Flexible joint leakage oil collecting device for plane fuel duct

A collection device and flexible joint technology, applied in the direction of pipe/pipe joint/pipe fitting, pipe element, adjustable connection, etc., can solve the problem of inconsistent bending deformation between oil leakage collection device and flexible joint, axial limit deformation of aircraft fuel conduit, flexibility Joint loss of bending ability and other problems, to solve the problem of oil leakage of flexible joints, ensure the safety of aircraft use and flight, and work reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

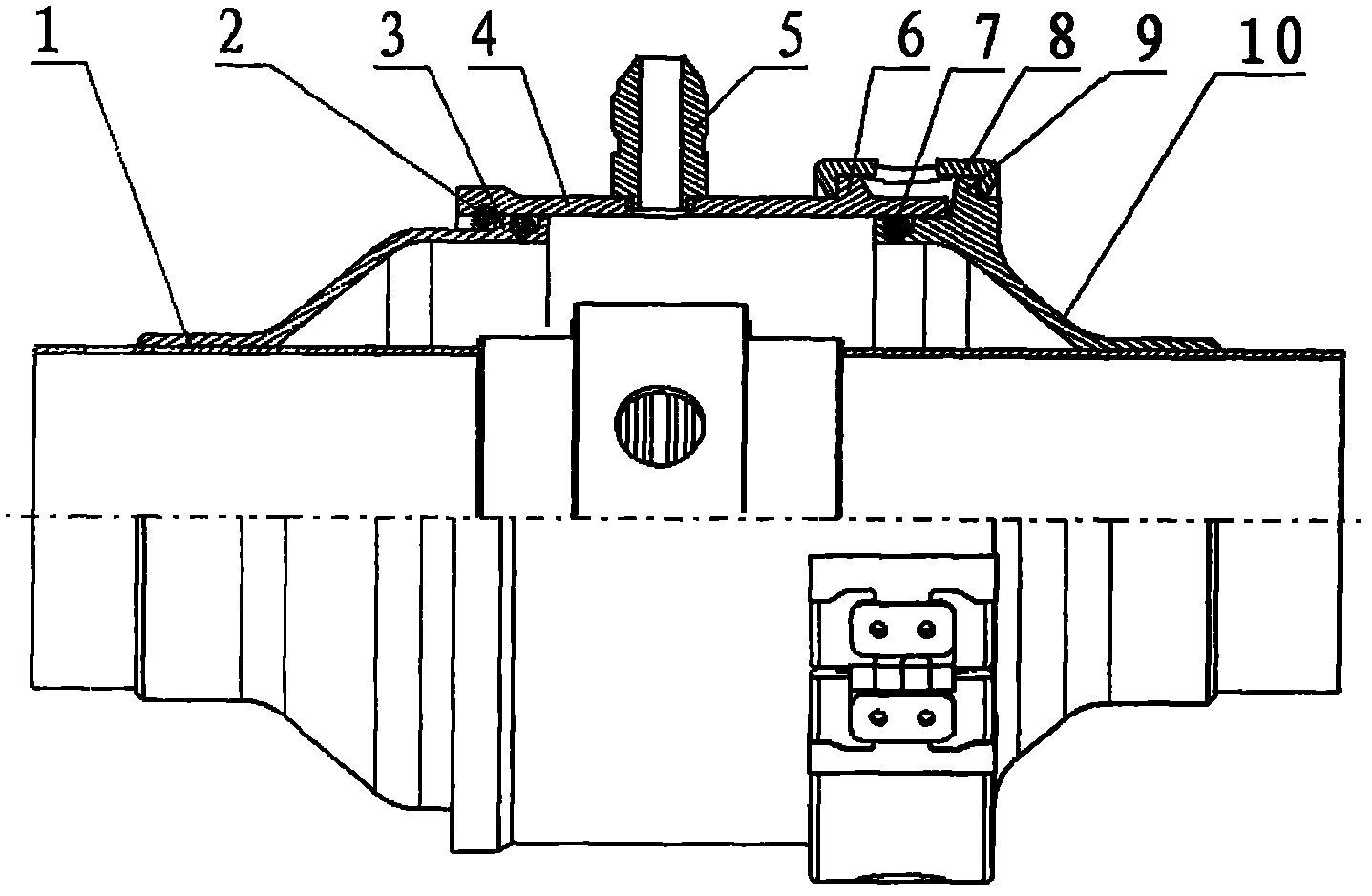

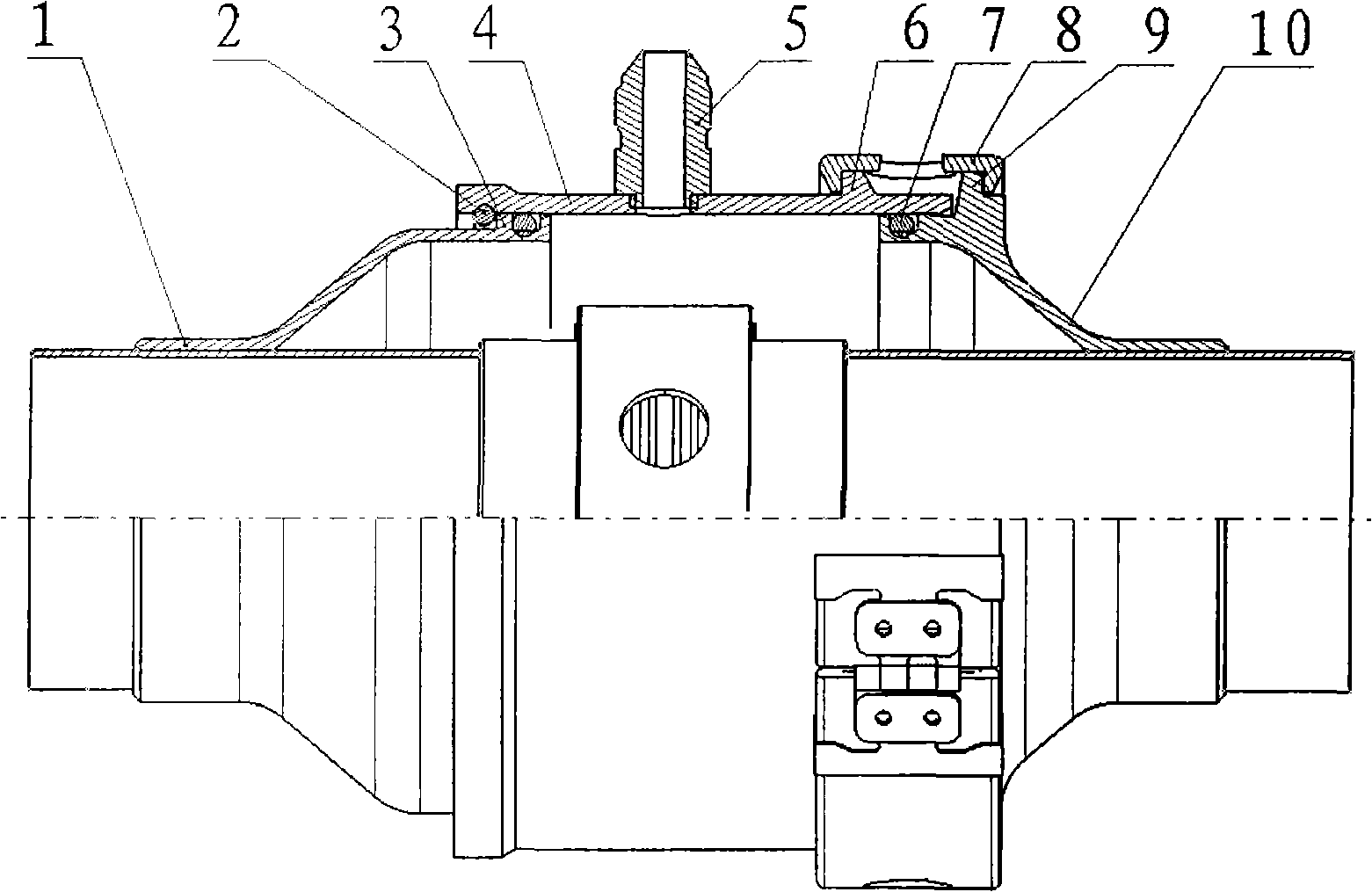

[0011] The present invention comprises a left supporting sleeve 1, a spring retaining ring 2, a block 3, a connecting sleeve 4, an oil leakage nozzle 5, a left flange 6, a sealing ring 7, a hoop 8, a right flange 9, and a right supporting sleeve 10. One end of the left support sleeve 1 and one end of the right support sleeve 10 are respectively welded on the aircraft fuel conduits at the left and right ends of the flexible joint. The other end of the support sleeve 10 is provided with a sealing groove, and the outer side of the sealing groove is provided with a right flange 9 for installing a clip; one end of the connecting sleeve 4 is provided with a card slot for installing a spring retaining ring 2, and the other end is provided for installing a clip The left flange 1 of the hoop 8, the connecting sleeve 4 are installed on the left supporting sleeve 1 and the right supporting sleeve 10 through the clamping hoop 8 and the spring retaining ring 2, the oil leakage nozzle 5 is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com