Hydraulic one-way valve

A technology of hydraulically controlled one-way valves and one-way valves, which is applied in the direction of control valves, valve devices, and functional valve types, etc., and can solve the problems of inconvenient use, troublesome process, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and specific embodiments.

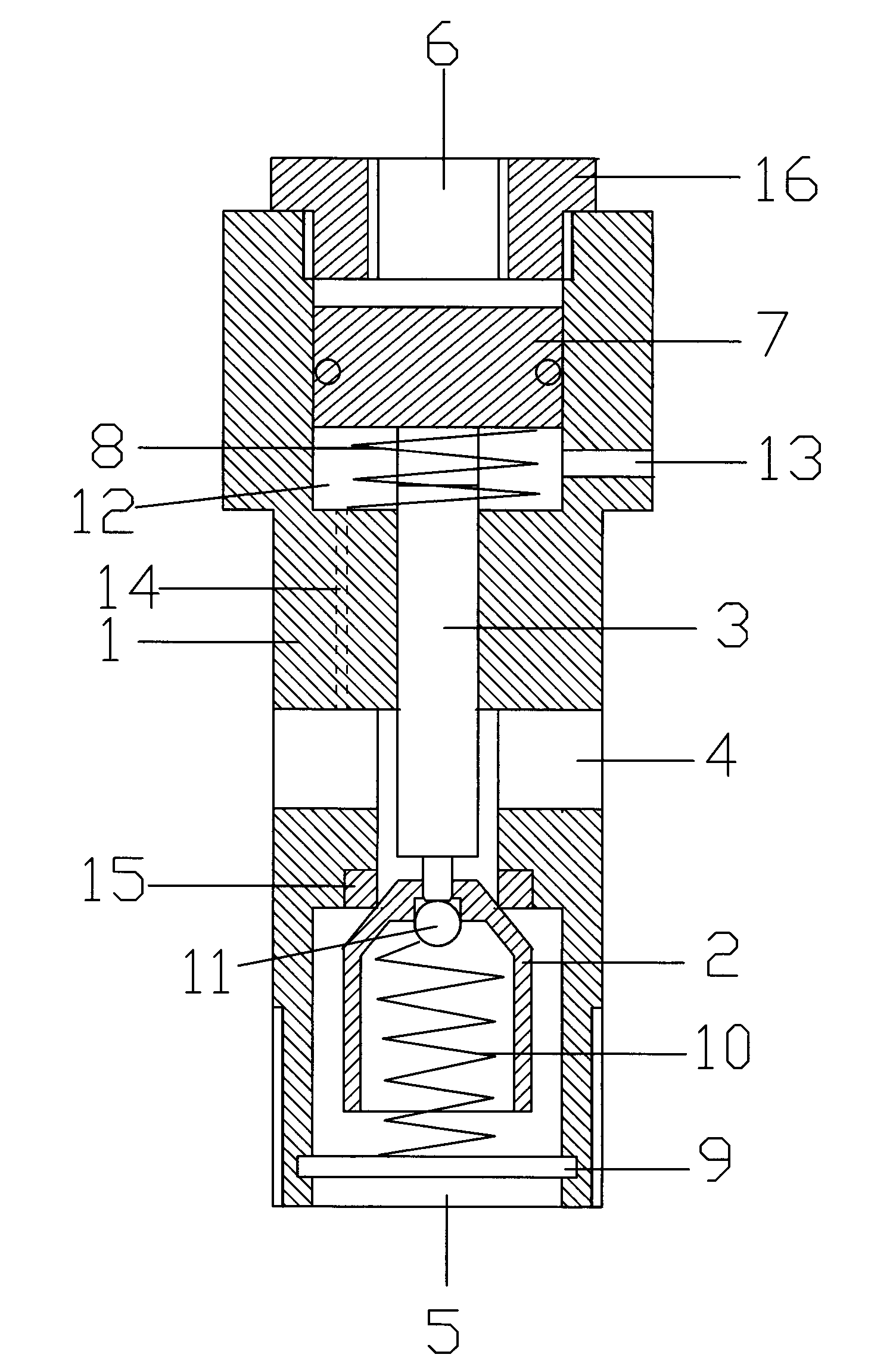

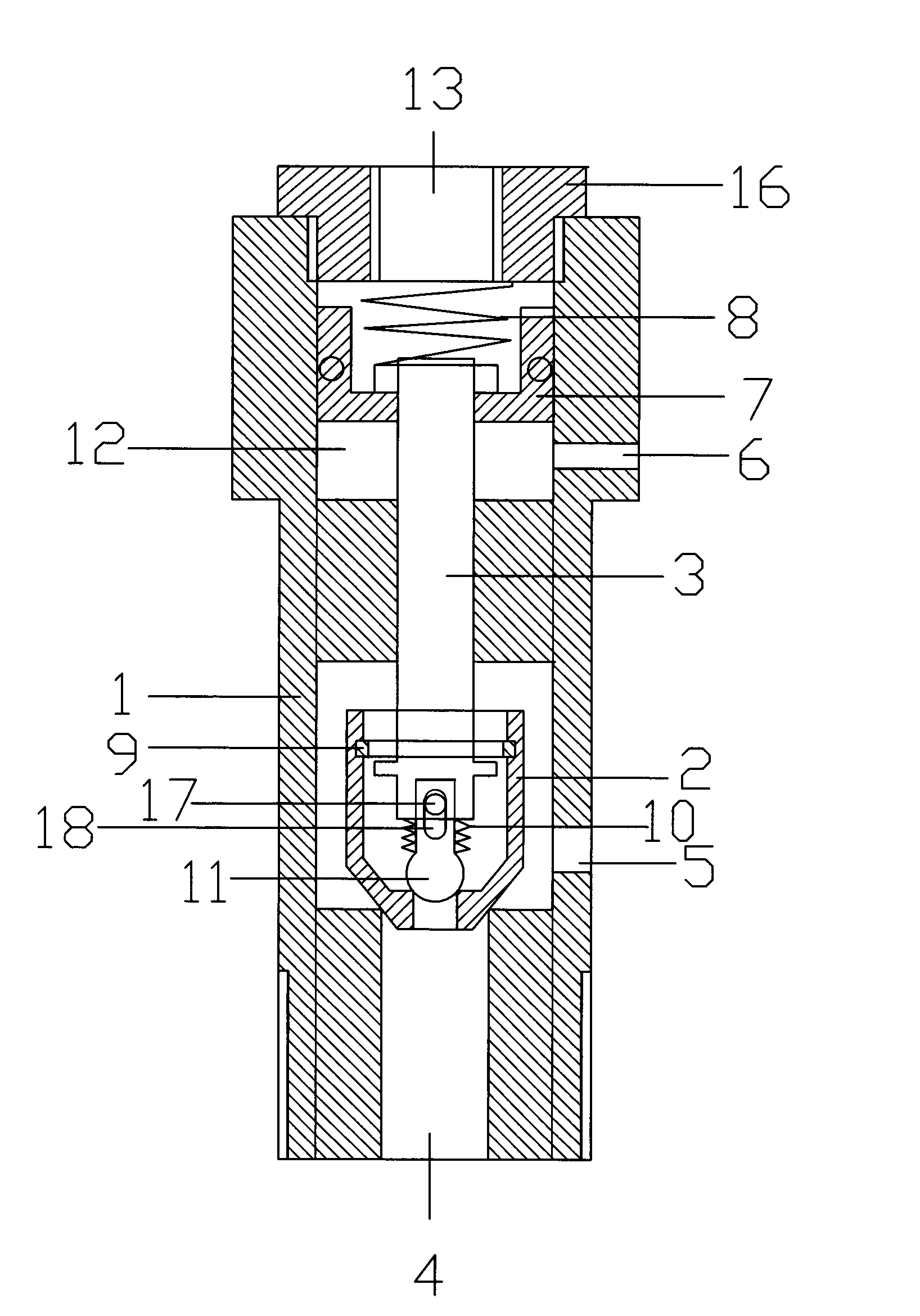

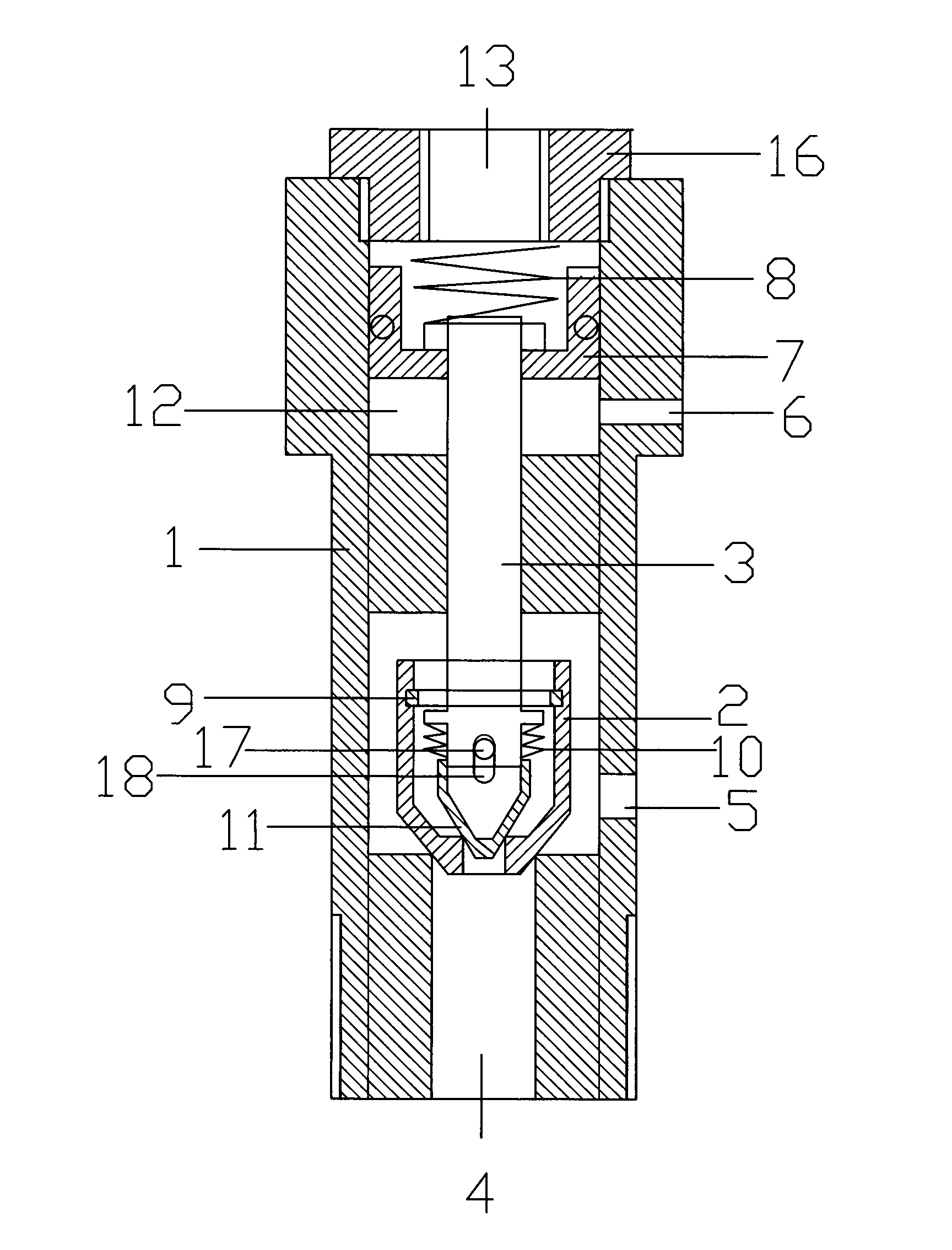

[0019] The hydraulic control one-way valve of the present invention includes a valve body 1, a main valve core 2 and an ejector rod 3. The valve body 1 is provided with a liquid inlet 4, a liquid outlet 5, a control liquid inlet 6 and a liquid drain channel. , The main valve core 2 and the ejector rod 3 are arranged in the valve body 1.

[0020] The outer diameter of the upper head of the valve body 1 is greater than the outer diameter of the lower part of the head, the lower part of the valve body 1 is provided with external threads, and the valve wall of the lower part of the valve body is provided with There are several transverse passages through which the valve body passes up and down; the upper part of the mandrel 3 is provided with a control piston 7, and the control piston 7 is also provided with a spring II8. One end of the spring II8 is fixed on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com