Method for preparing soybean milk

A production method and soybean milk technology, which is applied in the field of beverage processing, can solve the problems of affecting the taste, long pulping cycle, and insufficient crushing fineness of soybean milk, etc., and achieve the effects of improving the effect, overcoming easy deformation, and avoiding excessive washing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

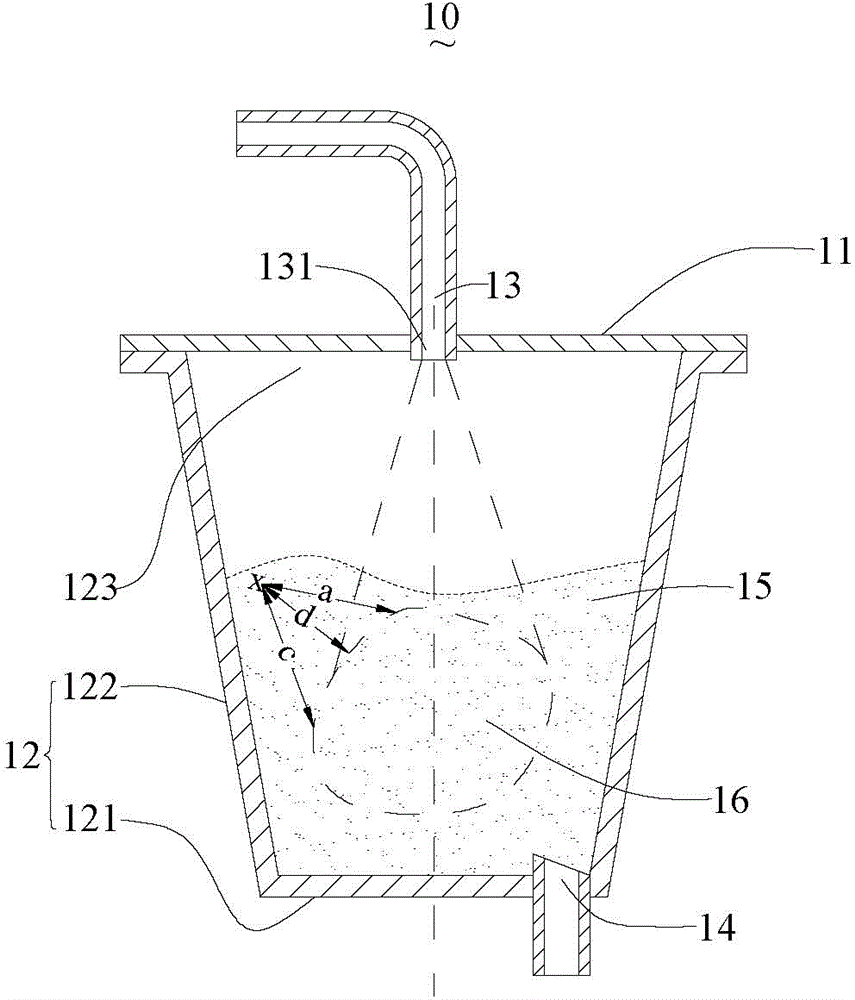

[0035] see figure 1 Shown is a schematic diagram of the first preferred embodiment of the soymilk production method of the present invention, the soymilk production method is to produce soymilk by introducing liquid into a material bag in the form of liquid flow, and the material bag 10 includes a cover 11 and a container 12, The container 12 includes a bottom wall 121 and a side wall 122 extending upward from the bottom wall 121 . The sidewall 122 surrounds the opening 123 . The cover 11 is disposed on the opening 123 . In order to ensure the flow effect of the liquid in the material bag, the inner surface of the side wall 122 of the material bag of the present invention is a smooth and streamlined design.

[0036] The material bag 10 is filled with bean powder 15, and the ratio of the volume of the bean powder 15 to the volume of the material bag 10 is less than 85%. When the volume ratio is greater than 85%, the remaining space in the material bag 10 is less, and the liq...

Embodiment approach 2

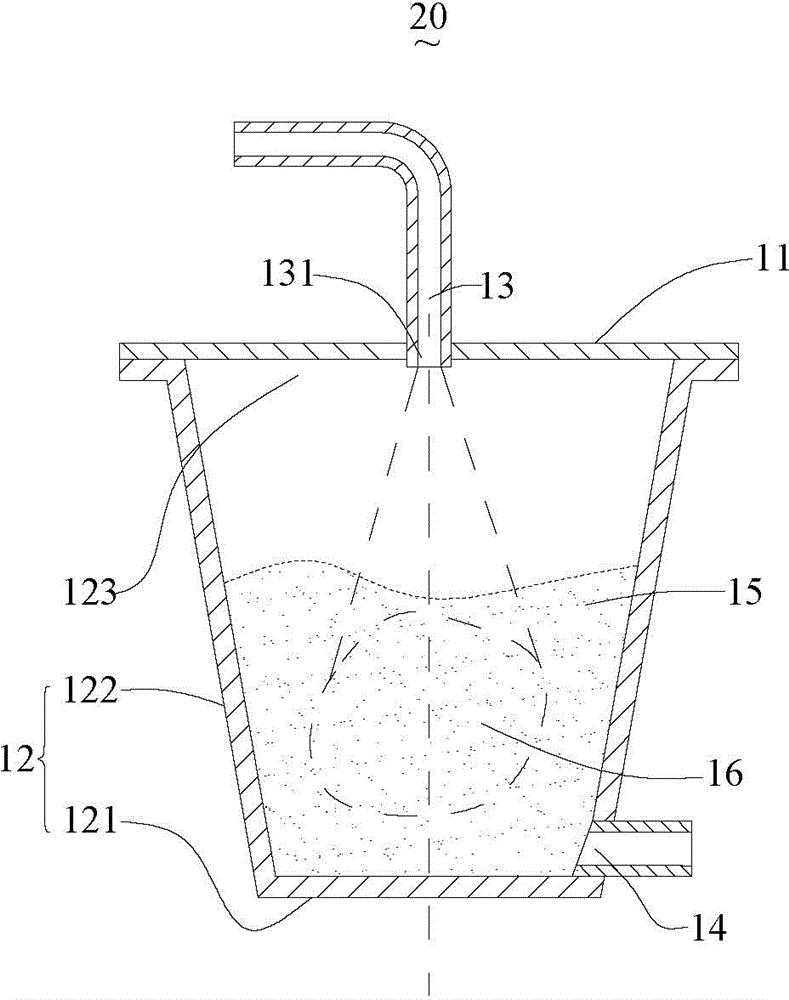

[0060] see figure 2 Compared with the first preferred embodiment, the second preferred embodiment of the soybean milk production method of the present invention differs in that: in step (2), the outlet hole 14 is provided on the side wall 122 of the bag 20 .

[0061] The ratio of the distance from the outlet hole 14 to the bottom wall 121 of the cartridge to the height of the side wall 122 is less than 1:4. That is, the outlet hole 14 is disposed on the side wall close to the bottom wall 121 . When the ratio is greater than 1:4, soy milk will remain in the space between the outlet hole 14 and the bottom wall 121 , resulting in waste. Therefore, in this embodiment, the distance ratio is set to 1:10.

[0062] The above conclusions will be verified through experiments below.

[0063] Table 4. Experimental report on the influence of the position of the extraction hole on brewing:

[0064]

[0065]

[0066] It can be seen from Table 4 that the smaller the ratio of the dis...

Embodiment approach 3

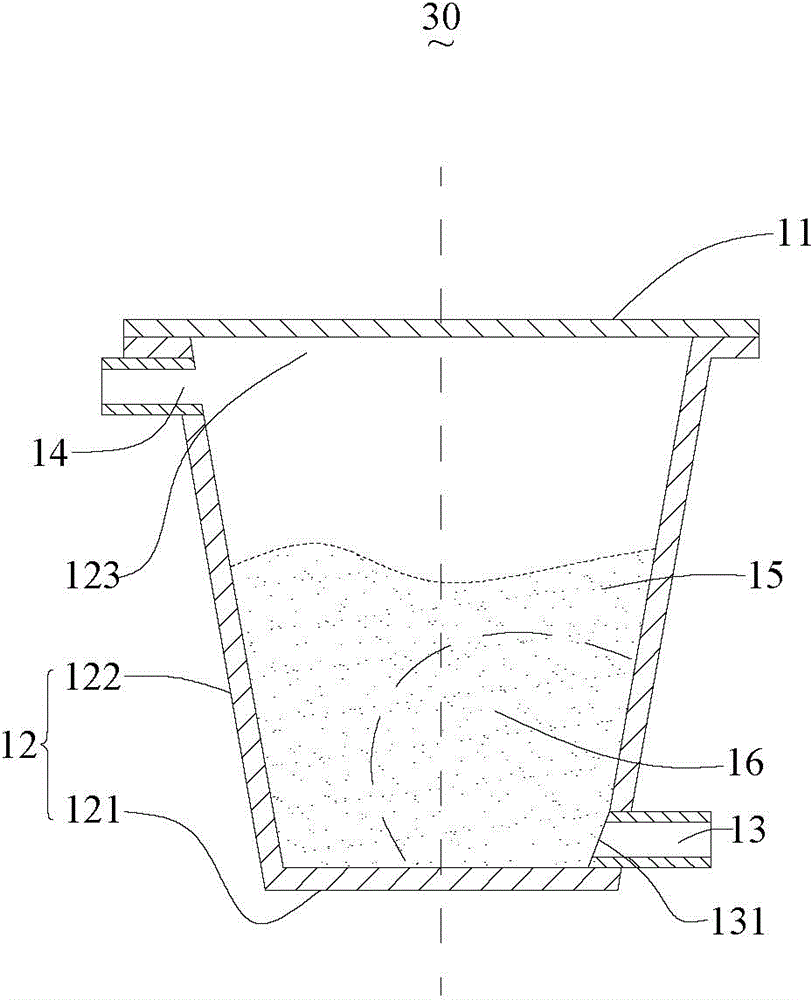

[0070] see image 3 The third preferred embodiment of the soymilk production method of the present invention shown is different from the second preferred embodiment in that: in step (1), the central axis of the injection point 131 and the central axis of the bag 30 vertical.

[0071] The outlet hole 14 is located on the side wall 122 , and the ratio of the distance between the injection point 131 and the outlet hole 14 on the central axis to the height of the bag side wall 122 is greater than 3:4. When the ratio is less than 3:4, that is, the distance between the injection point 131 and the outlet hole 14 is too close, and when the liquid flows, it is easy to form an optimal path between the two, resulting in that the liquid cannot be well mixed with the soybean powder. Therefore, this embodiment sets the ratio to 9:10.

[0072] The above conclusions will be verified through experiments below.

[0073] Table 5. Experimental report on the influence of the relative position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com