Nano aluminum oxide coating process for preventing quartz glass from high-temperature deformation and adhesion

A technology of nano-alumina and quartz glass, applied in the direction of coating, etc., to achieve the effect of increasing the number of times of use, eliminating high-temperature adhesion, and reducing the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

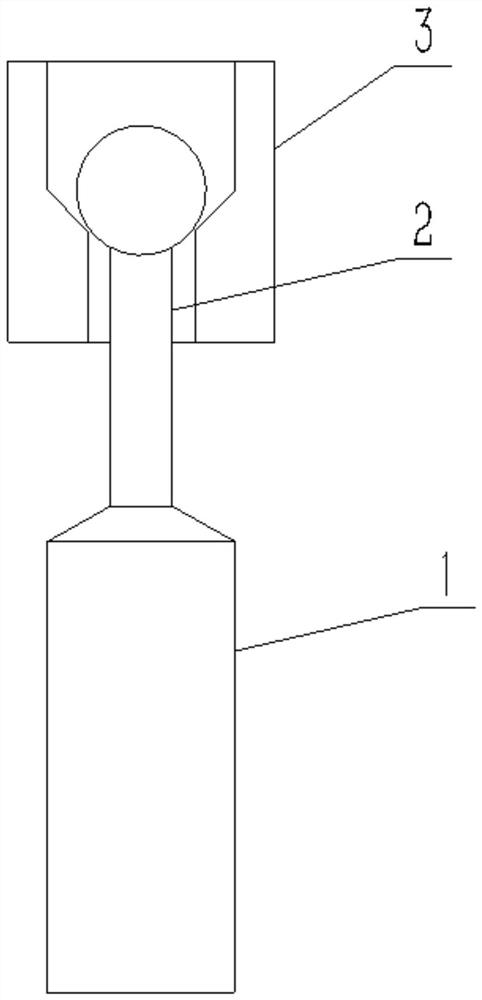

Image

Examples

Embodiment 1

[0027] A nano-alumina coating process for preventing high-temperature deformation and adhesion of quartz glass, comprising the following steps:

[0028] Step 1: Select high-purity nano-alumina, nano-zirconia, and nano-silicon carbide, and mix them into powder in proportion;

[0029] Step 2: Through the high-temperature sintering process, the powder is uniformly sintered on the surface of the quartz glass sphere to form a coating. The attachment can be effectively combined with the quartz glass to reach the nano-level level, which greatly improves the strength and toughness of the coating, thereby improving the surface resistance of the quartz glass. Temperature, glass strength and toughness;

[0030] Step 3: Control the thickness of the coating at 18um, and then bake it with a flame to make the bonding force of the coating reach 30Mpa and increase the wear resistance of the attached surface;

[0031] Step 4: Finally, stress-relieving the quartz glass.

[0032] Specifically, ...

Embodiment 2

[0035] A nano-alumina coating process for preventing high-temperature deformation and adhesion of quartz glass, comprising the following steps:

[0036] Step 1: Select high-purity nano-alumina, nano-zirconia, and nano-silicon carbide, and mix them into powder in proportion;

[0037] Step 2: Through the high-temperature sintering process, the powder is uniformly sintered on the surface of the quartz glass sphere to form a coating. The attachment can be effectively combined with the quartz glass to reach the nano-level level, which greatly improves the strength and toughness of the coating, thereby improving the surface resistance of the quartz glass. Temperature, glass strength and toughness;

[0038] Step 3: Control the thickness of the coating at 19um, and then bake it with a flame to make the bonding force of the coating reach 40Mpa and increase the wear resistance of the attached surface;

[0039] Step 4: Finally, stress-relieving the quartz glass.

[0040] Specifically, ...

Embodiment 3

[0043] A nano-alumina coating process for preventing high-temperature deformation and adhesion of quartz glass, comprising the following steps:

[0044] Step 1: Select high-purity nano-alumina, nano-zirconia, and nano-silicon carbide, and mix them into powder in proportion;

[0045] Step 2: Through the high-temperature sintering process, the powder is uniformly sintered on the surface of the quartz glass sphere to form a coating. The attachment can be effectively combined with the quartz glass to reach the nano-level level, which greatly improves the strength and toughness of the coating, thereby improving the surface resistance of the quartz glass. Temperature, glass strength and toughness;

[0046] Step 3: Control the thickness of the coating at 20um, and then bake it with a flame to make the bonding force of the coating reach 50Mpa and increase the wear resistance of the attached surface;

[0047] Step 4: Finally, stress-relieving the quartz glass.

[0048] Specifically, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com