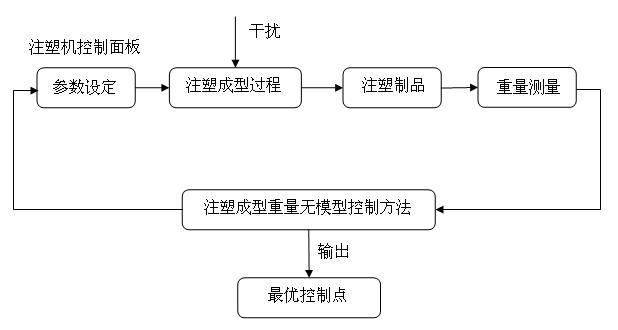

Model-free weight controlling method for injection molding product

A technology of injection molding and control method, which is applied in the field of model-free control of injection molding product weight, and can solve problems such as low efficiency, sensitivity to noise and interference, and inability to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] The following uses the weight control of a plastic magnifying glass handle as an example to illustrate the implementation process of a model-free weight control method for injection molded products proposed by the present invention.

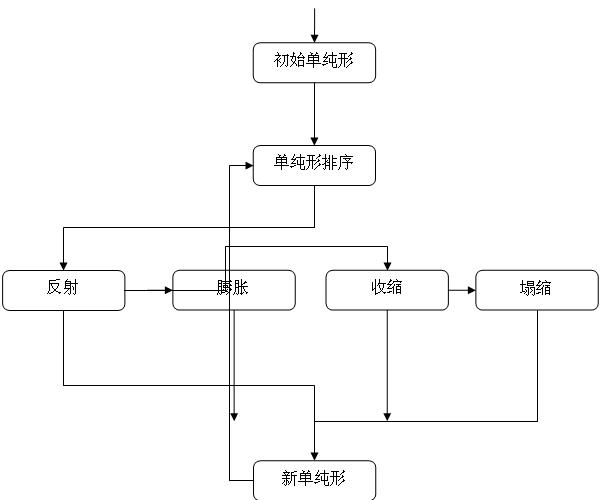

[0056] First, enter step (1) to initialize the method; the weight control target of the product =6.5 grams, according to the weight fluctuation of the product, set the weight deviation tolerance Grams, Weight Fluctuation Variance Tolerance grams, number of repetitions , the number of repeated measurements , the number of validation trials , the maximum number of trials , the coefficients of the simplex algorithm ; The optimized process parameters are: injection pressure, holding pressure and holding time, in which the injection section is divided into one section and two sections to be controlled respectively, and the subsection point is also a key process parameter. In this way, a total of 5 process parameters need to be adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com