Method for producing prevulcanization ring-shaped tire tread and vulcanization device therefor

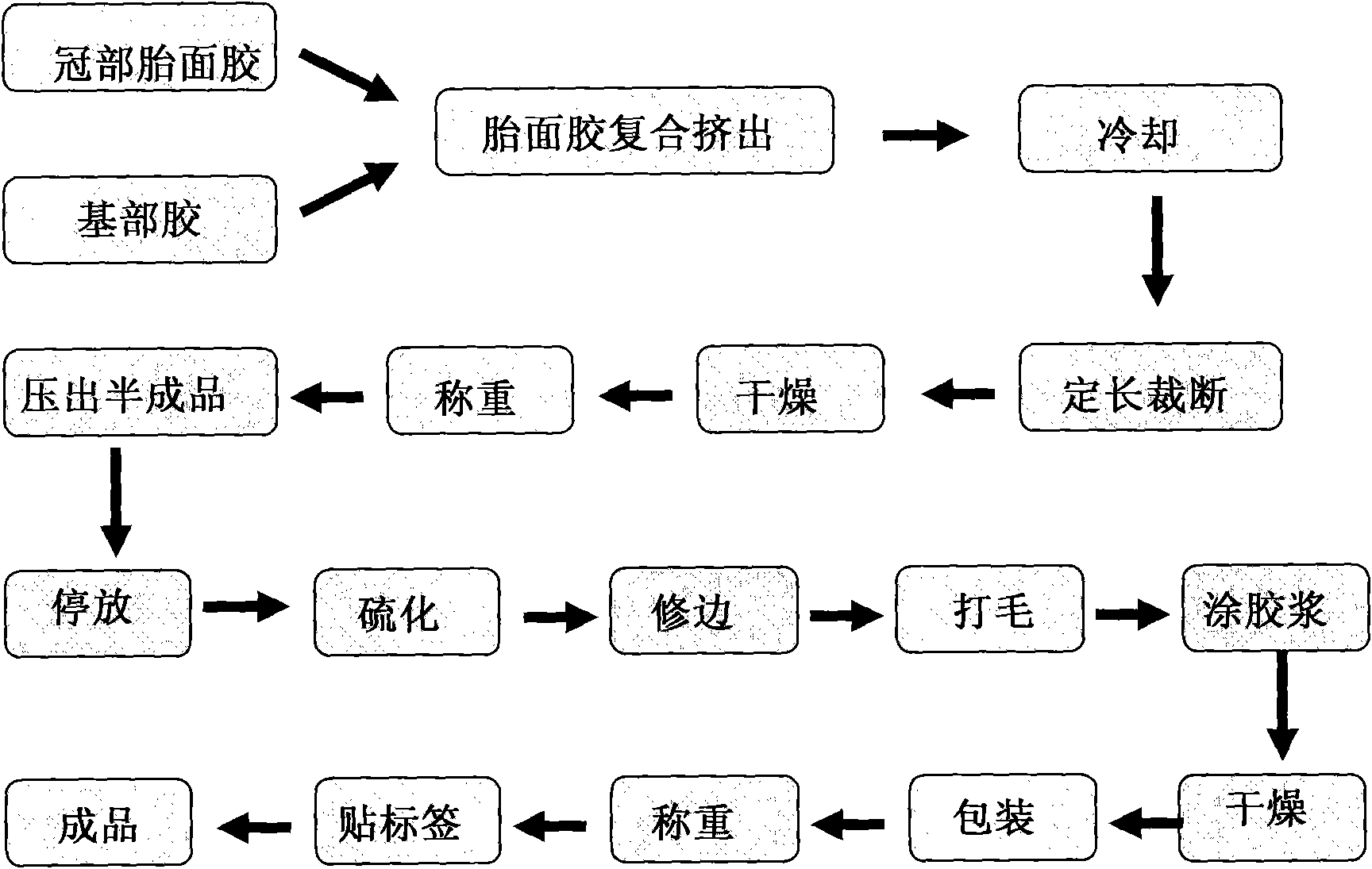

A pre-vulcanization, annular technology, applied in the field of rubber machinery, can solve the problems of complex control system and method, large equipment investment, low production efficiency, etc., and achieve the effect of reducing equipment investment and production cost, being widely used, and facilitating production scheduling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

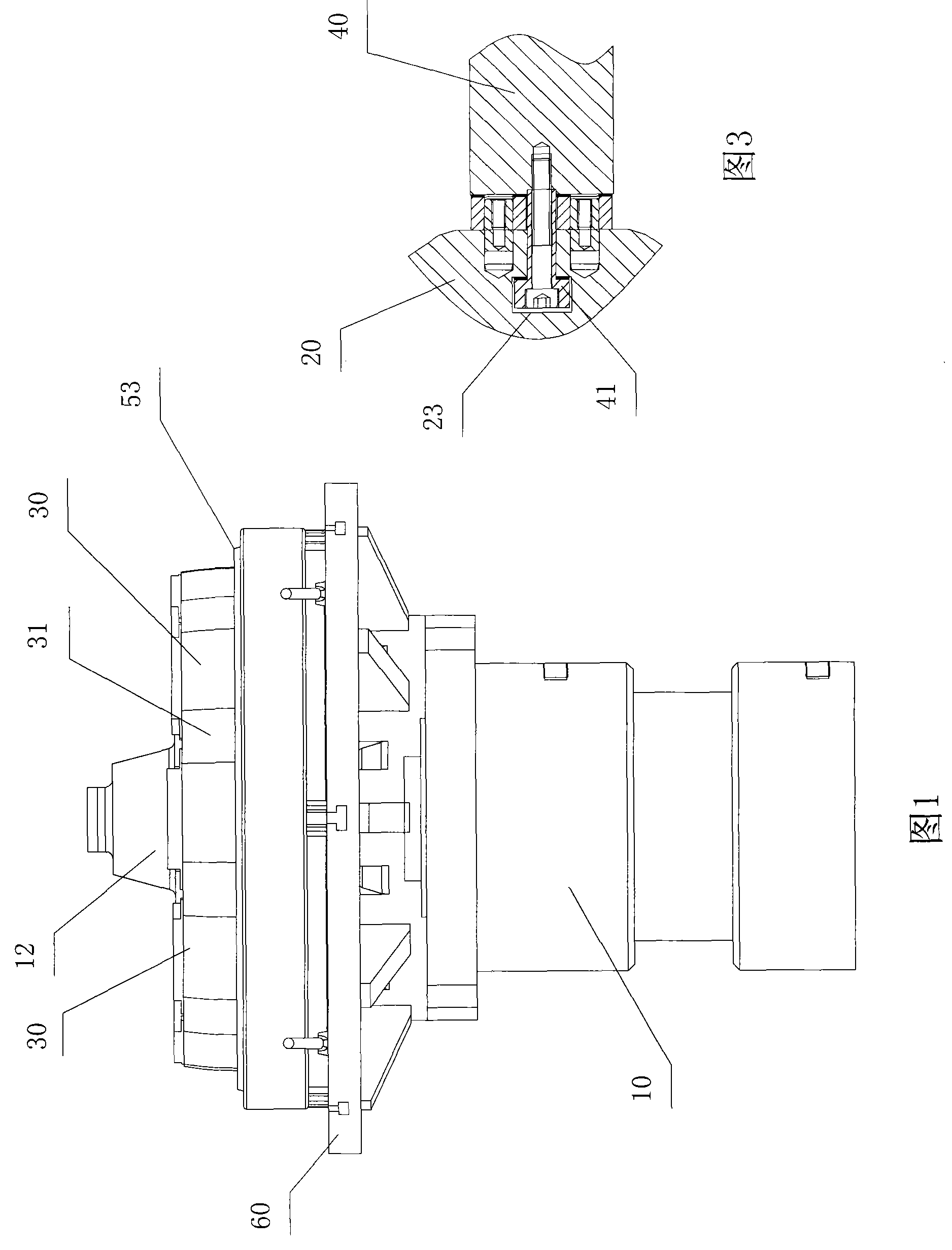

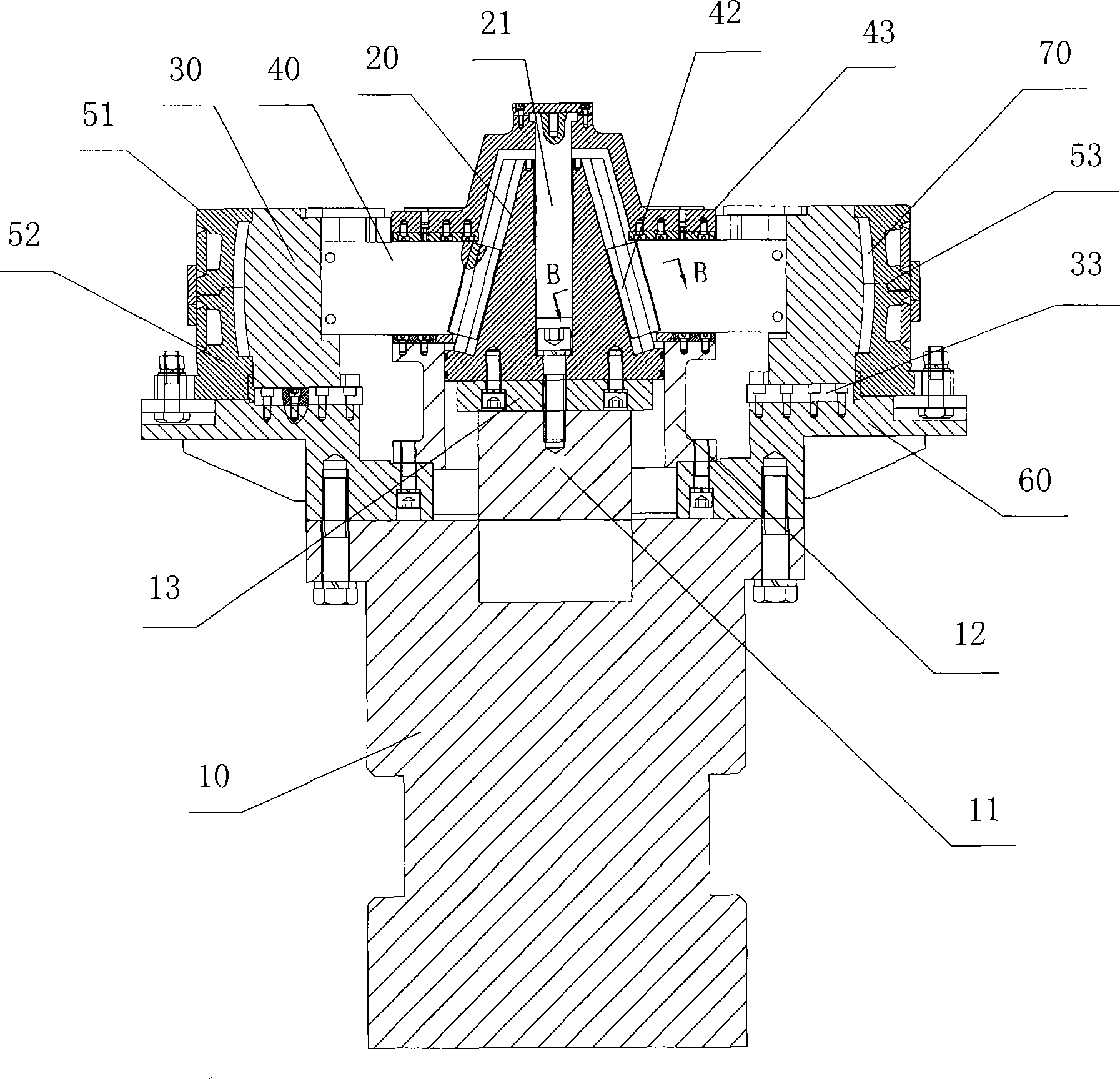

[0071] Example 1, such as Figure 1 to Figure 8 As shown, the vulcanization device used for retreading tires or manufacturing new tires for pre-vulcanization double-compound annular tread mainly includes an oil cylinder 10, a conical block 20, a movable core module 30, a support plate 40, a pattern mold 50 and a base 60. in,

[0072] The oil cylinder 10 is used to provide driving force to realize the pressure acting on the surface of the double-compound annular tread in the vulcanization process.

[0073] The conical block 20 driven by the oil cylinder 10 realizes vertical movement, and the conical block 20 drives the integral movable mandrel to retract inwardly or expand outwardly along the horizontal radial direction.

[0074] On the outer surface of the tapered block 20 , there are 10 sliding slots 23 symmetrically arranged with the same number as the movable core modules 30 . The T-shaped wear plate 41 at the end of the support plate 40 is nested in the slide groove 23 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com