Porous nano hydrated titanium dioxide dearsenifying material and preparation method thereof

A hydrated titanium dioxide, nanotechnology, applied in the direction of titanium dioxide, nanostructure manufacturing, titanium oxide/hydroxide, etc., can solve the problems of low arsenic removal performance and poor separability performance of nano titanium dioxide, and achieve high arsenic removal performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

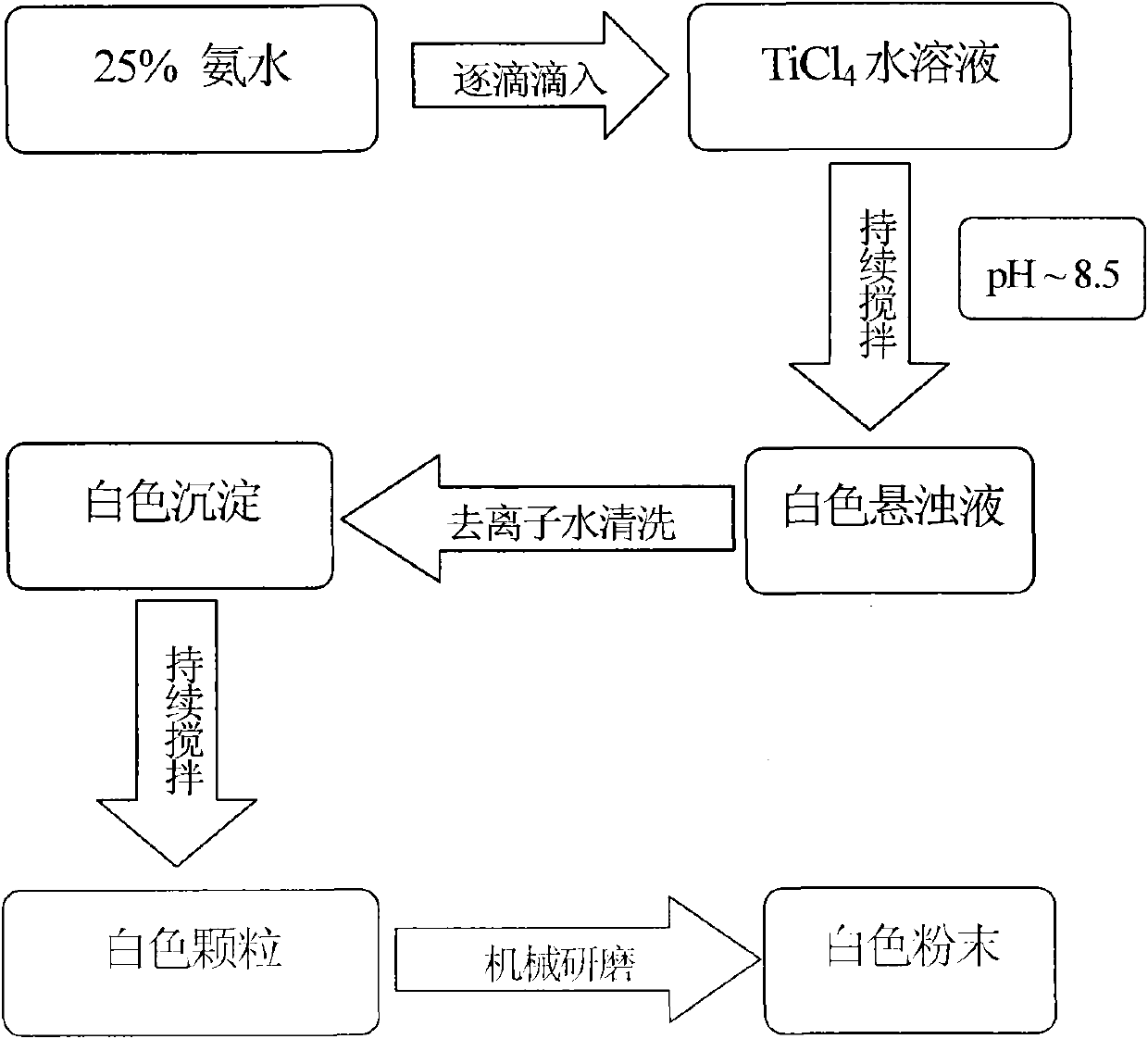

[0020] Such as figure 1 As shown, the preparation process of the porous nano hydrated titanium dioxide arsenic removal material of the present invention is as follows:

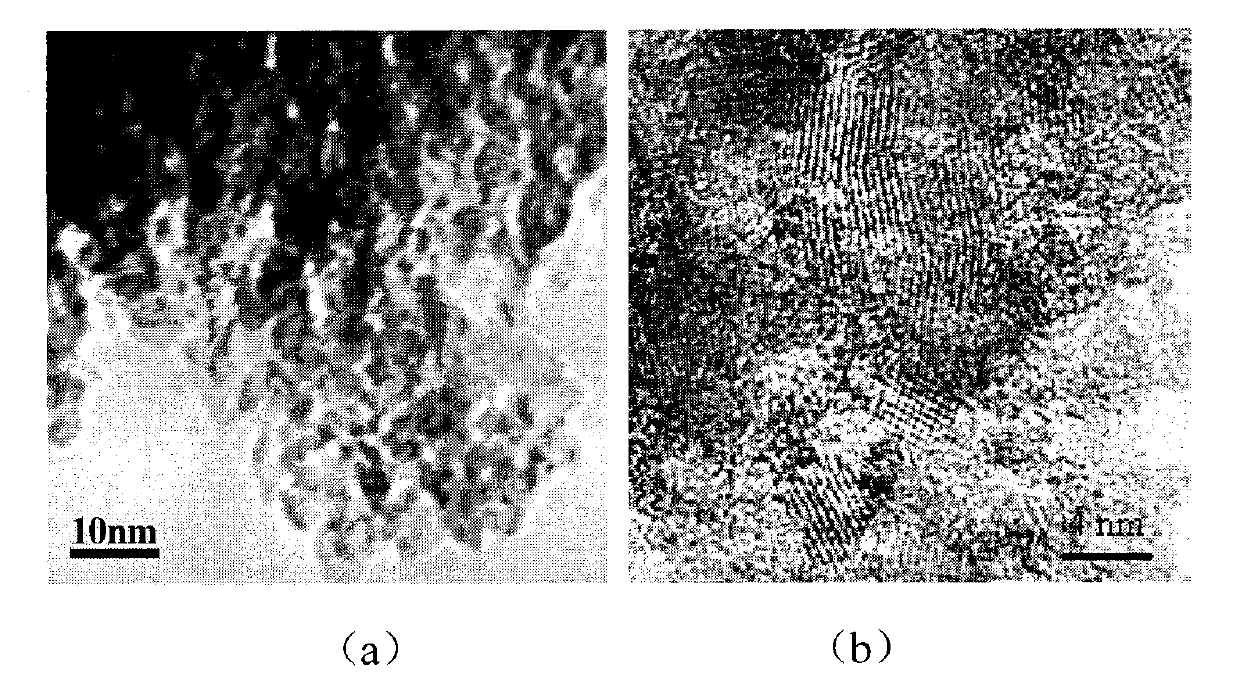

[0021] The titanium tetrachloride solution with a concentration of 0.1 mol / L was continuously stirred at 90°C, and then the ammonia solution with a mass fraction of 25% was evenly added dropwise to the titanium tetrachloride aqueous solution to obtain a white suspension. When the pH of the suspension reaches 8.5, stop adding ammonia water dropwise. Filter the white precipitate, wash it to neutral, and then dry it at 100°C until the mass fraction of water is about 12.5%, to obtain a large particle hydrated titanium dioxide with a certain strength, and grind it mechanically for 10 minutes to obtain a porous nano-hydrated titanium dioxide arsenic removal material It is composed of anatase-type and amorphous nano-hydrated titanium dioxide, wherein the mass fraction of anatase is 62.9%, and the mass fraction of wa...

Embodiment 2

[0030] Such as figure 1 As shown, the preparation process of the porous nano hydrated titanium dioxide arsenic removal material of the present invention is as follows:

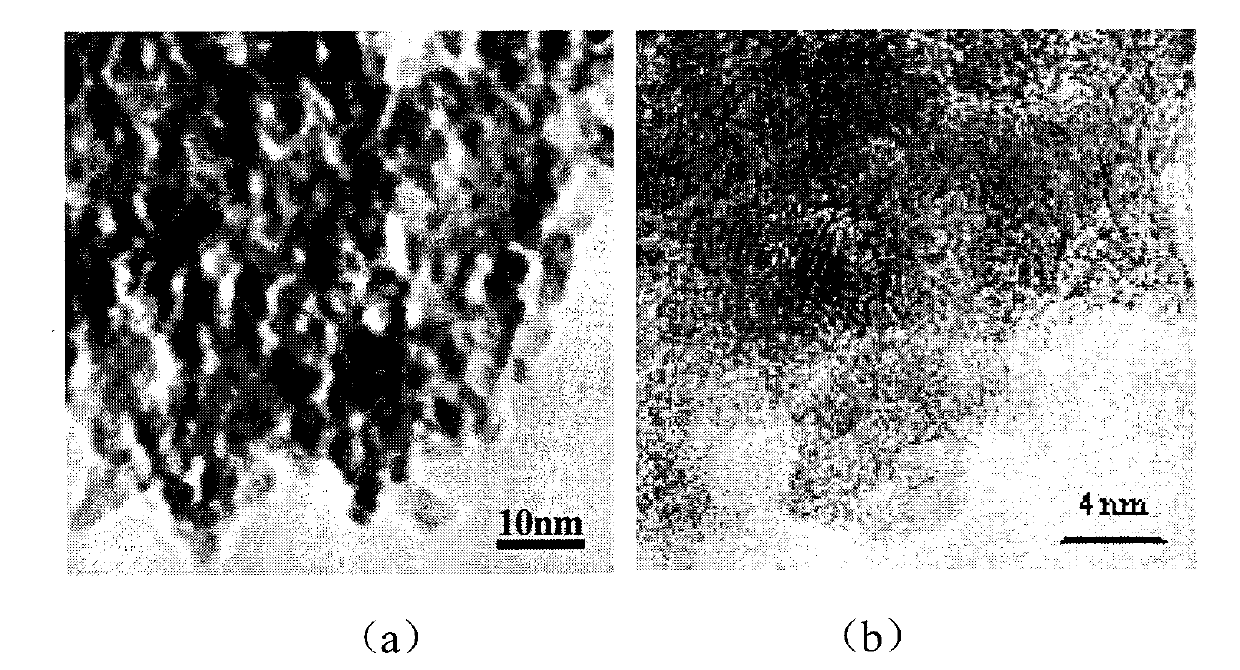

[0031] The titanium tetrachloride solution with a concentration of 0.1 mol / L was continuously stirred at 20° C., and then the ammonia solution with a mass fraction of 25% was evenly added dropwise into the titanium tetrachloride aqueous solution to obtain a white suspension. When the pH of the suspension reaches 8.5, stop adding ammonia water dropwise. Filter the white precipitate, wash it to neutral, and then dry it at 100°C until the mass fraction of water is about 19.8%, to obtain a large particle hydrated titanium dioxide with a certain strength, and grind it mechanically for 10 minutes to obtain a porous nano-hydrated titanium dioxide arsenic removal material It is composed of anatase and amorphous nano-hydrated titanium dioxide, wherein the mass fraction of anatase is 12.2%, and the mass fraction of wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com