Welding protection device for semi-closed to-be-welded piece

A semi-closed, protective device technology, used in welding accessories, devices for supplying/removing protective gas, etc., which can solve the problems of uneven annular welds, valve body accuracy, poor use stability and cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

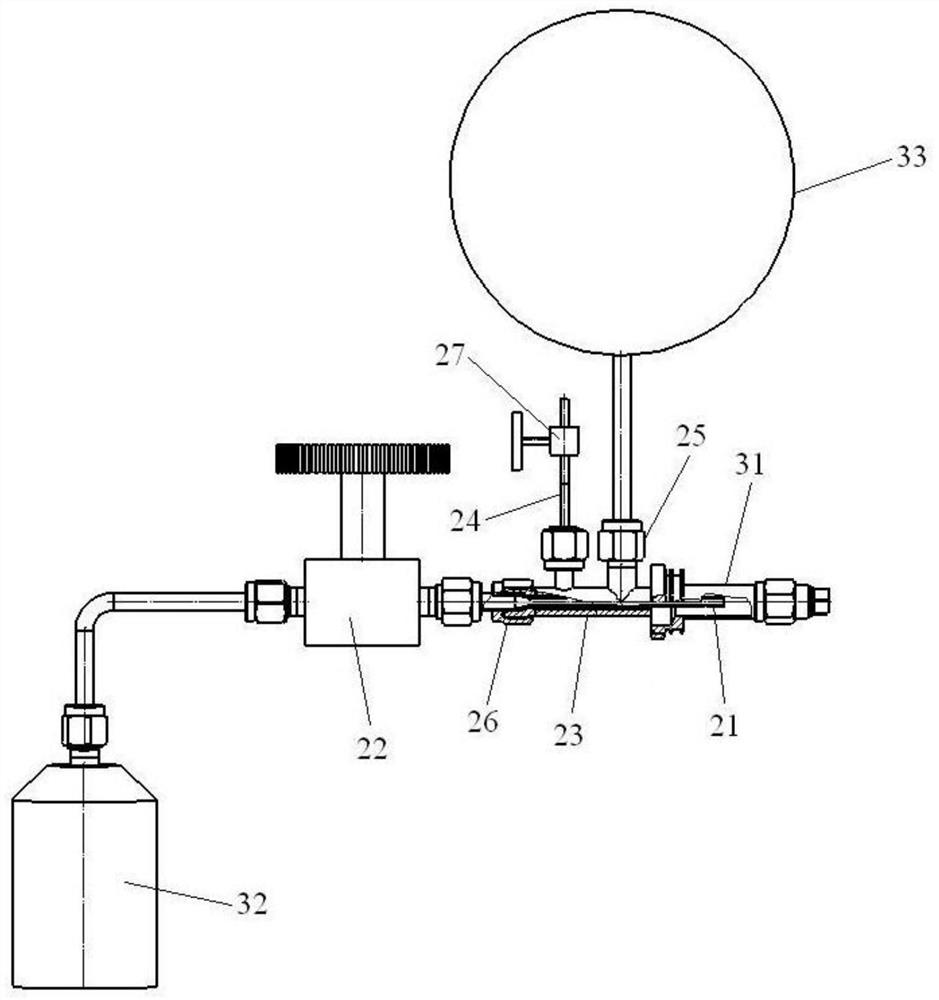

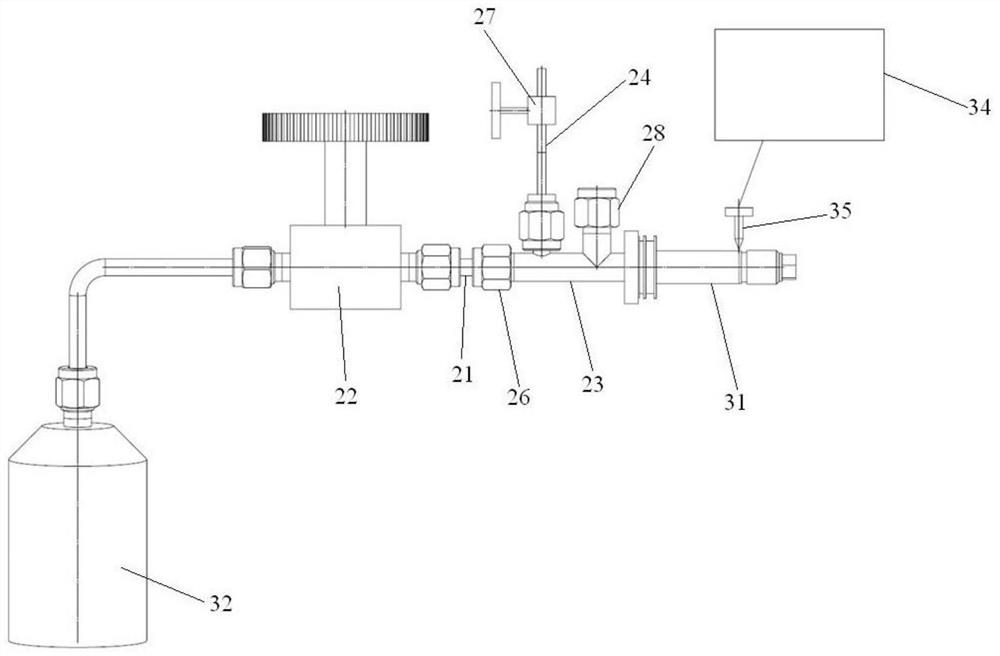

[0029] In order for those skilled in the art to better understand the technical solution of the present invention, the semi-enclosed welding protection device for parts to be welded provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

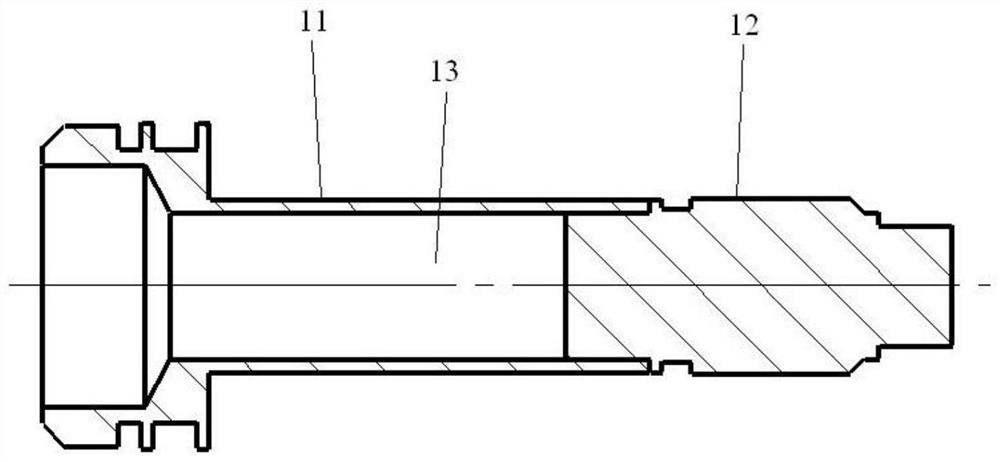

[0030] Such as figure 2 As shown, this embodiment provides a semi-enclosed welding protection device for the part 31 to be welded, including a gas delivery pipe 21, a first adjustment part 22 and a return pressure holding assembly, wherein one end of the gas delivery pipe 21 is passed through the first adjustment The component 22 communicates with the shielding gas source 32 for providing shielding gas, and the other end passes through the return pressure holding assembly, and extends into the semi-closed inner cavity of the semi-closed part 31 to be welded to deliver the shielding gas into the semi-closed interior cavity; the first regulating part 22 is used to adjust the flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com