Preparation of ultralow-carbon sheet metallographic phase sample and tissue display method

A display method and ultra-low carbon technology, applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problem of blurred pictures, incomplete display of ferrite grains, and inability to take high-quality clear pictures, etc. problem, to achieve the effect of high definition and simple preparation method

Active Publication Date: 2011-06-15

SHOUGANG CORPORATION

View PDF5 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

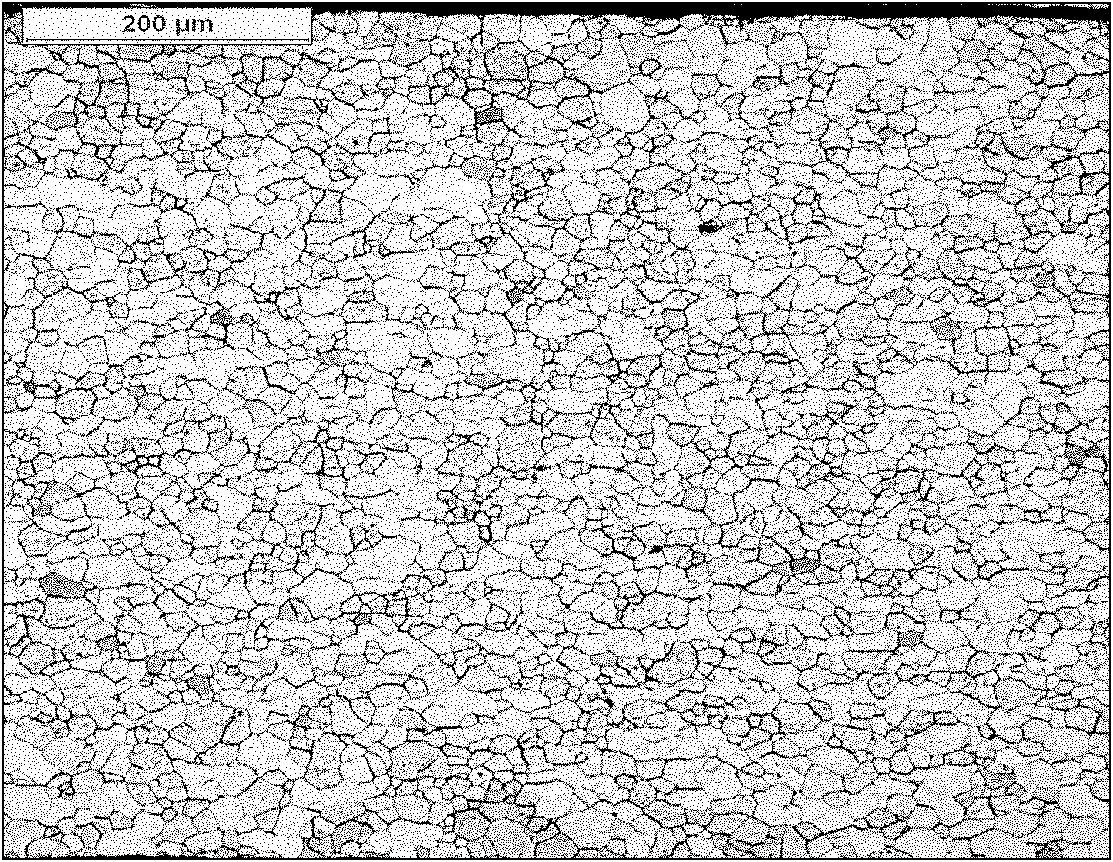

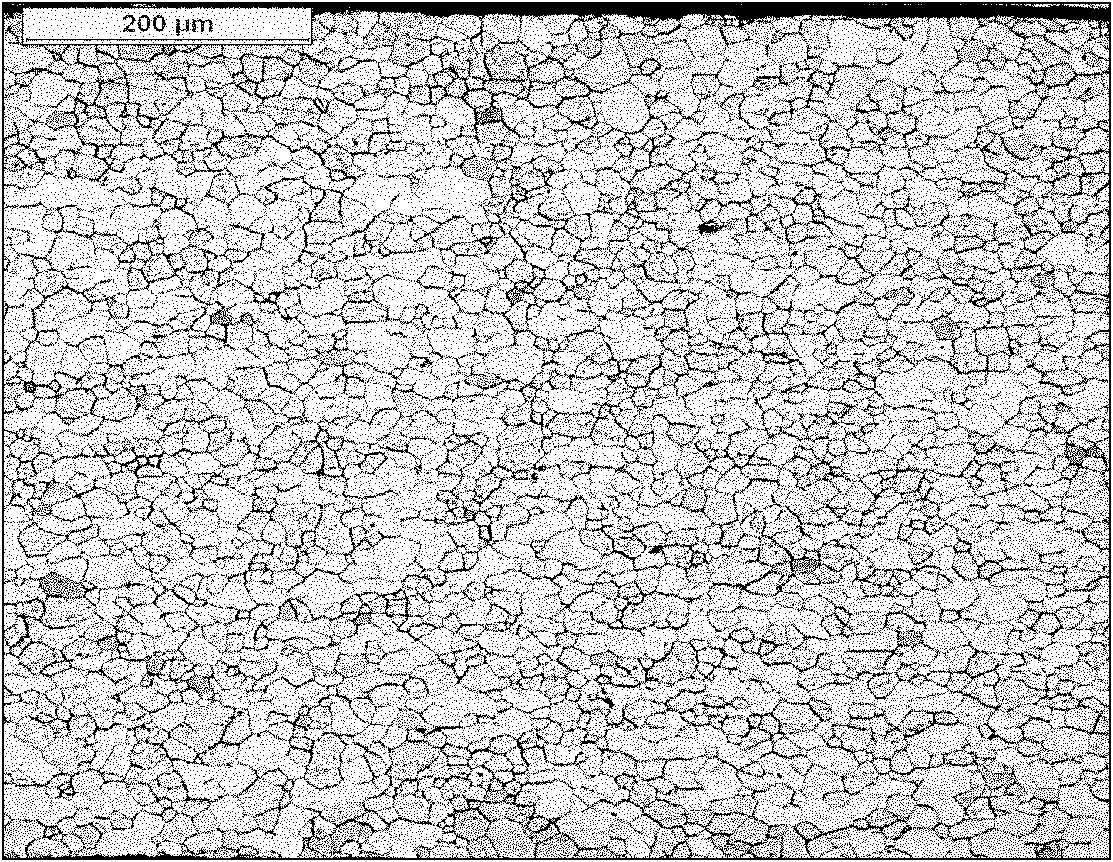

It was found that none of the ferrite grains could be fully displayed, the picture was blurred, and high-quality clear pictures could not be taken

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a preparation method of an ultralow-carbon sheet metallographic phase sample and a tissue display method, belonging to the technical field of preparation of metallographic phase samples. The preparation method of the ultralow-carbon sheet metallographic phase sample comprises four steps of embedding, grinding, polishing and corrosion of the sample. The preparation method has the advantages of being simple to operate, being capable of obtaining sheet tissue pictures with clear materials, solving the problem of difficult display of the ultralow-carbon sheet, and being applicable to sheets the metallographic phase tissue is pure ferrite.

Description

Preparation and structure display method of metallographic sample of ultra-low carbon thin plate technical field The invention belongs to the technical field of metallographic sample preparation, and in particular provides a method for preparing an ultra-low carbon sheet metallographic sample and displaying its structure. It is mainly used to prepare metallographic samples of ultra-low carbon thin plates, and is suitable for thin plates whose metallographic structure is pure ferrite. Background technique Ultra-low-carbon thin plates such as ultra-low-carbon IF steel adopt advanced smelting technology to reduce the carbon content of the steel (<0.006%), and add Ti and Nb elements to fix C and N elements, thereby obtaining pure ferrite without interstitial atoms body steel. The ferritic steel in IF has excellent deep drawing performance, excellent plastic strain ratio, good elongation and non-aging performance, which can meet the needs of the automobile industry for comp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N1/32G01B11/00

Inventor 刘晓岚温娟刘卫平李瑰珅

Owner SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com