Improved high-voltage cable connector for underground transformer

A high-voltage cable and transformer technology, applied in the field of electricity, can solve the problems that buried transformers cannot be used, and the protection level of the shell cannot meet the IP68 standard, so as to achieve the effect of improving internal insulation capacity and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

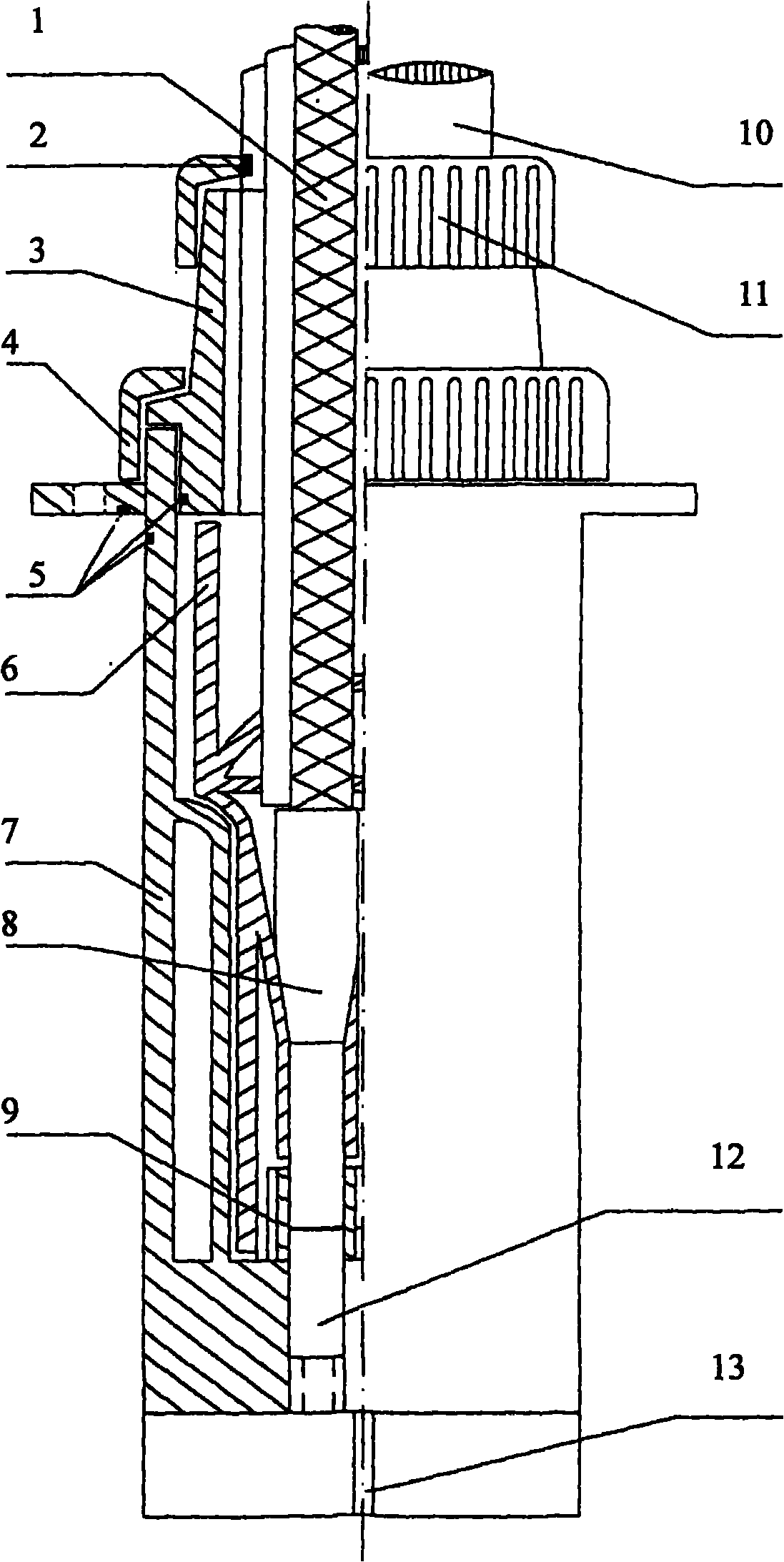

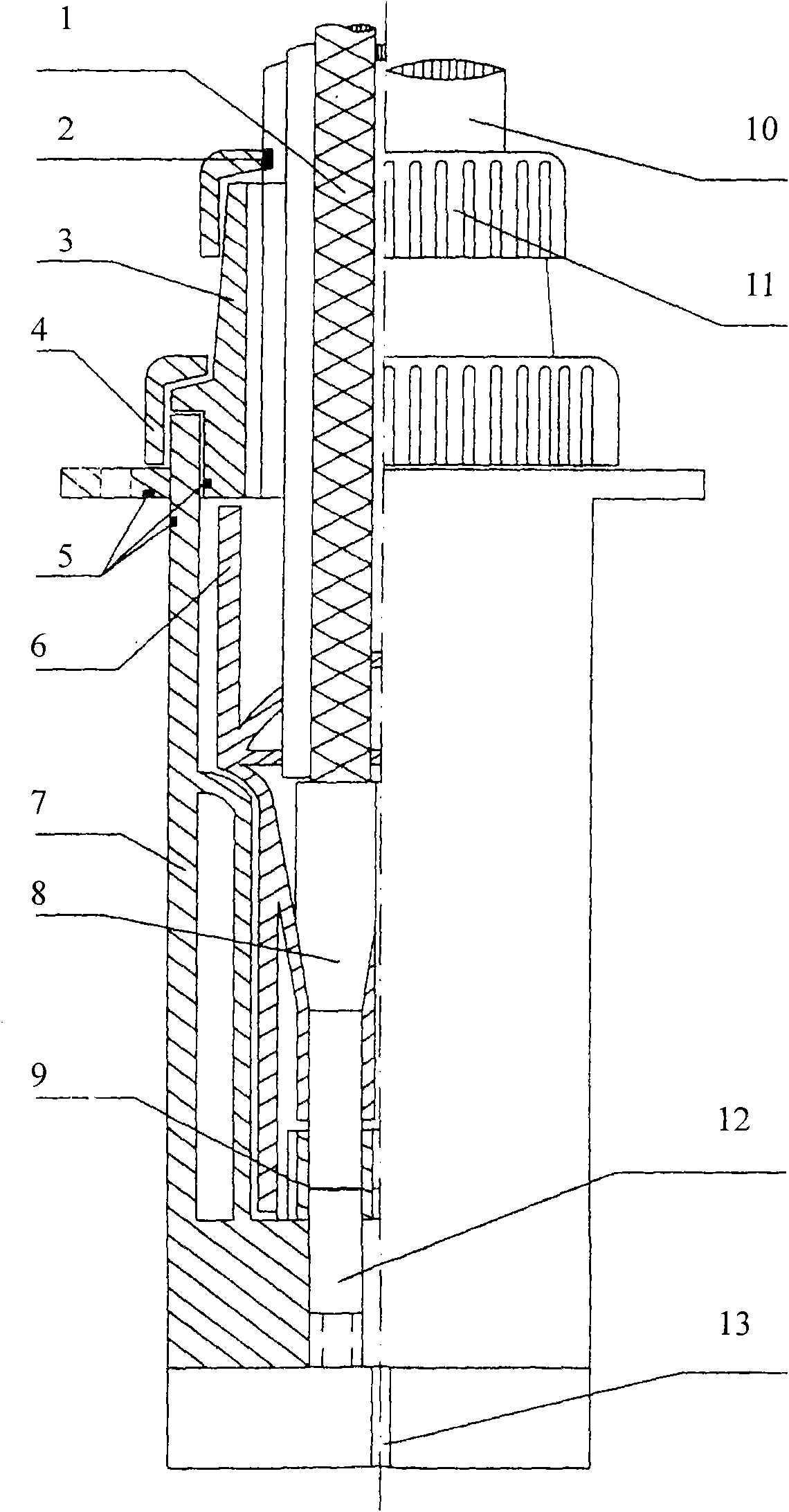

[0017] Such as figure 1 As shown, an improved underground transformer high-voltage cable connector of the present invention is composed of an insulating joint seat 7 and an insulating sealing cover 3, wherein the insulating joint seat 7 is cylindrical, and the upper end of the insulating joint seat 7 Opening, the lower end of the insulating joint seat 7 is closed, three high-voltage static contact through holes 13 are arranged in the lower end surface of the insulating joint seat 7, and a high-voltage static contact is arranged in any one of the high-voltage static contact through holes 13 Rod (not shown in the figure), the outer circumference of the insulating sealing cover 3 is provided with an annular protruding step, and the annular protruding step is arranged on the upper end surface of the insulating joint seat 7, and the annular protruding step The insulating sealing cover 3 below the step extends into the insulating joint seat 7, and the insulating sealing cover 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com