Multi-functional motor

A multifunctional, generator technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of not being able to be used as a motor at the same time, not conforming to environmental protection, energy saving and emission reduction, and high equipment investment, so as to reduce magnetic field leakage, less investment, and reduce The effect of energy waste

Inactive Publication Date: 2011-06-15

刘荣坤

View PDF11 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The single-phase and multi-phase generators currently used by people are generally generated by hydraulic turbines, steam turbines, fuel-powered engines or other prime movers to drive generators to generate electricity, and the generated electricity is sent to the grid or directly supplied to electrical equipment. The generator here is only used as a single power generation equipment, and cannot be used as a motor at the same time. In real life, generators and motors are often used at the same time, which requires the configuration of generators and motors at the same time. The investment in equipment is high. The input or output of electric energy is also large during operation, the operating cost is high, and it is easy to cause energy waste, which does not meet the requirements of today's environmental protection, energy saving and emission reduction.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

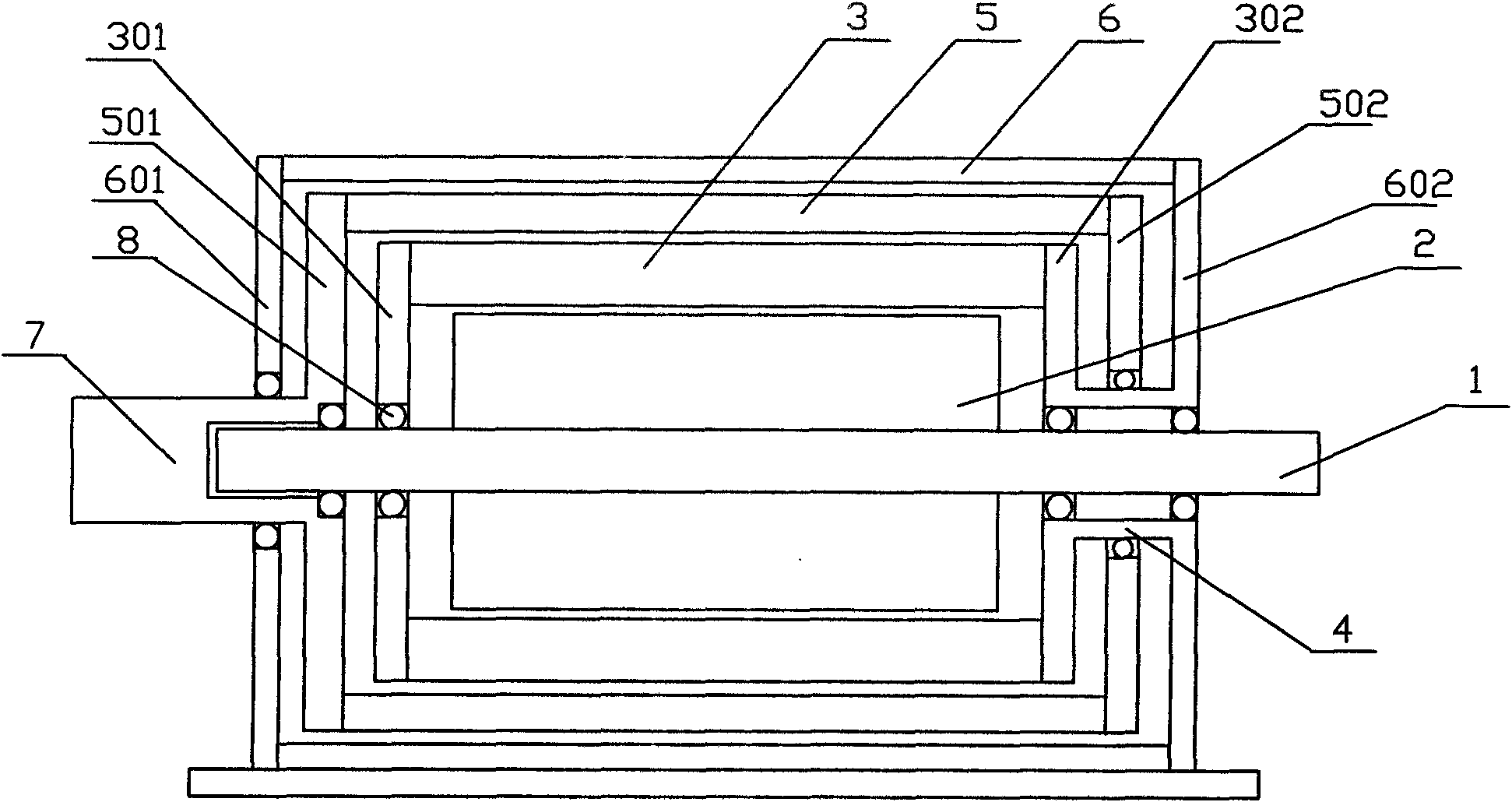

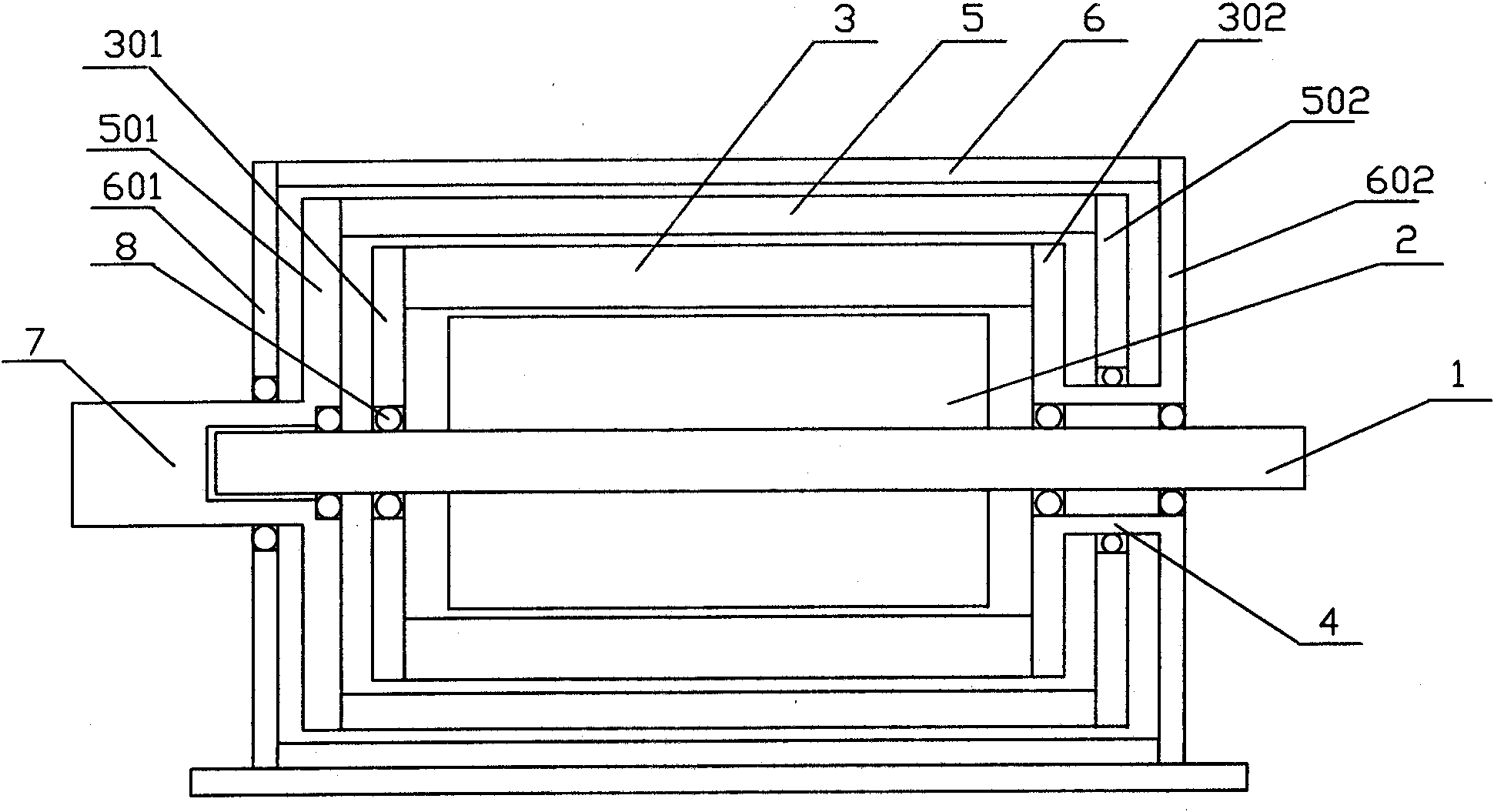

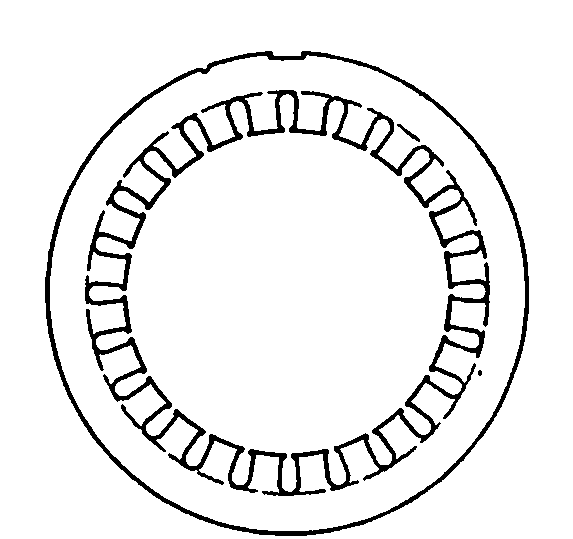

The invention provides a multi-functional motor. The motor comprises stators, a first rotor shaft, first rotors, two end covers, other conventional motor accessories, second rotors and a rotor shaft fixing the second rotors, wherein the stators are arranged between the first rotors and the second rotors; micro yoke height or zero yoke height is set for the stator core; the two rotor shafts are respectively connected with the first rotors and the second rotors, respectively extend heads toward the outside of the end covers at the two sides of the motor body and are respectively connected with a mechanical transmission shaft needing power so as to provide power to the outside; the first rotors and the second rotors can interchange to respectively serve as the rotors of a generator and the rotors of an electric motor; and according to the reversibility principle of the electric motor and the generator, the two kinds of rotors can serve as the stators of the motor and the stators can serve as the rotors of the motor. The multi-functional motor has the following beneficial effects: the motor is used for composing the electric motor to be used; and the motor can not only serve as the generator which generates power normally but also serve as the electric motor when the machines need to be dragged to do work, thus realizing that one machine has multiple purposes, effectively saving the equipment cost and saving energy and reducing emission.

Description

A multifunctional motor (1) Technical field: The invention relates to a design technology of a motor (including a generator or a motor), in particular to a high-efficiency and multi-purpose multifunctional motor, which belongs to the technical field of motors. (two) background technology: The single-phase and multi-phase generators currently used by people are generally generated by hydraulic turbines, steam turbines, fuel-powered engines or other prime movers to drive generators to generate electricity, and the generated electricity is sent to the grid or directly supplied to electrical equipment. The generator here is only used as a single power generation equipment, and cannot be used as a motor at the same time. In real life, generators and motors are often used at the same time, which requires the configuration of generators and motors at the same time. The investment in equipment is high. The input or output electric energy required for operation is also large, the o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02K16/02H02K16/04

Inventor 刘荣坤

Owner 刘荣坤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com