Installation method of SF6 gas breaker

A technology of gas circuit breaker and installation method, which is applied in the direction of high-voltage air circuit breaker, circuit, switchgear, etc., can solve the problems of personal electric shock hazard, long power outage time, mechanical damage, etc., and achieve reduced power outage time, small workload, Avoid freezing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

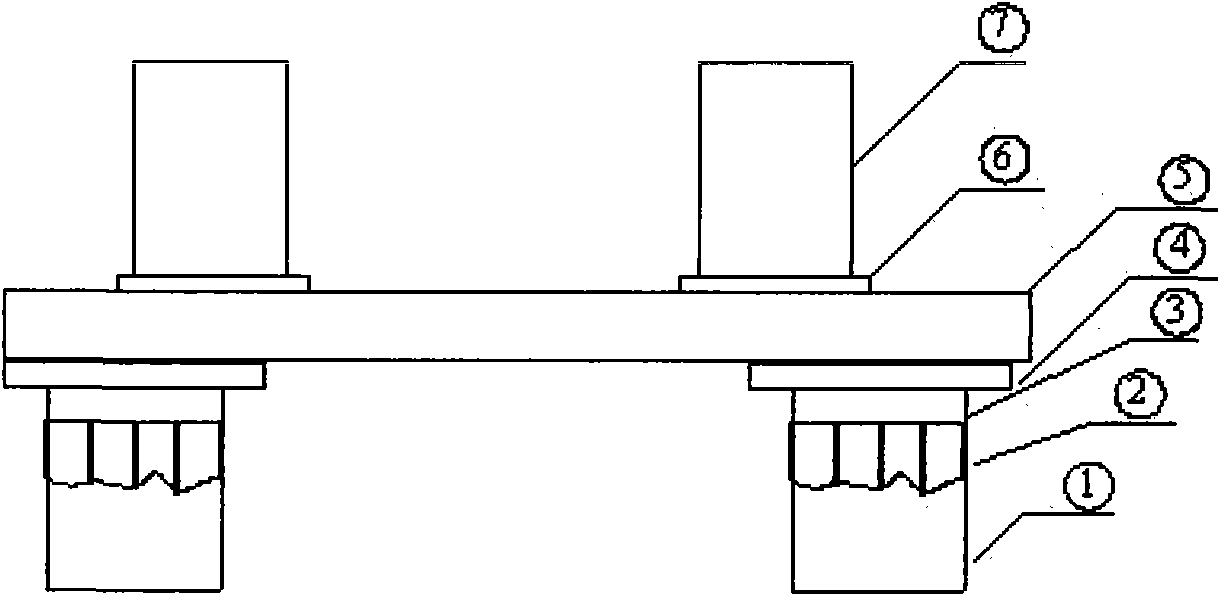

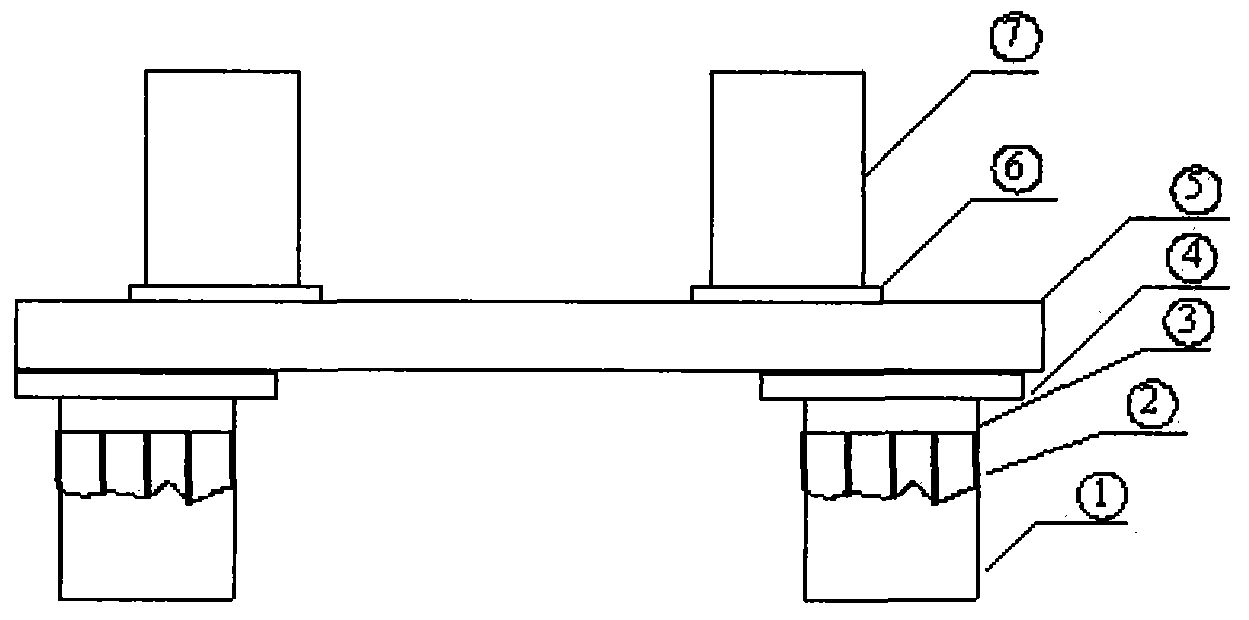

[0010] exist figure 1 Among them, the cement rod steel bar (2) is welded with the support ring (3), and a square support iron plate (4) is welded on the support ring as the foundation of the channel steel, and a channel steel (5) is welded on both sides of the support iron plate as the For the foundation of the SF6 circuit breaker, a square iron plate (6) is welded on the channel steel and drilled to install the SF 6 Base. At the same time, dig 1 meter deep around the original cement pole foundation and fill it with furnace ash to keep warm. At the same time, it can also reduce the moisture content of the soil and avoid the skewing of the pole tower due to the occurrence of soil freezing and swelling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com