Multipoint temperature detecting system with liquid level measuring function

A multi-point temperature and detection system technology, applied in the direction of liquid level indicators, thermometers, measuring devices, etc. for physical variable measurement, can solve the problems of expensive, meaningless, unable to independently output temperature data, etc., to expand the application area, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

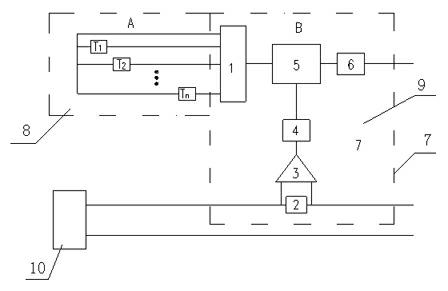

[0014] Such as figure 1 As shown, the temperature sensing unit is a multi-point temperature sensor 8 distributed in different liquid level positions, such as figure 1 T in 1 , T 2 , T N ,T 1 , T 2 , T N It is electrically connected with the processing unit 9 . The processing unit 9 includes: a temperature acquisition module 1, a liquid level sampler 2, an isolation amplifier 3, an A / D conversion module 4, a data processing module 5, an output module 6 and a housing, the temperature acquisition module 1, the liquid level sampler 2, The isolation amplifier 3, the A / D conversion module 4, the data processing module 5, and the output module 6 are on the circuit board in the casing 7, T 1 , T 2 , T N They are respectively electrically connected to the temperature acquisition module 1, and the temperature acquisition module 1 collects the temperature of the liquid sensed by the temperature sensors 8 at different positions in the liquid, and then transmits it to the data pro...

Embodiment 2

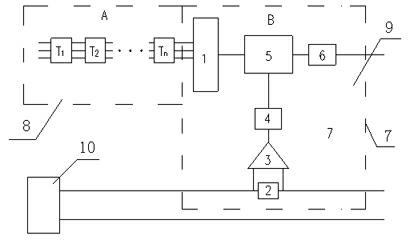

[0016] Such as figure 2 As shown, the temperature sensing unit is a multi-point temperature sensor 8 distributed in different liquid level positions, such as figure 1 T in 1 , T 2 , T N ,T 1 , T 2 , T N It is electrically connected with the processing unit 9 . The processing unit 9 includes: a temperature acquisition module 1, a liquid level sampler 2, an isolation amplifier 3, an A / D conversion module 4, a data processing module 5, an output module 6 and a housing, the temperature acquisition module 1, the liquid level sampler 2, The isolation amplifier 3, the A / D conversion module 4, the data processing module 5, and the output module 6 are on the circuit board in the casing 7, T 1 , T 2 , T N They are respectively electrically connected to the bus, and electrically connected to the temperature acquisition module 1 through the bus. The temperature acquisition module 1 collects the temperature of the liquid sensed by the temperature sensor 8 at different positions i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com