sleeve 20 arranged on the other side of the drum 1 The air outlet 19 and the feed port 6, the transmission gear 3 arranged on the outer wall of the drum 1, the reducer 9 connected with the transmission gear 3 through the gear, the motor 12 connected with the reducer 9 through the pulley, and the transmission gear 3 arranged on the The sliding wheel 2 on the outer wall of the drum 1 on both sides is matched with the roller shaft 10. It is characterized in that a vibrating hammer 4 is movably installed on the outer wall of the drum 1 through a support frame 5, and a filter bucket is arranged in the middle of the inner wall of the drum 1. 13. The inner wall of the drum 1 on both sides of the filter bucket 13 is provided with a forward flight board 15, and the reverse flight b...

Embodiment 2

[0024] Embodiment 2: as figure 1 , 2 , 3, 4, and 5, a dryer vibration device includes a drum 1, a fixed sleeve 20 with an air inlet 18 and a discharge port 11 arranged on one side of the drum 1, and a fixed sleeve 20 arranged on the other side of the drum 1 The air outlet 19 and the feed port 6, the transmission gear 3 arranged on the outer wall of the drum 1, the reducer 9 connected with the transmission gear 3 through the gear, the motor 12 connected with the reducer 9 through the pulley, and the transmission gear 3 arranged on the The sliding wheel 2 on the outer wall of the drum 1 on both sides is matched with the roller shaft 10. It is characterized in that: the outer wall of the drum 1 is movably installed with a vibrating hammer 4 through the support frame 5, and a filter bucket is arranged in the middle of the inner wall of the drum 1. 13. The inner wall of the drum 1 on both sides of the filter bucket 13 is provided with a forward lifting board 15, and the inner wall...

Embodiment 3

[0026] Embodiment 3: as figure 1 , 2 , 3, 4, and 5, a dryer vibration device includes a drum 1, a fixed sleeve 20 with an air inlet 18 and a discharge port 11 arranged on one side of the drum 1, and a fixed sleeve 20 arranged on the other side of the drum 1 The air outlet 19 and the feed port 6, the transmission gear 3 arranged on the outer wall of the drum 1, the reducer 9 connected with the transmission gear 3 through the gear, the motor 12 connected with the reducer 9 through the pulley, and the transmission gear 3 arranged on the The sliding wheel 2 on the outer wall of the drum 1 on both sides is matched with the roller shaft 10. It is characterized in that a vibrating hammer 4 is movably installed on the outer wall of the drum 1 through a support frame 5, and a filter bucket is arranged in the middle of the inner wall of the drum 1. 13. The inner wall of the drum 1 on both sides of the filter bucket 13 is provided with a forward flight board 15, and the reverse flight b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com