Oblate staggered pipe for heat exchanger

A heat exchanger and flat tube technology, which is applied in the field of chemical equipment manufacturing, achieves the effects of less scaling, enhanced heat transfer process, and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

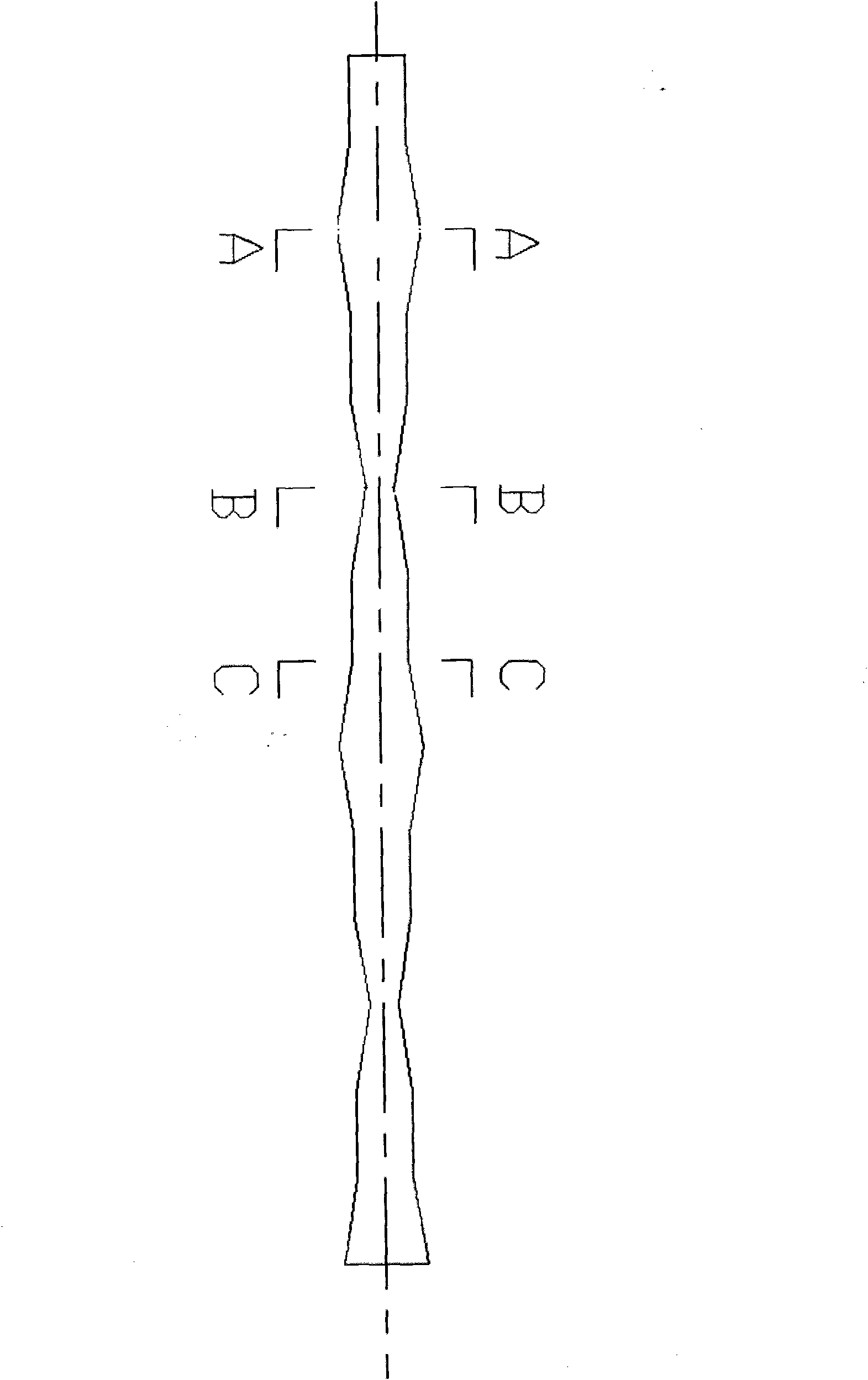

[0019] A kind of oblate and round interlaced tubes used in heat exchangers. The round tubes in the shell and tube heat exchanger are replaced by oblate and round interlaced tubes as heat exchange elements. There is no baffle in the tube bundle, and the heat exchange tubes maintain point contact. Play a mutual support role, and form a wave-like flow between the heat exchange tubes, form a staggered turbulent flow, and obtain strong agitation, thereby greatly intensifying the heat transfer process.

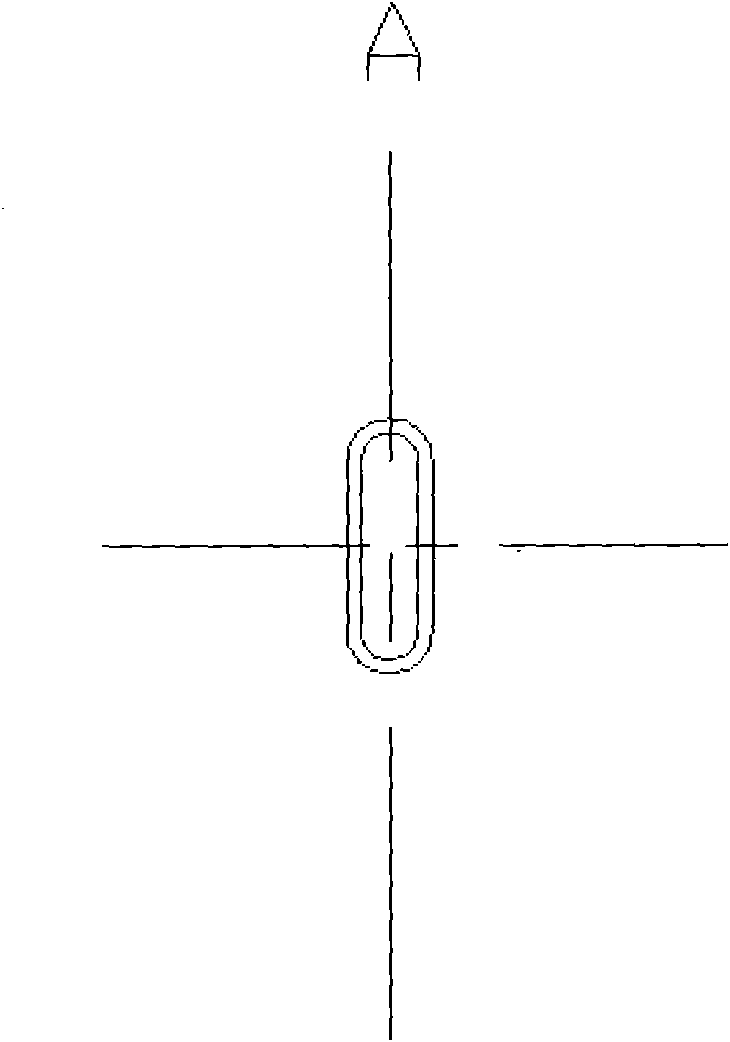

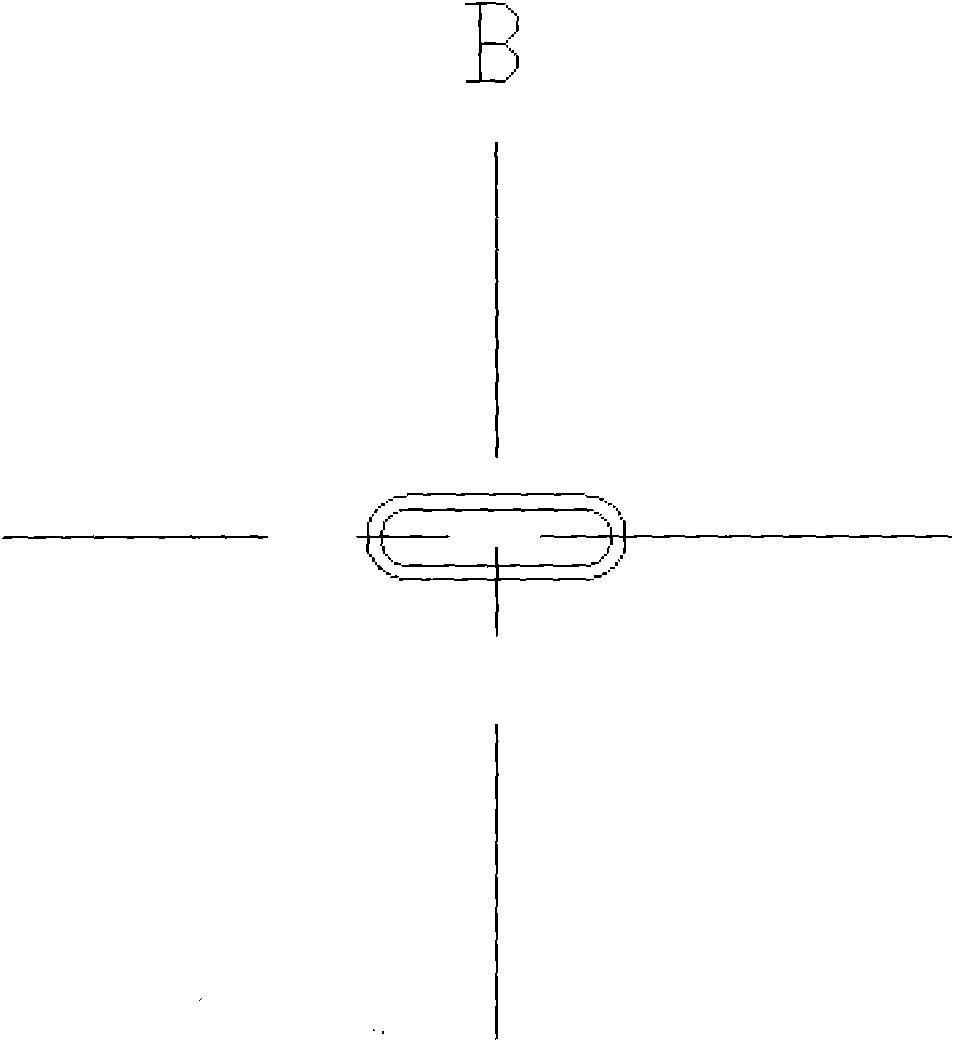

[0020] exist figure 1 Among them, the oblate and round interlaced pipes (2) are formed sequentially from flat pipes, round pipes, flat pipes, flat pipes, round pipes, and flat pipes. Each section has the same length, and the two adjacent flat pipes are perpendicular to each other. The tube gradually transitions to a round tube in a tapered shape, and two adjacent flat tubes transition in a tapered and parallel manner to the maximum cross-section of each other. When used in a heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com