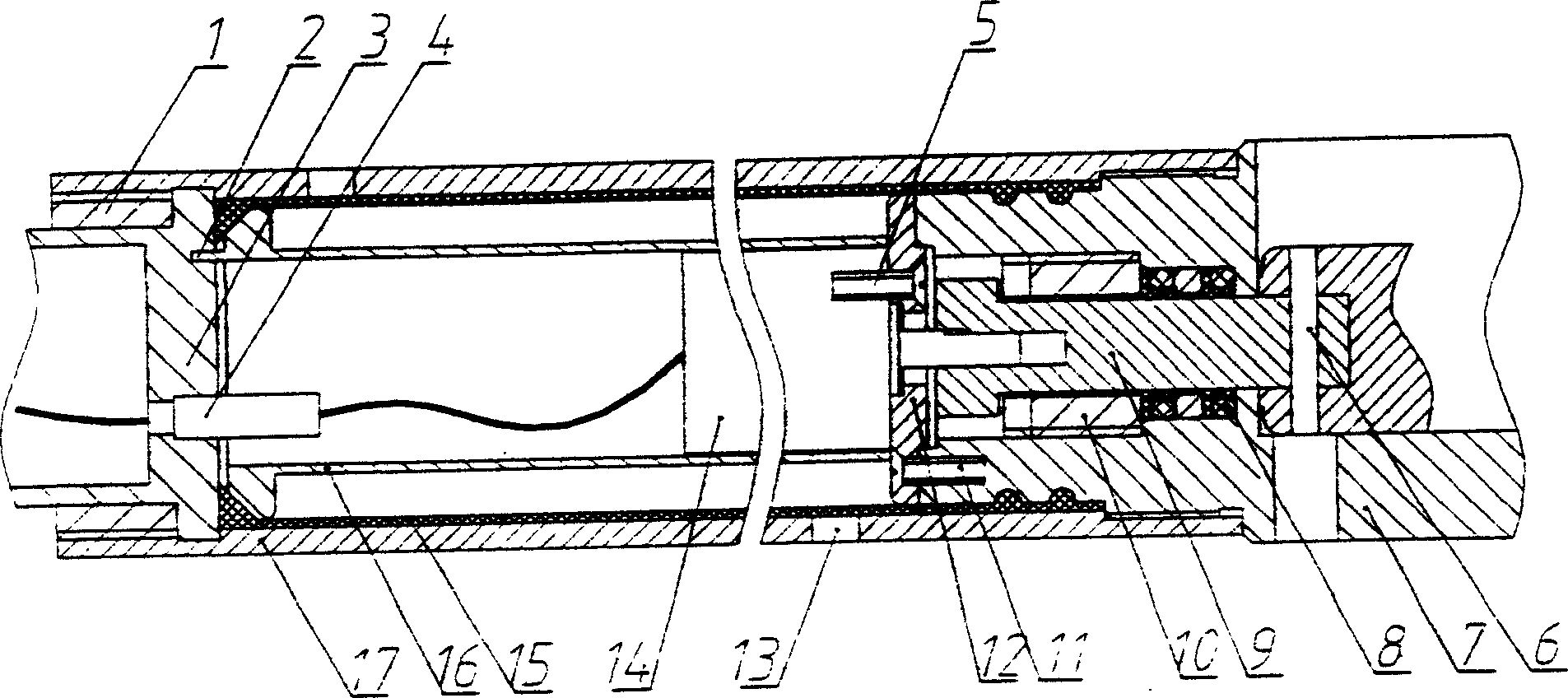

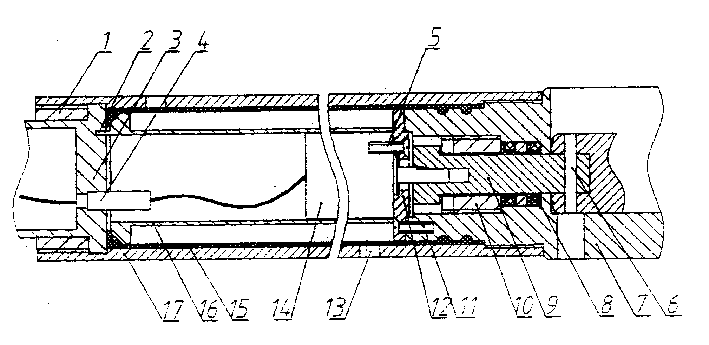

Sealed transmission method and device thereof

A technology of sealing transmission and flexible sealing, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as damage, affecting the normal operation of the motor, motor wear and damage, etc., to reduce difficulty, long working life, reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments of the present invention: the motor of the present invention can adopt servo motors, stepper motors or general AC or DC motor products sold on the market according to the needs of use, and its toothed slip ring type combined seal (8) can be sold on the market Assembled finished products, the sealing sleeve (15) can be made of oil-resistant rubber. During production, the motor is fixedly installed and soaked in a sealed container filled with insulating oil and has a flexible shell to run. The specific The production method is as follows: firstly, put the nut (10) and the tooth-shaped slip ring combined seal (8) on the adapter shaft (9); then, install the adapter shaft (9) on the connecting cylinder (7), And use the nut (10) to compress the toothed slip ring combined seal (8); fix the servo motor (14) on the mounting plate (12) with the screw (5), and then fix the mounting plate (12) with the screw ( 11) Fix it to the connecting cylinder (7). When installing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com