Adjustable nut plate component for bodywork

A technology for adjusting nuts and plate components, applied to nuts, threaded fasteners, motor vehicles, etc., can solve problems such as small adjustment range, welding deformation, and positioning deviation of nut projection welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

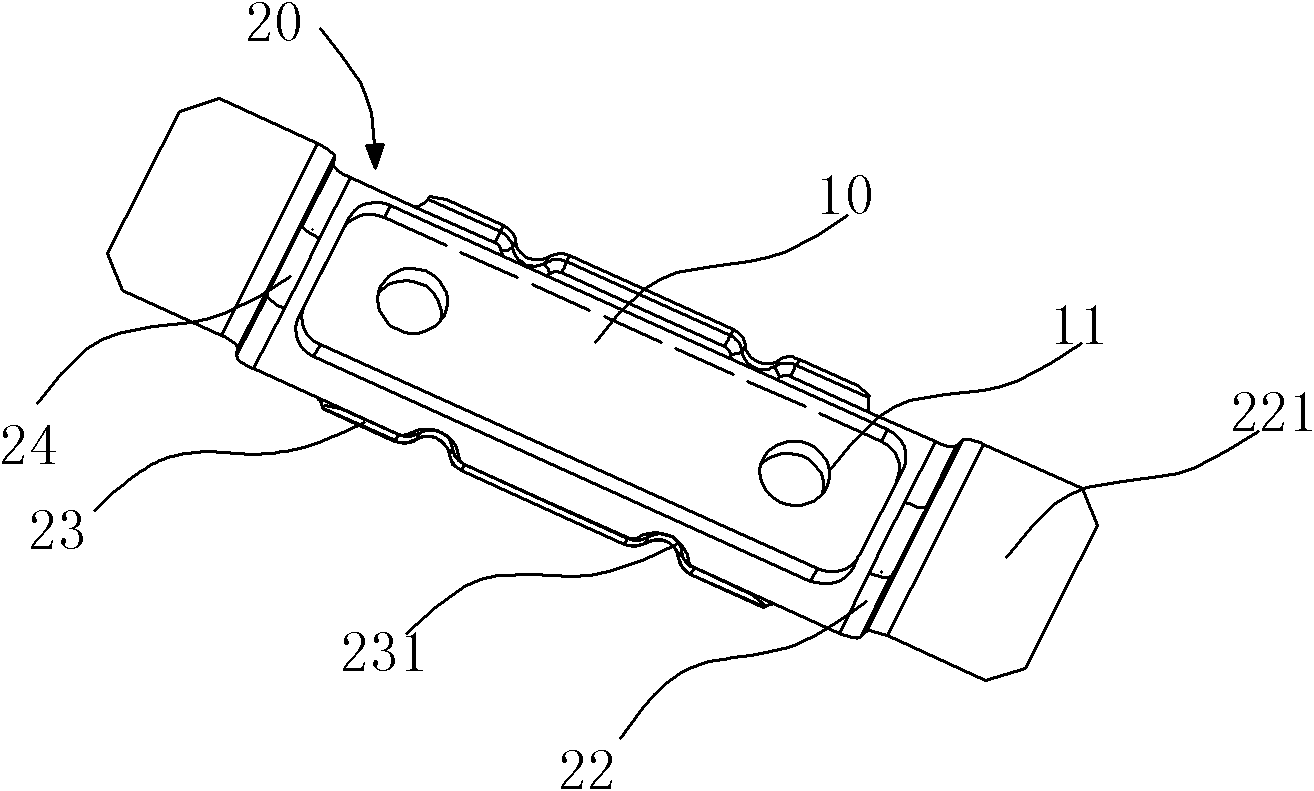

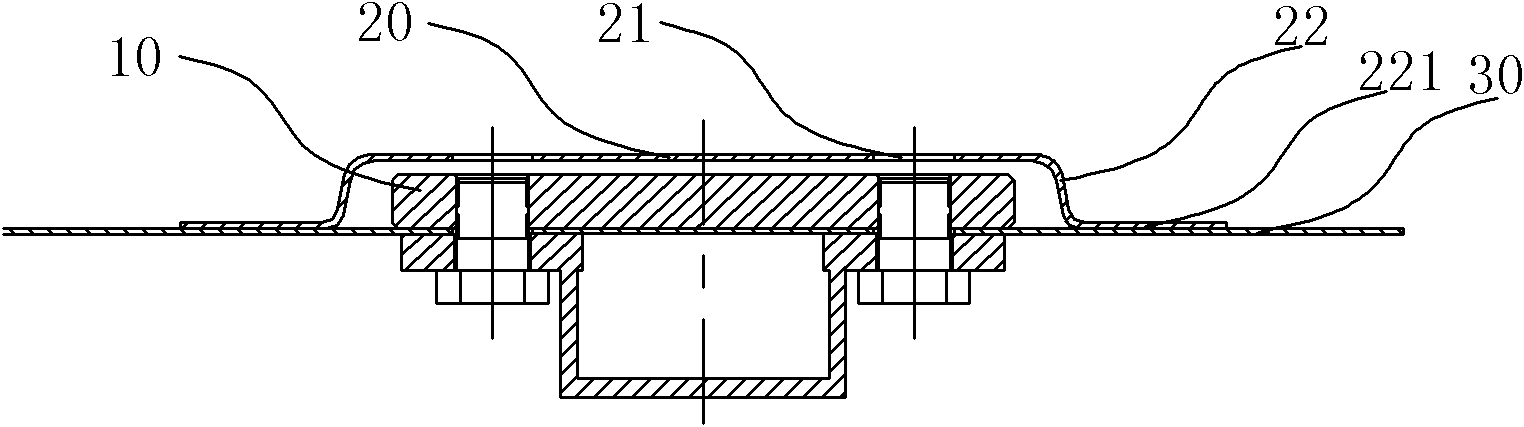

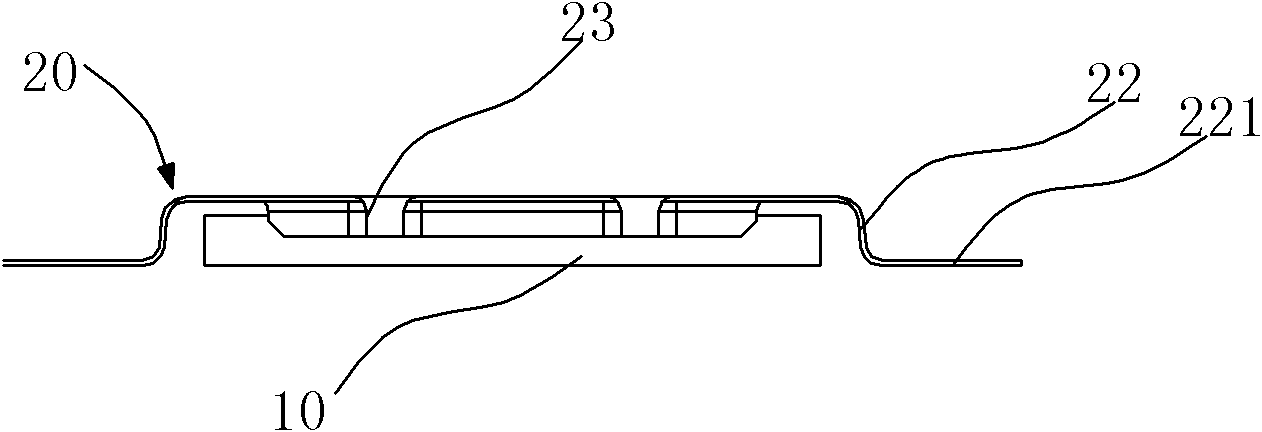

[0011] An adjustable nut plate assembly for a vehicle body includes a nut plate 10 provided with a threaded hole 11 , the nut plate 10 is set in a limiting device 20 , and the limiting device 20 is set on a vehicle body 30 . The effect of stop device 20 is exactly to limit the position of nut plate 10, guarantees that the plate surface of nut plate 10 fits with car body, and the lock hook on the car body 30 adopts bolt connection with the threaded hole 11 on the nut plate 10, and car body The aperture of the mounting hole of the mounting position on the 30 is greater than the diameter of the bolt and the aperture of the threaded hole on the nut plate 10, and the position of the nut plate 10 is adjusted by fine-tuning the position of the bolt in the mounting hole on the car body 30, so that it can be Appropriate adjustment in the bit device 20 to achieve the best installation effect.

[0012] The limiting device 20 is in the shape of an open box, the nut plate 10 is located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com