Pharmaceutical nano crystallization tank and crystallization method

A technology of nano-crystallization and crystallization tanks, which is applied in the field of crystallization tank manufacturing, can solve problems such as low crystallization efficiency and inability to realize wind-driven crystallization, and achieve high crystallization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

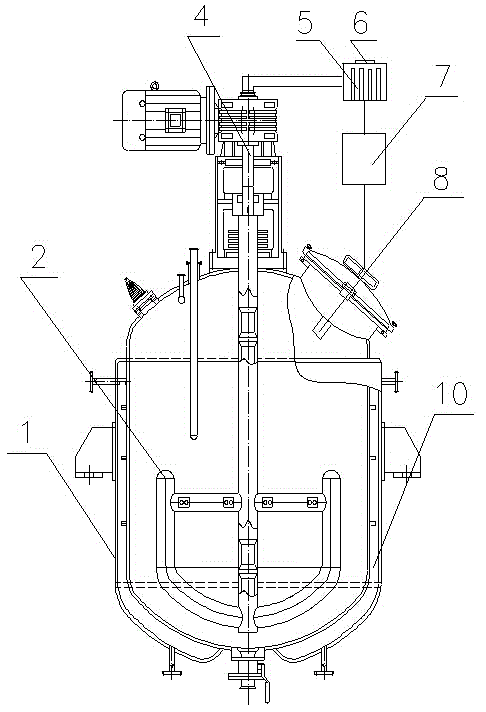

[0009] Example 1: Refer to the attached figure 1 . A medicinal nano crystallization tank, which includes a crystallization tank. The wall of the crystallization tank body 1 is an interlayer wall 10. The interlayer wall 10 is provided with a fluid inlet and a fluid outlet and forms a loop with a subcooled air refrigerator 5. The wall surface is uneven and rough, and the uneven rough surface is provided with a nano layer, and the surface of the nano layer is uneven; the inner wall of the sandwich has uneven rough surface and the uneven nano layer on the uneven rough surface. The manufacturing process is existing The technology is not described here. The crystallization tank 1 is provided with a subcooling agitator 2, the shaft and U-shaped stirring teeth of the agitator are in a hollow tubular structure and are fixed on the upper part of the crystallization tank 1 by a bearing positioning frame, and are driven to rotate by a motor 1. The hollow pipe stirring shaft 4 is connecte...

Embodiment 2

[0010] Embodiment 2: On the basis of embodiment 1, a non-adhesive pneumatic crystallization method for medicinal nano crystallization tanks. First, the temperature controller 7 sets the required crystallization temperature of the material, and then the temperature controller 7 commands The cold air cooler 5 cools the air drawn by the exhaust fan. Since the material is in a non-adhesive fit with the 1 nanometer inner wall surface of the crystallization tank, the subcooled air cooler 5 passes through the cold air conveying pipe to the hollow tube stirring shaft 4 and the interlayer at the same time The multiple air-cooled pipes on the wall 10 and the inner wall of the sandwich wall pressurize and convey the supercooled cold air. One is to force the temperature in the crystallization tank 1 to drop sharply. At the same time, the multiple air-cooled pipes and hollow U-shaped stirring teeth on the inner wall of the sandwich wall Multiple sub-cooled air discharge blow holes on the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com