Backlight module

A backlight module and optical coupling technology, applied in the field of backlight technology, can solve the problems of increasing the overall cost of the backlight module and assembly complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the description of the present invention more detailed and complete, reference may be made to the attached drawings and various embodiments described below, and the same numbers in the drawings represent the same or similar elements. On the other hand, well-known elements and steps have not been described in the embodiments in order to avoid unnecessarily limiting the invention.

[0033] As used herein, "about," "approximately," or "approximately" is used to modify any quantity that may vary slightly, but which does not alter its essence. Unless otherwise specified in the embodiments, it means that the error range of the numerical value modified by "about", "approximately" or "approximately" is generally allowed within 20%, preferably within 10%. Within, and more preferably within five percent.

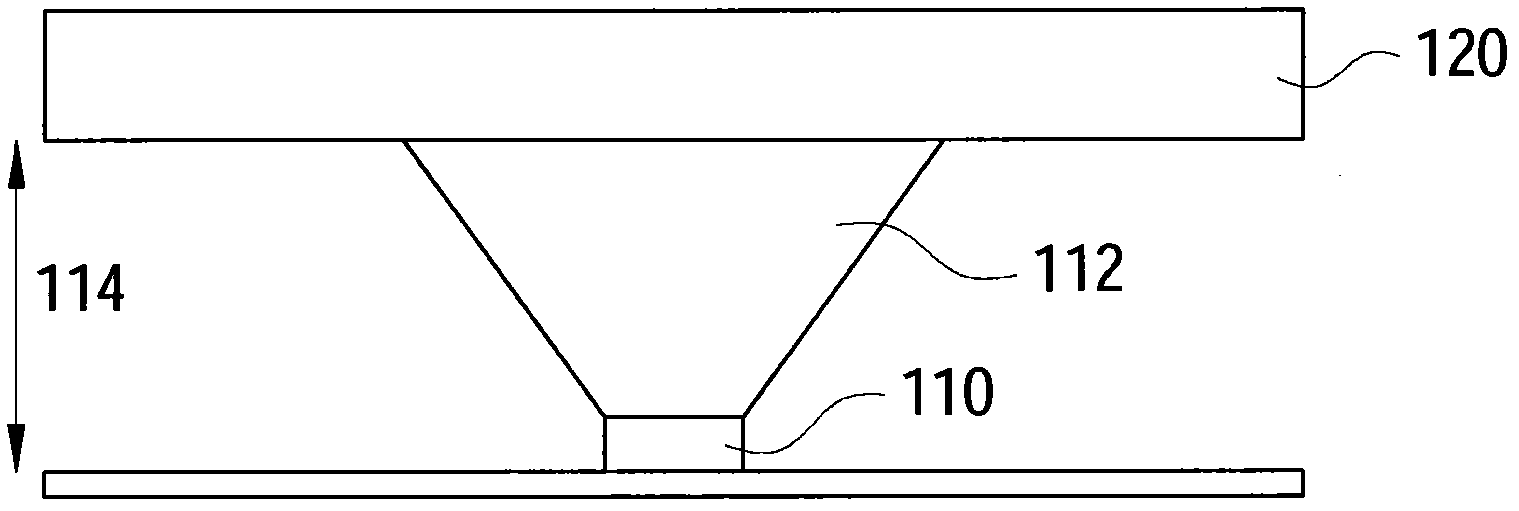

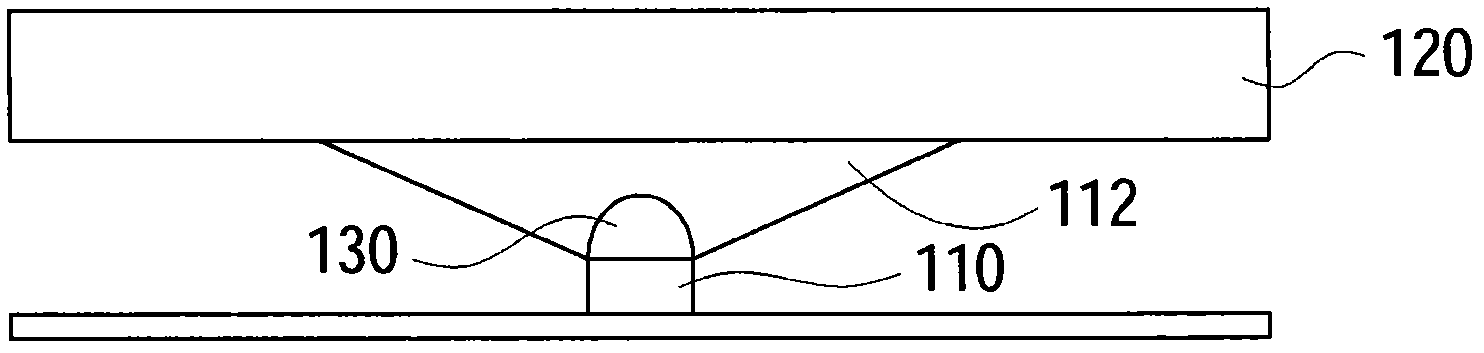

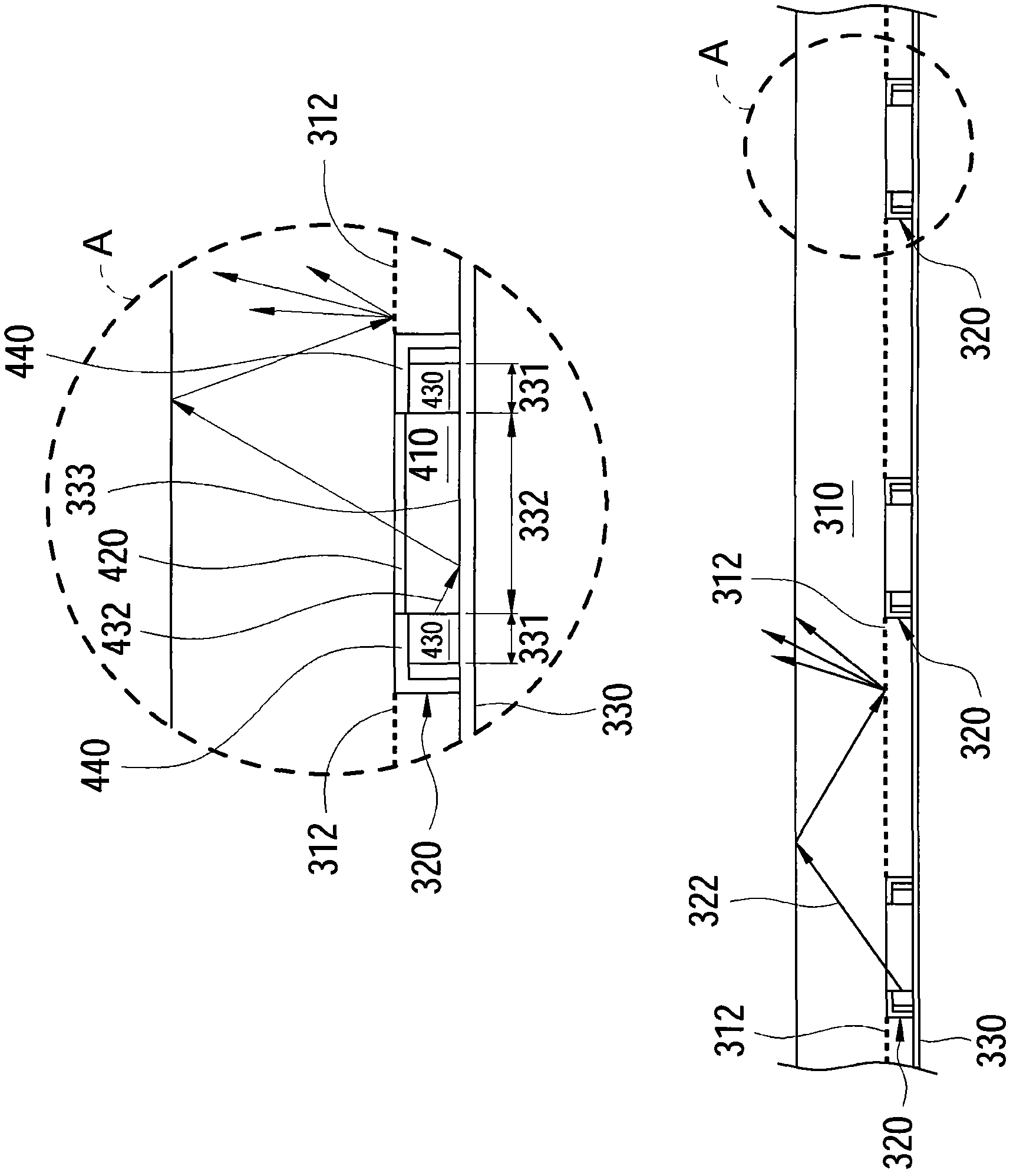

[0034] refer to image 3 , image 3 It is a sectional view and a partially enlarged view of a backlight module according to an embodiment of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com