Semiconductor wafer transfer and process pretreatment equipment

A semiconductor and preprocessing technology, applied in semiconductor/solid-state device manufacturing, conveyor objects, electrical components, etc., can solve the problems of low wafer yield, low robot efficiency, structural design defects, etc., to reduce the movement distance, avoid Cross-contamination, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The semiconductor wafer transfer and pre-process pretreatment equipment proposed by the present invention are described as follows in conjunction with the accompanying drawings and embodiments.

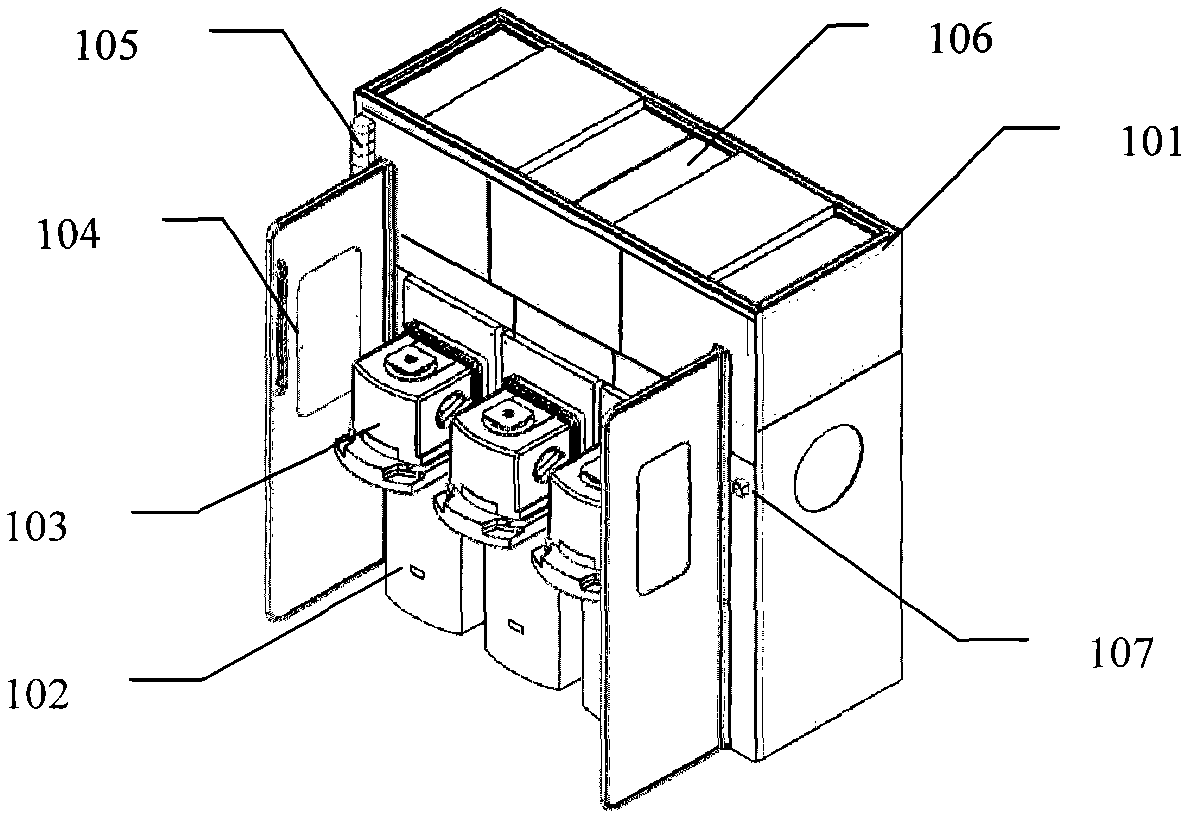

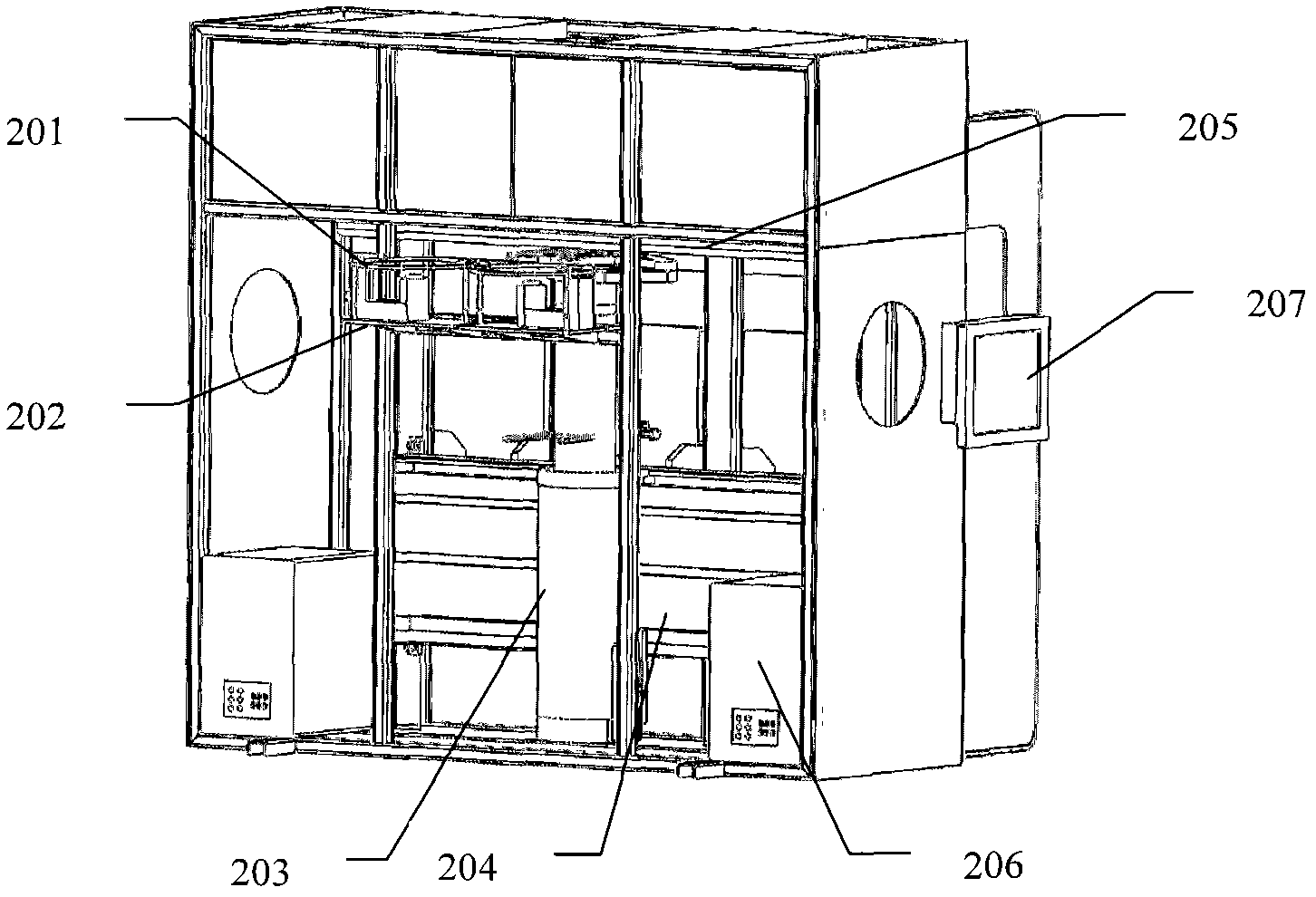

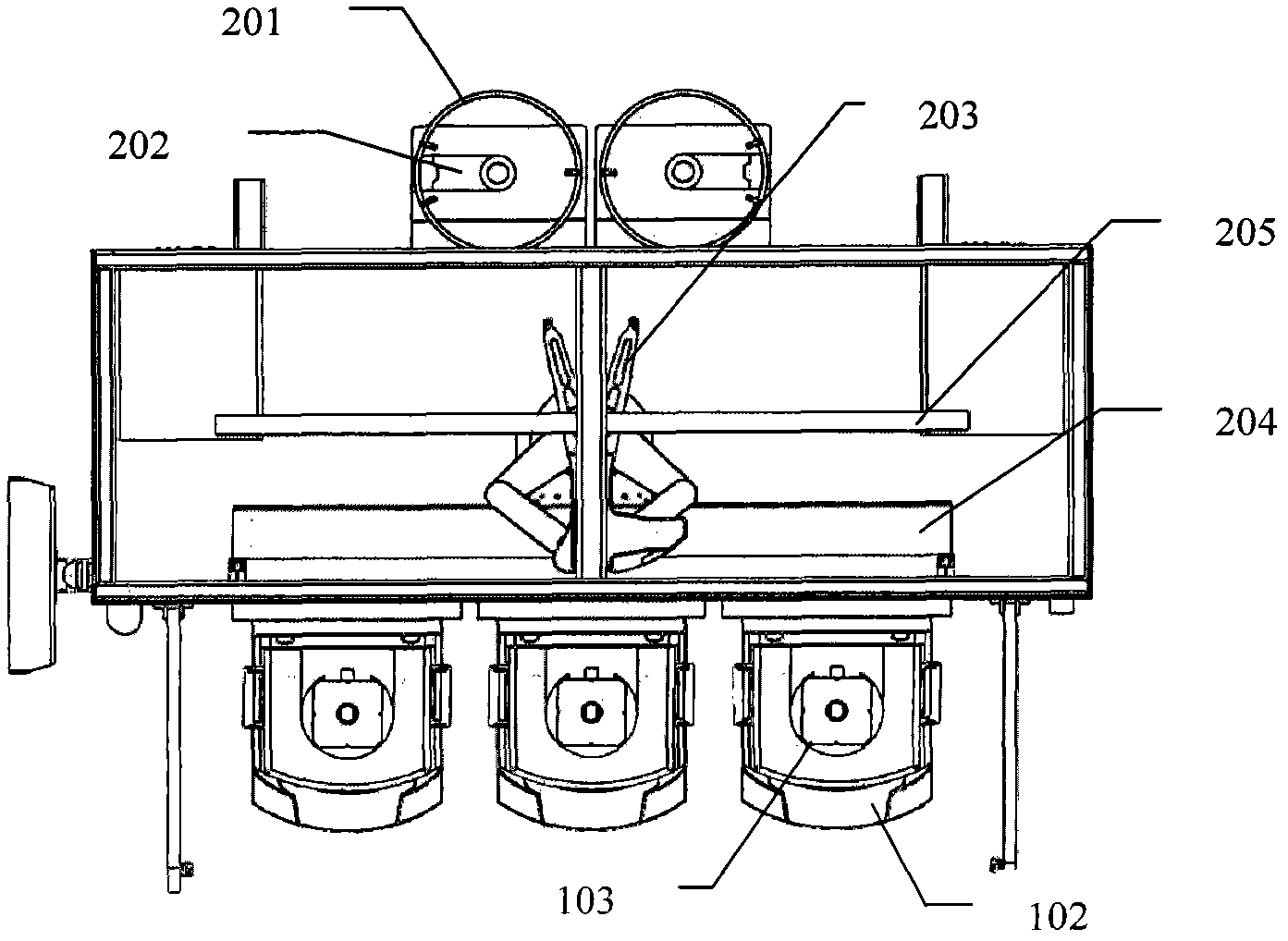

[0027] like Figure 1-3 As shown, the semiconductor wafer transfer and pre-process pretreatment equipment according to an embodiment of the present invention is supported by the equipment skeleton 101, which is in the shape of a rectangular parallelepiped cabinet, including:

[0028] Wafer storage box 103 is arranged on the front side of the equipment cabinet ( figure 1 The front shown) is used to carry semiconductor wafers; the wafer loading port 102 is arranged under the wafer storage box 103 and is used to carry the wafer storage box 103; the manipulator 203 is arranged inside the equipment for The input and output storage device 201 and the wafer correction device 202 on the back of the equipment grab the processed semiconductor wafers, place them on the wafer storage box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com