Mobile armrest inspection device of passenger conveyer

A passenger conveyor and inspection device technology, which is applied in escalators, transportation and packaging, etc., can solve the problems that the joints of the tensile body are not considered, it is difficult to quantitatively evaluate the abnormality of the tensile body, and the abnormality of the joints cannot be fully inspected. , to achieve the effect of improving the accuracy of anomaly detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

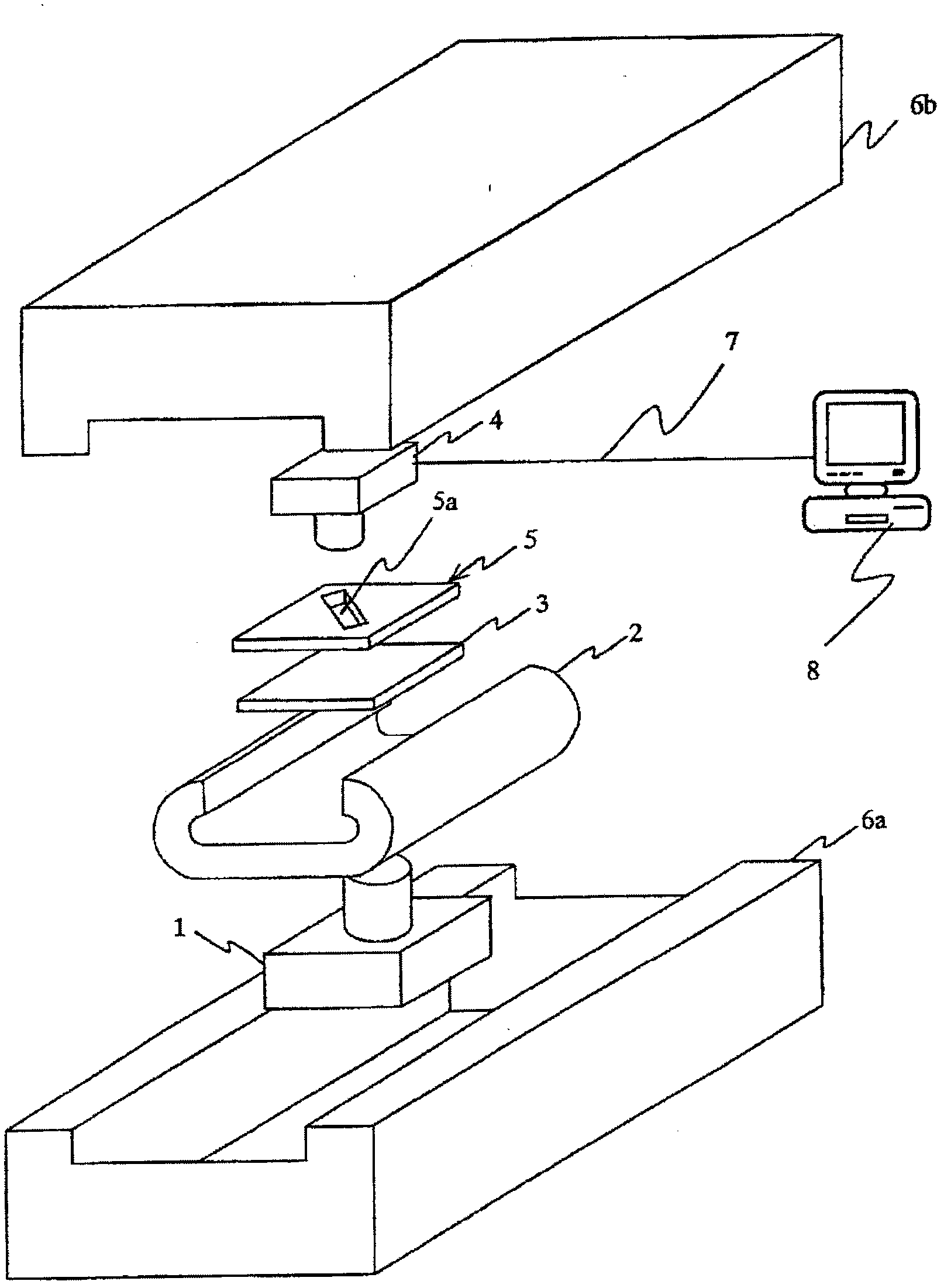

[0032] Such as figure 1 As shown, the first embodiment of the moving handrail inspection device of the passenger conveyor of the present invention has: an X-ray irradiator 1 that irradiates X-rays to the moving handrail 2 connected in a ring; The photoreceptor 3 of the X-ray that moves armrest 2; The amount of the X-ray that this photoreceiver 3 accepts is detected as the image acquisition device such as video camera 4; Be connected with this video camera 4 by signal line 7, to by video camera 4. An image processor 8 that analyzes the obtained image to detect whether there is any abnormality in the tensile body described later embedded in the moving handrail 2.

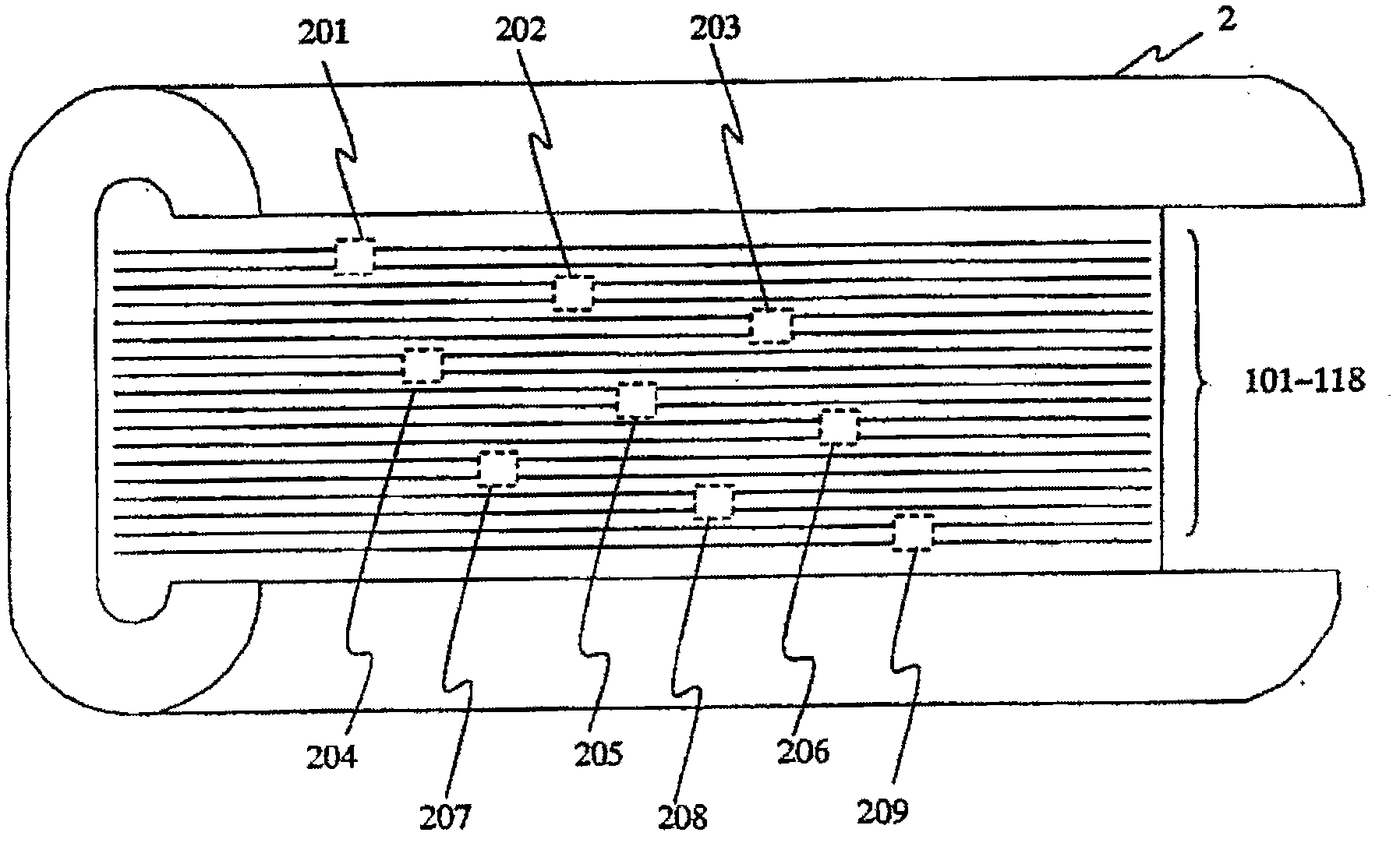

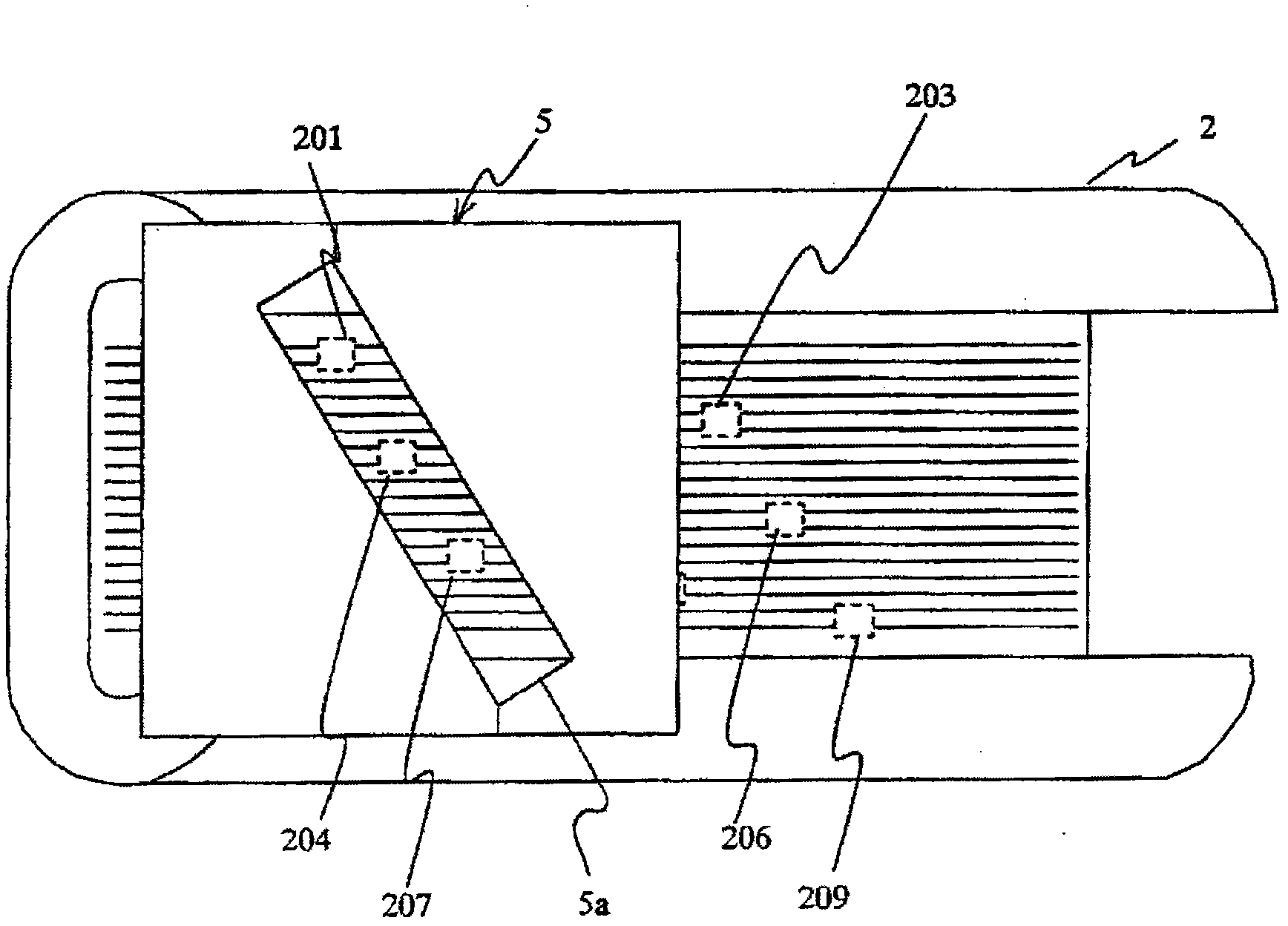

[0033] Such as figure 2 As shown, the moving handrail 2 has a plurality of tensile bodies inside, for example, 18 tensile bodies. The pull bodies are composed of steel wires (Still Code) 101-118, respectively. Additionally, if figure 1 , image 3 As shown, in the first embodiment of the present invention, there ...

no. 2 approach

[0054] Figure 9 It is a figure which shows the structure of the main part of the moving handrail with which the 2nd embodiment of the moving handrail inspection apparatus of the passenger conveyor of this invention is equipped, Figure 10 yes means figure 1 An image of the joint state of the steel wire according to the second embodiment is shown in the image processed by the image processor.

[0055] Such as Figure 9 As shown, the difference between the second embodiment of the present invention and the above-mentioned first embodiment is that in the first embodiment, the steel wires 101-118 form a ring along with the moving handrail 2, and the joints are configured such that 201-209 have gaps. In the second embodiment, the joints 301 to 309 are configured in an overlapping structure. Other structures are the same as those of the first embodiment.

[0056] In this case, the image processor 8, such as Figure 8 As shown, in the case where the light quantity P obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com