Car foot mat cutting machine with adjusting function

A technology for car mats and cutting machines, applied in metal processing and other directions, can solve the problems affecting the cutting of mats with different thicknesses, inability to tilt the tool, inability to adjust, etc., to improve the fixing effect, increase stability, and facilitate adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

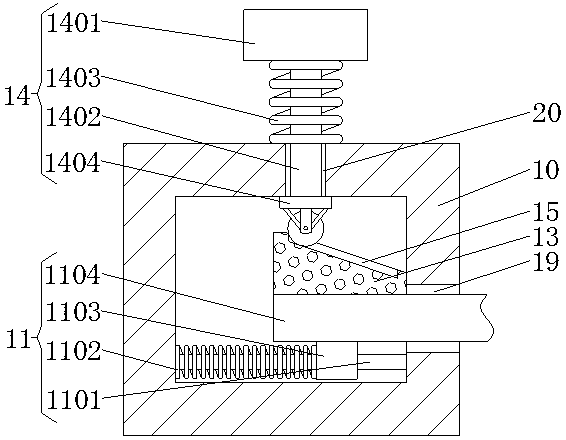

[0040] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

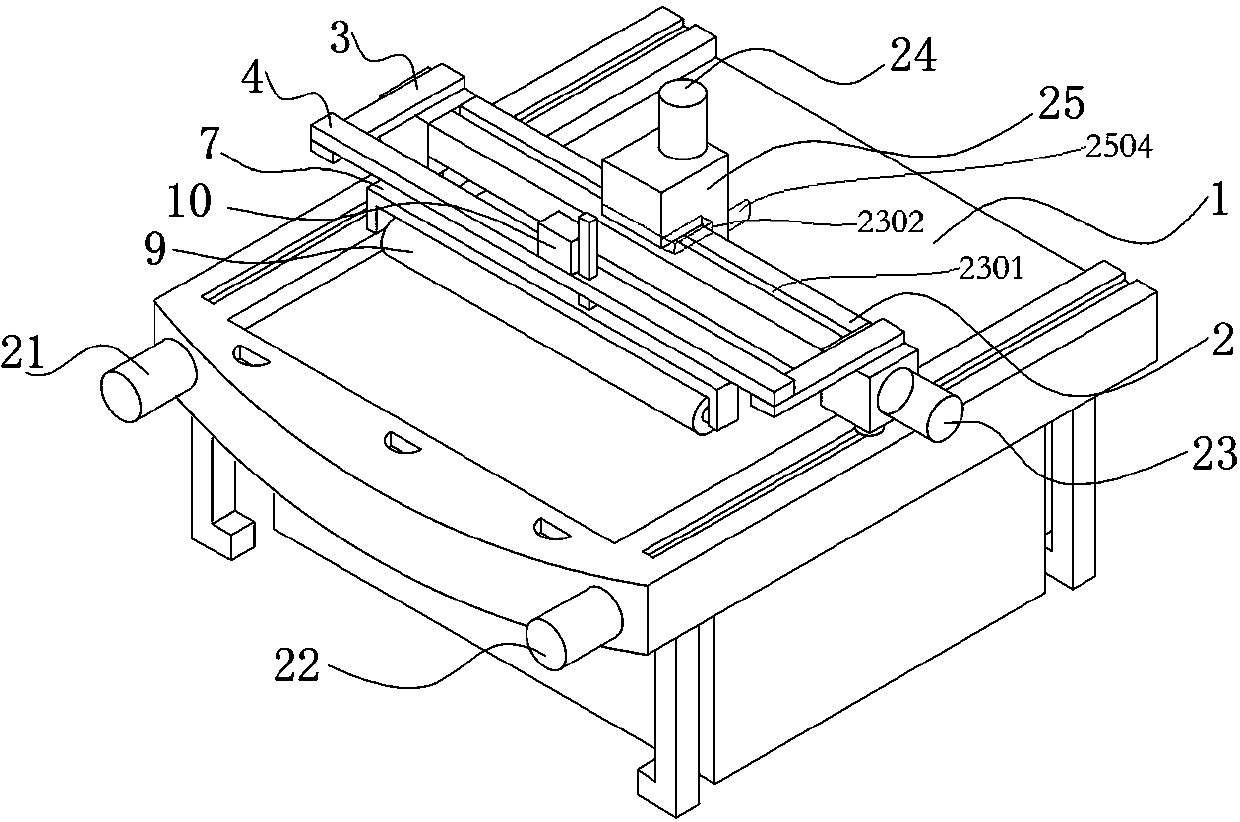

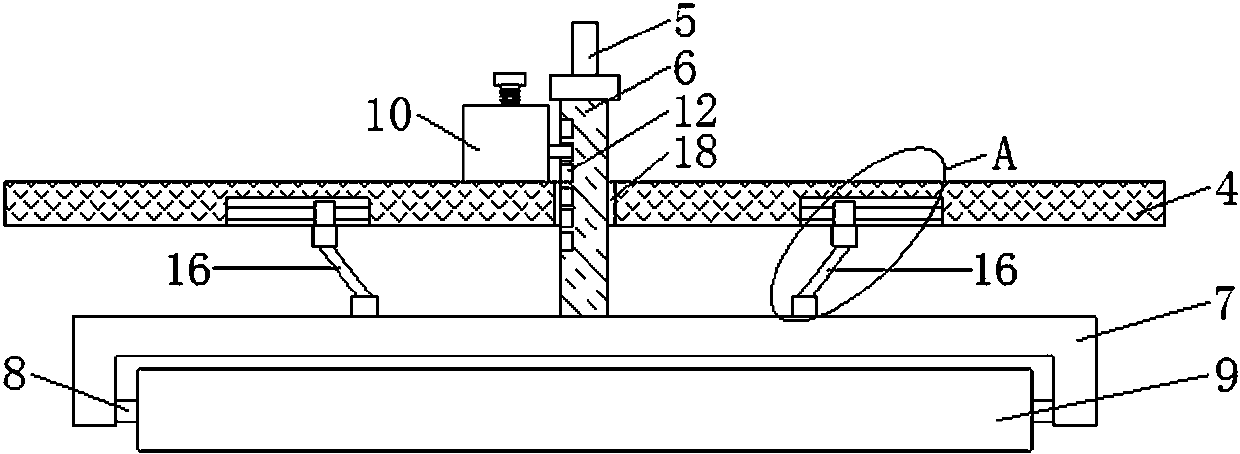

[0041] Refer to attached Figure 1-7 , a car mat cutting machine with adjustment function includes a workbench 1, a cutting device, a cutting transmission mechanism, a pull ring 5, a fixing plate 3, a bracket 7, a connecting plate 4, a fixing roller 7, a housing 10, a fixing mechanism, Block 13, adjusting mechanism 14, stabilizing mechanism 16.

[0042] Described cutting transmission mechanism comprises gantry 2, gantry transmission motor one 21, transmission screw one, transmission nut one, slide block one, guide rail one 2101, gantry transmission motor two 22, transmission screw two, transmission nut two, Slide block two, guide rail two 2201.

[0043] Both sides of the workbench are respectively provided with guide rail one 2101, guide rail two 2201, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com