Micro-scale six-roller mill with static stability

A six-high rolling mill, micro-scale technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of micro-scale instabilities, achieve the elimination of super large axial force, stable operation, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

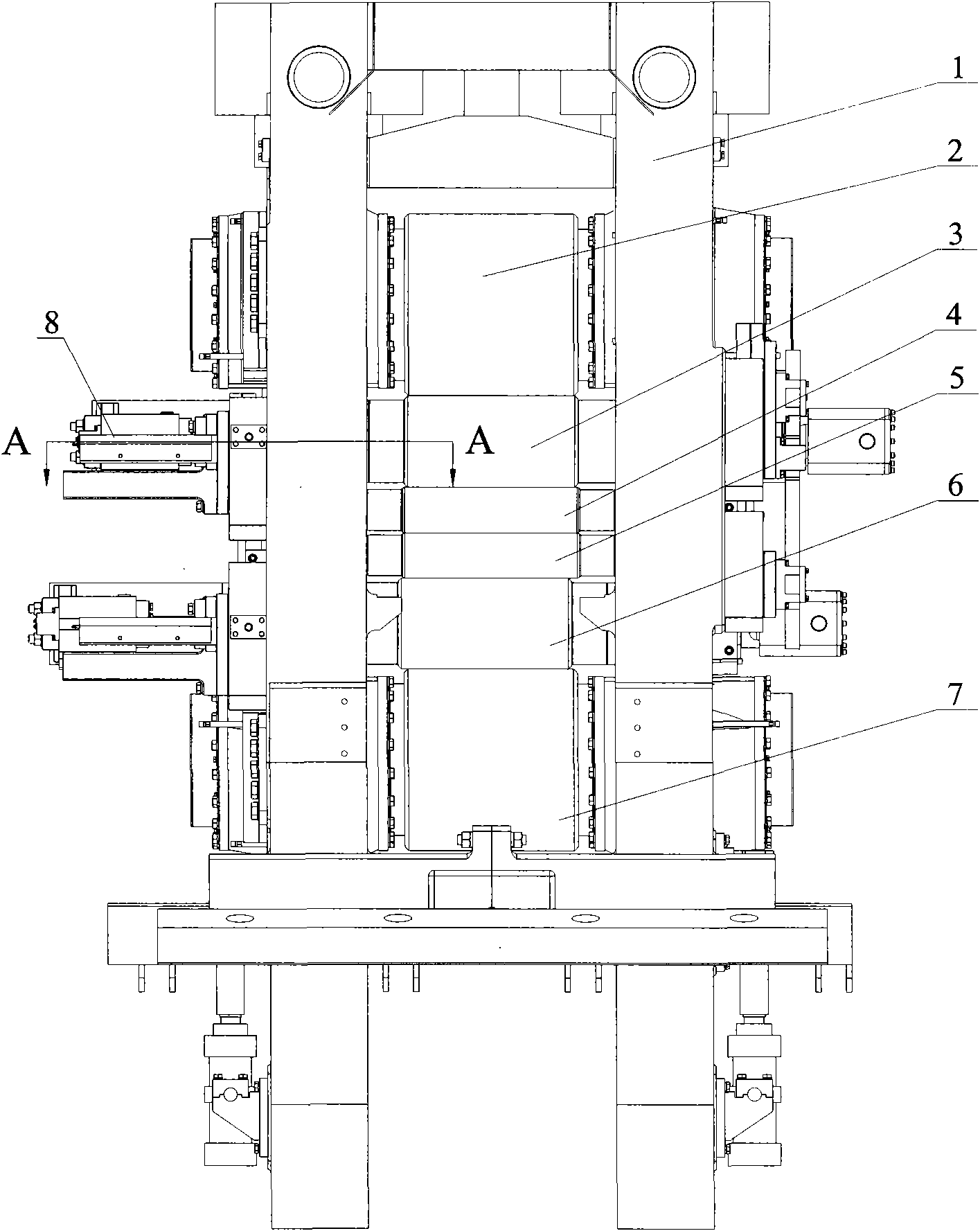

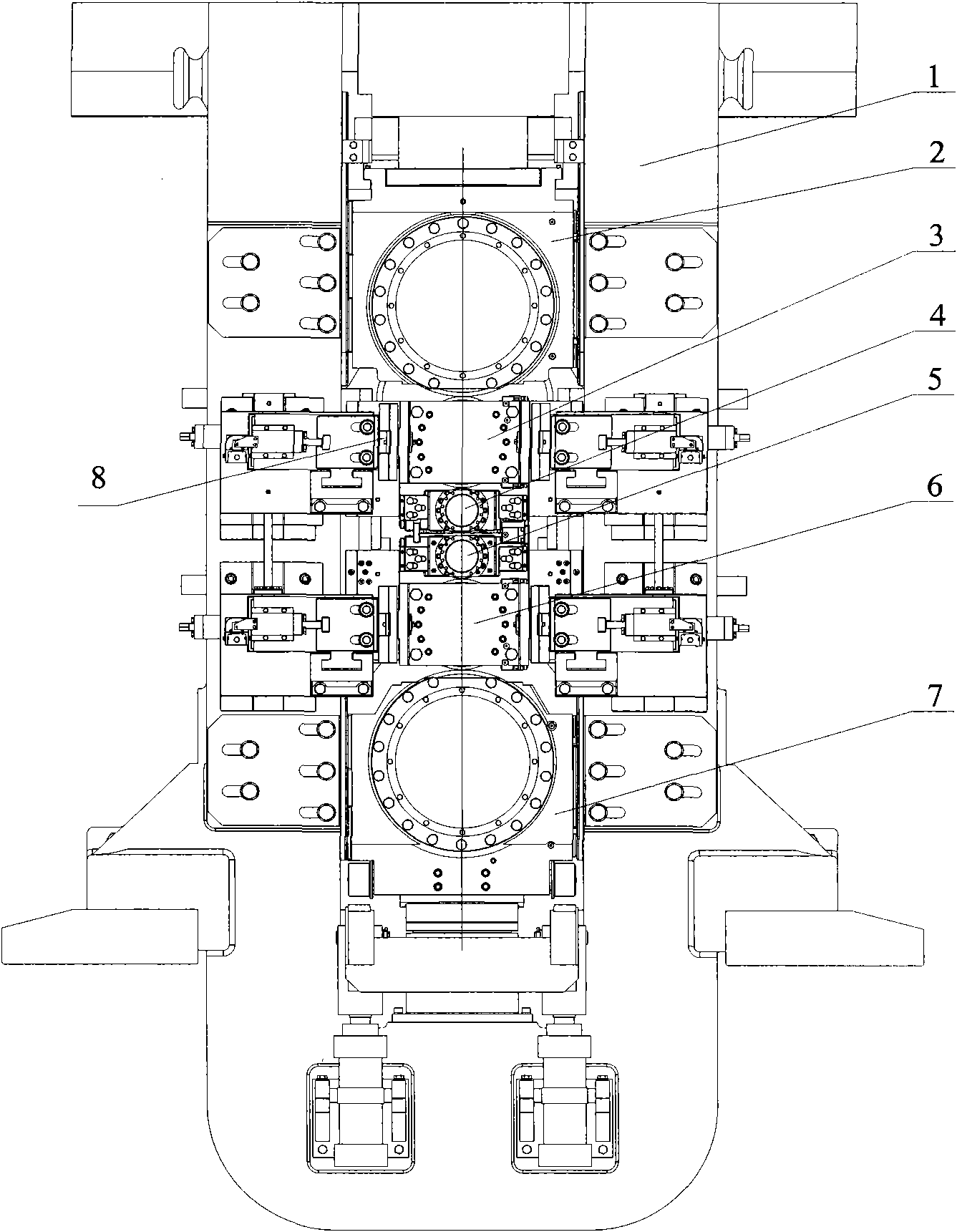

[0025] figure 1 It is a 650mm microscale static determinate six-high rolling mill disclosed by the present invention. The six-roll rolling mill includes a driving motor, a reducer, a gear stand and a frame 1, and the parallel positioning device of the six-roll rolling mill presses the four bearing seats of the upper and lower back-up rolls (2, 7) against the On the side slide plate 13 of the frame column, the eight bearing seats of the upper and lower intermediate rolls (3, 6) and the upper and lower work rolls (4, 5) are pressed against the intermediate roll bending device block 20 , the axes of the six rolls are located on the same vertical plane, that is, the offset distance between the six rolls is zero, that is, e=0.

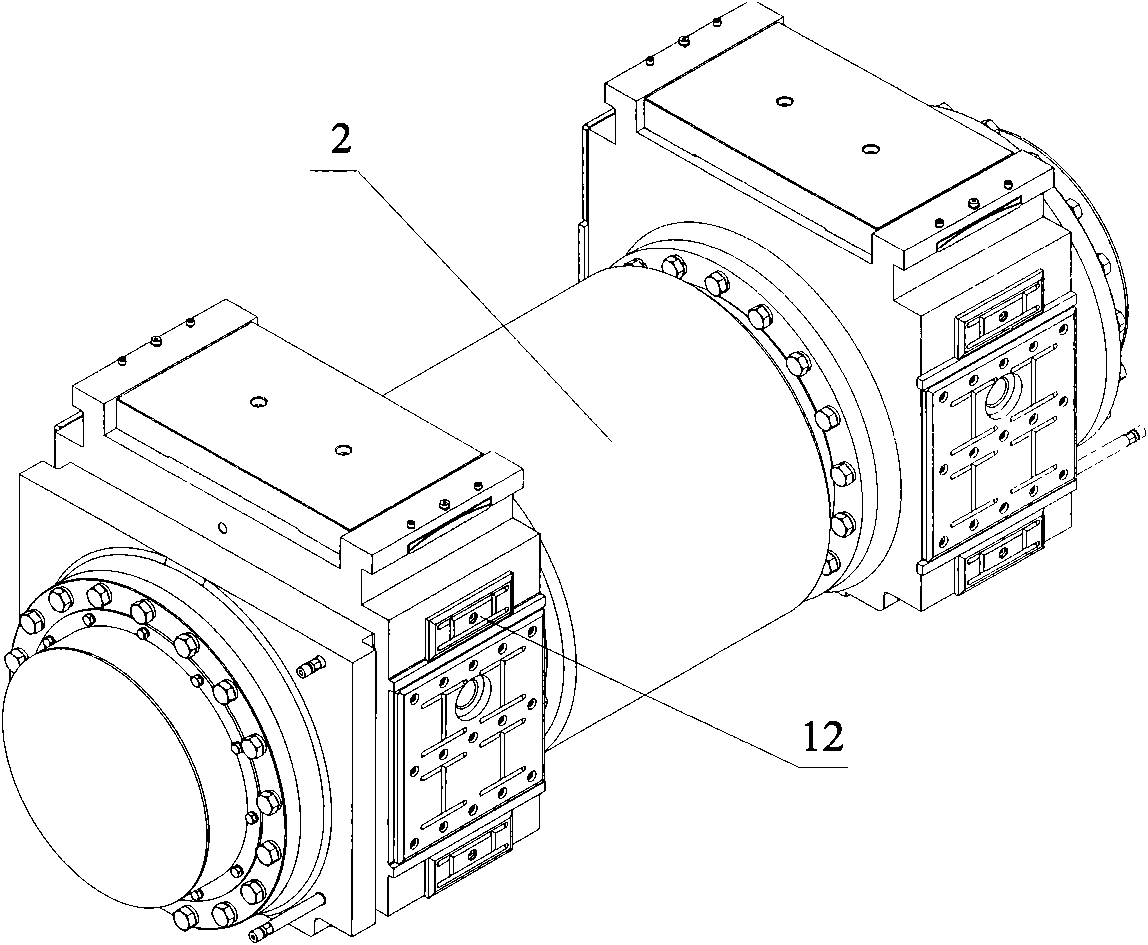

[0026] The structures of the parallel positioning devices of the upper and lower back-up roll systems (2, 7) are the same, wherein the back-up roll hydraulic cylinder I 10 and the back-up roll hydraulic cylinder II11 are respectively set on the upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com