Sensor for testing characteristic of high-voltage switch

A high-voltage switch and sensor technology, applied in circuit breaker testing, instruments, measuring devices, etc., can solve problems such as inconsistent testing standards, cumbersome operations, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

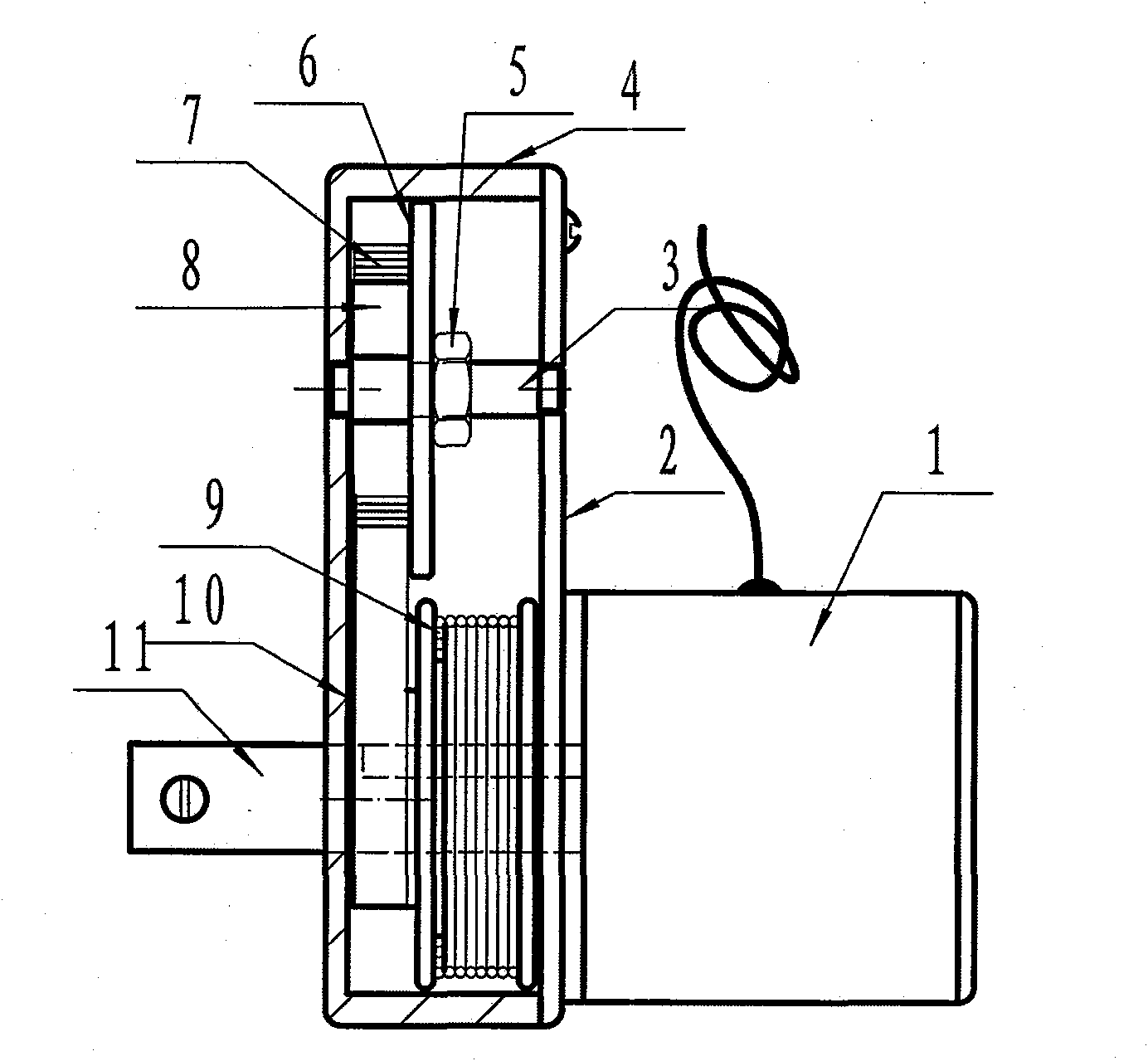

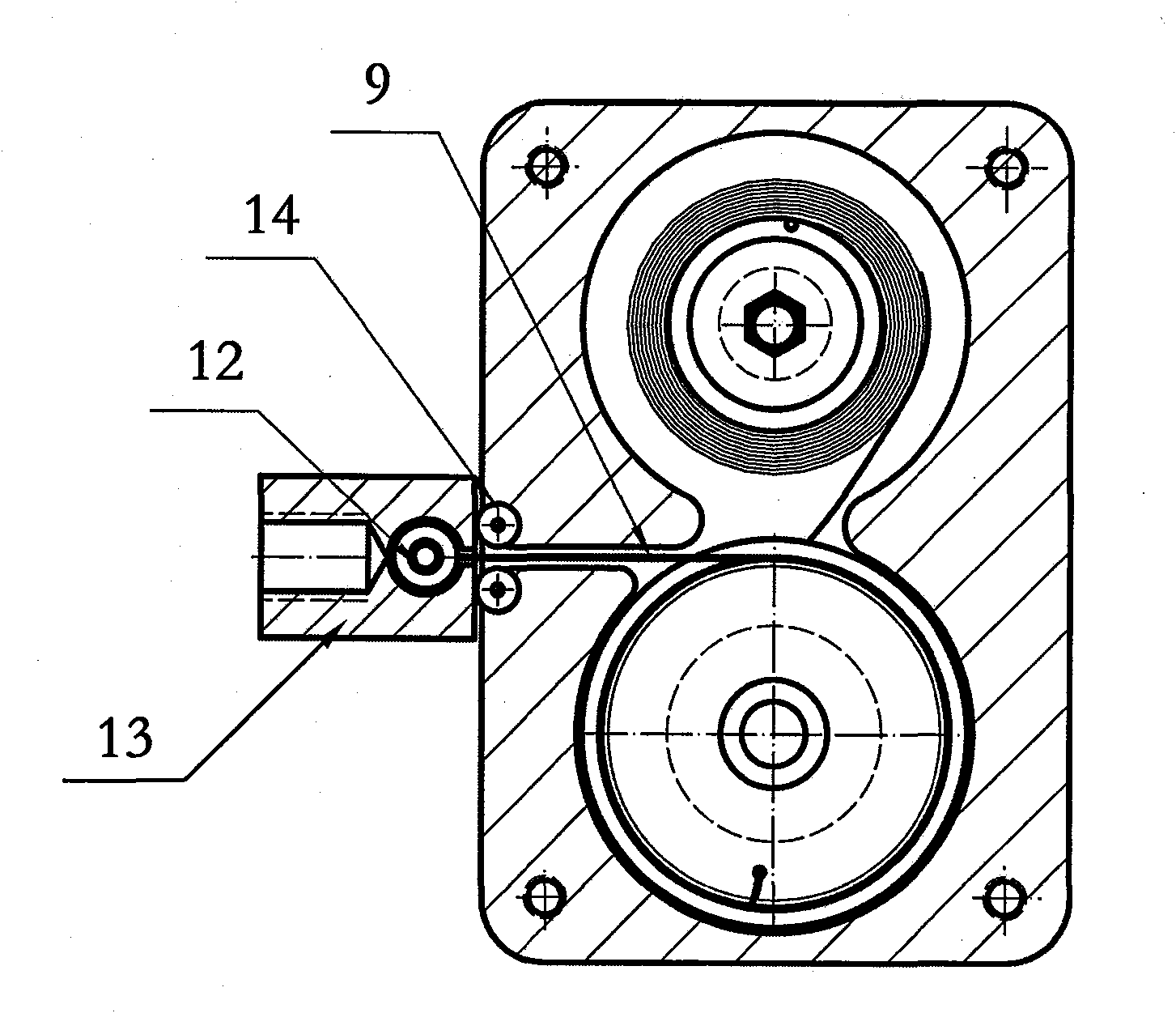

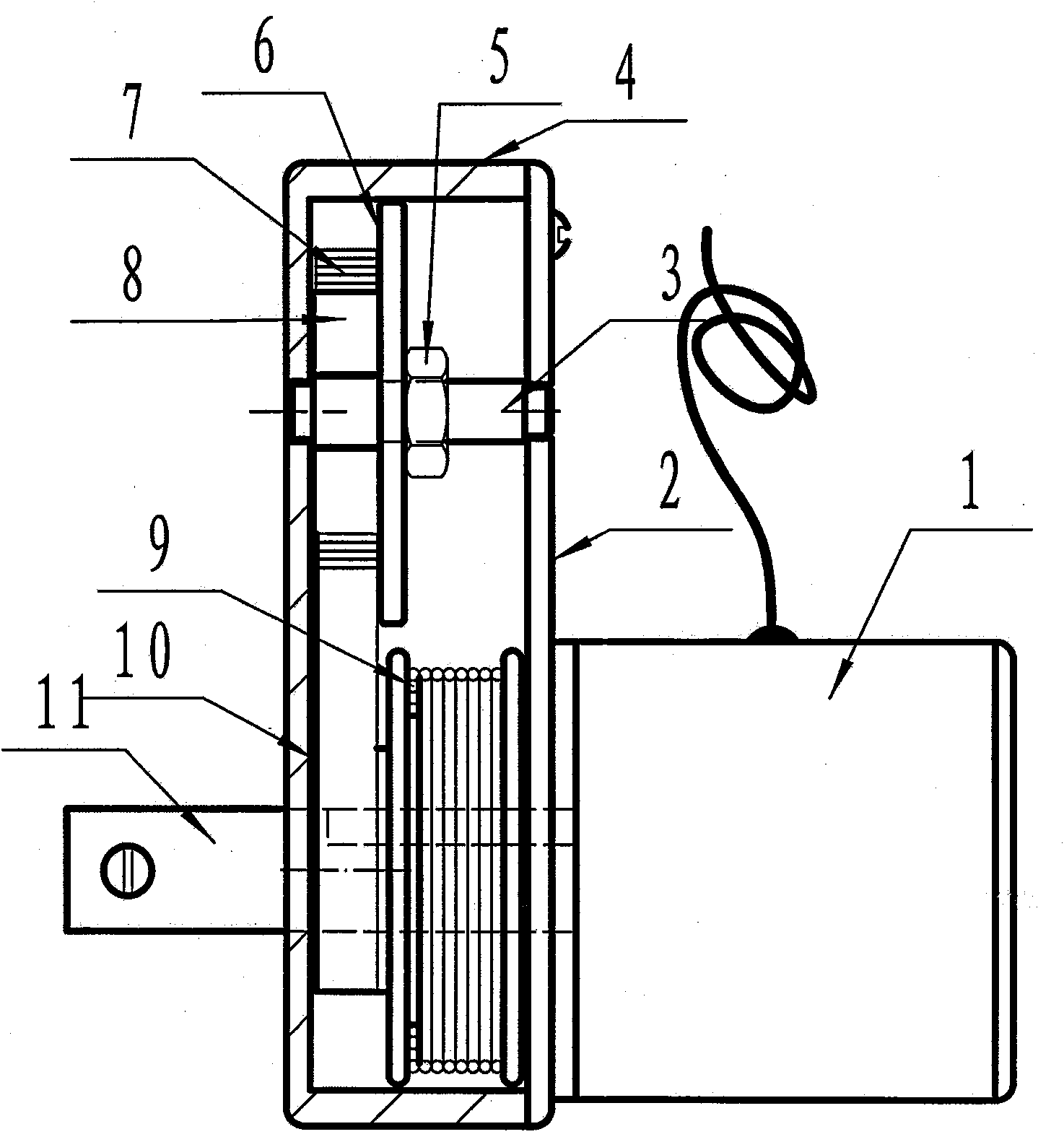

[0020] Such as figure 1 Shown is a schematic structural diagram of a specific embodiment of the sensor for high-voltage switch testing of the present invention, mainly consisting of a counter, a connector, and an energy storage mechanism. The energy storage mechanism includes a spring seat 8, a coil spring 7, a tape measure wheel 10, and a steel coil sheet 9 The coil spring 7 is installed on the spring seat 8, one end of the steel coil 9 is wound on the tape measure wheel 10, and the other end is wound on the coil spring 7, and the tape measure wheel 10 and the spring seat 8 are fixedly installed on the same plane;

[0021] The counter is composed of a grating, a light emitter, and a light receiver. The grating is in the shape of a disk, and the light emitter and the light receiver are located on both sides of the grating; in this embodiment, the finished encoder 1 is used for the counter. The encoder 1 is a rotary encoder, and the internal grating is disc-shaped, and there ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com