Process for making gastroretentive dosage forms

A technology for gastric retention and dosage forms, applied in pharmaceutical formulations, pill delivery, drug delivery, etc., can solve problems such as inability to provide load rate, inapplicable active ingredients, and difficulty in implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

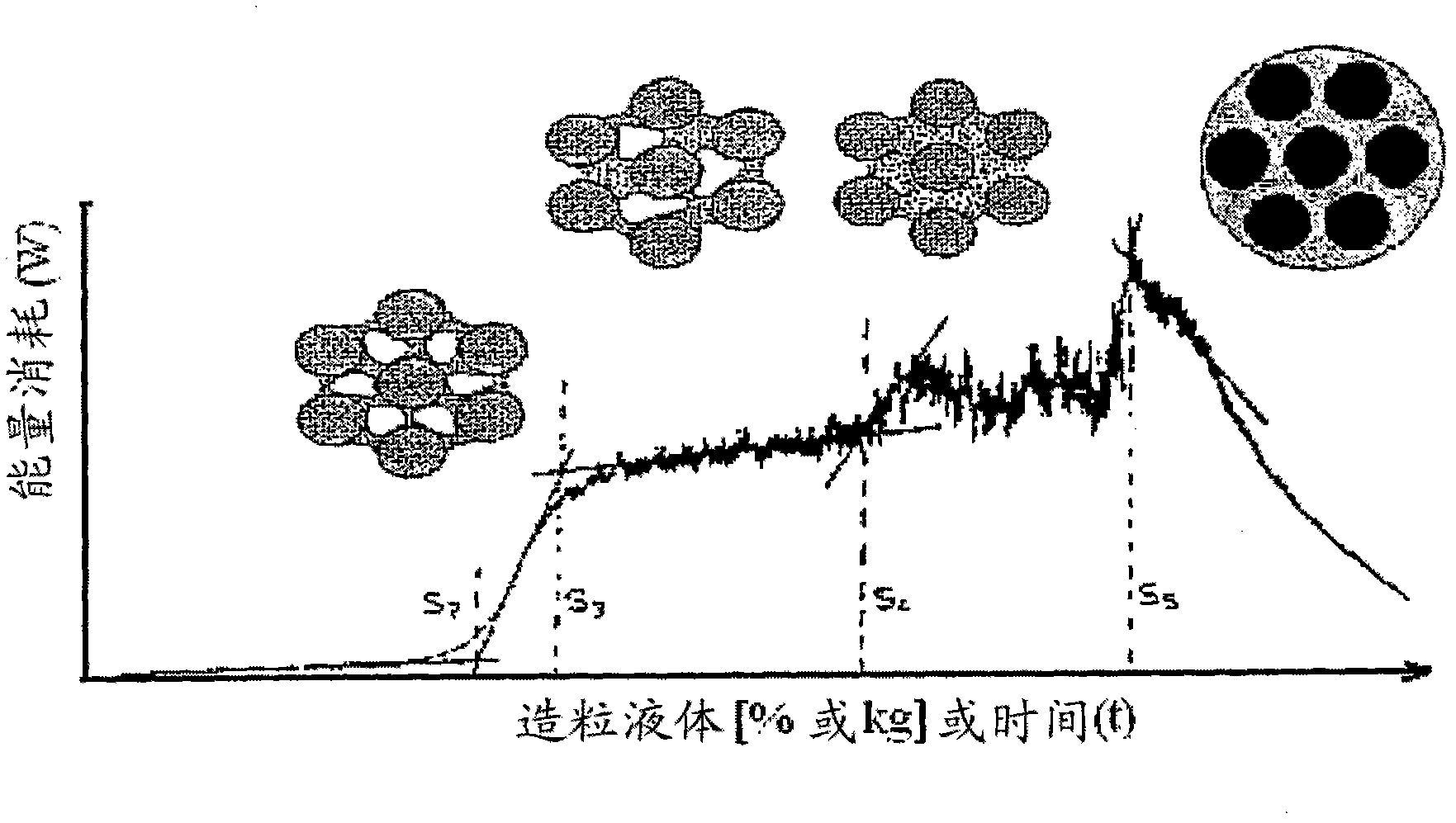

Method used

Image

Examples

Embodiment

[0119] Preparation of solid dosage form according to the invention

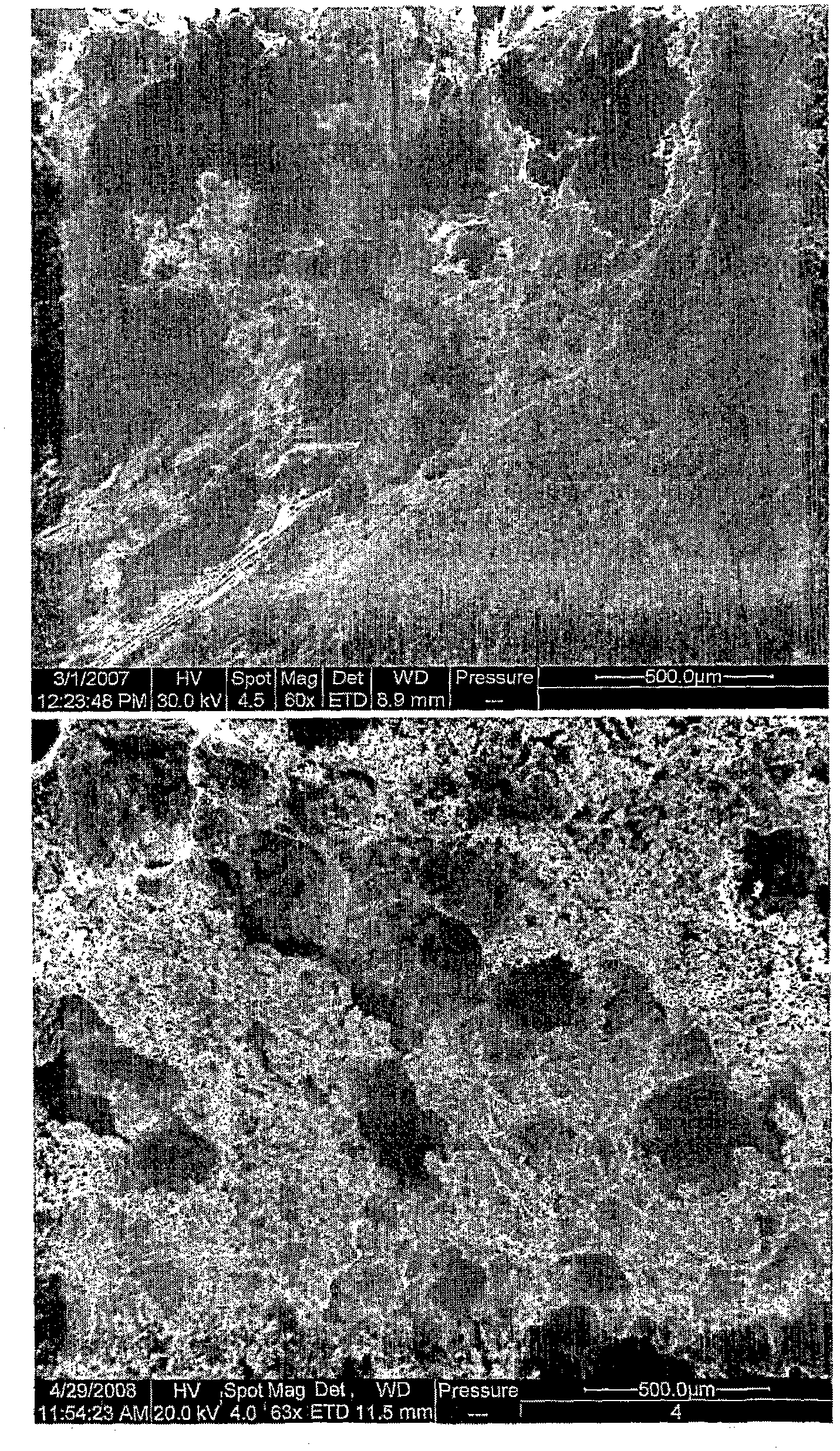

[0120] Two different solid dosage forms (100 g batches) of the following compositions were prepared according to the present invention. Dosage form No. 1 includes hydrophilic API, and dosage form No. 2 includes hydrophobic API. The enlarged pictures of the structure No. 1 and No. 2 dosage forms are in image 3 Given in.

[0121]

[0122]

77.5%

[0123] The API powder and other auxiliary materials are loaded in a shear mixer 4M8 granulator and mixed for 2 minutes and 30 seconds at 150 rpm. The granulation was initiated by adding water at a rate of 10 ml / min at 1000 rpm. Over granulation was reached after introducing 80 ml of water to form a solution: powder ratio of 0.8, and the resulting paste was further kneaded at 1500 rpm for 2 minutes and 30 seconds until it showed 4 to 8% torque resistance. The resulting material is then molded in a paraffin oil lubricated shell. The last drying step carried out was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com