Lower anterior tooth resin filler

A filler and resin technology, which is applied to the field of lower anterior tooth resin filler, can solve the problems of affecting the modification effect, prolong the operation time, etc., and achieve the effects of simple structure, broad market prospect and novel design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

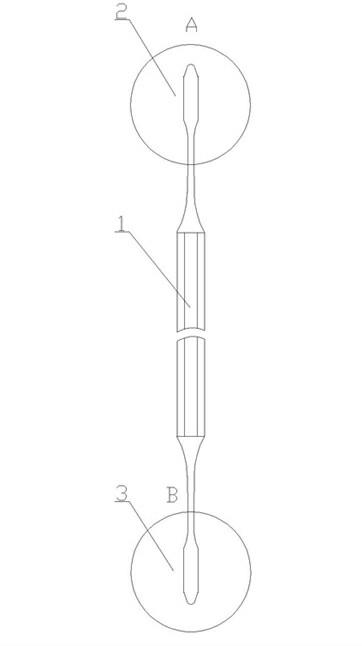

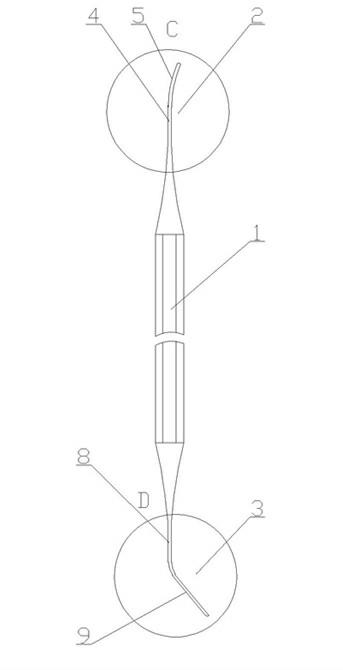

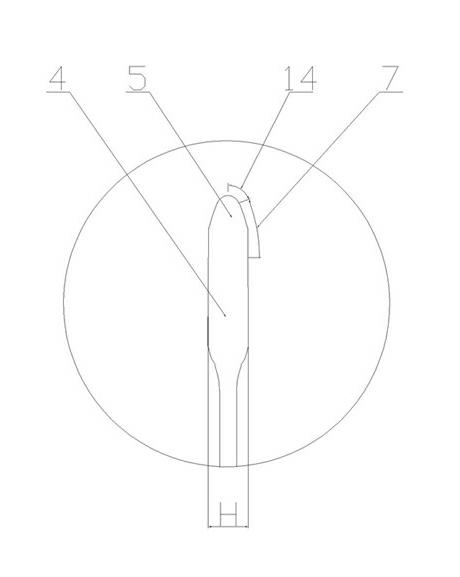

[0013] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 6 Shown: a resin filler for lower anterior teeth, including a shaft 1, an upper filling head 2 and a lower filling head 3 are respectively arranged at both ends of the shaft 1, the upper filling head 2 includes an upper straight part 4, the upper The range of the width H of the straight part 4 is 2.5-3 millimeters, the best is 2.7 millimeters, the range of the thickness D is 0.3-0.5 millimeters, the best is 0.4 millimeters; The upper curved part 5 with the curved side of the plane, the upper straight part 4 and the upper curved part 5 are different planes, and there is a smooth transition between the two; there is a centerline in the axial section of the upper curved part 5, and this centerline is the first Curve 6, the range of curvature radius R1 of the first curve 6 is 6-10 mm, preferably 8 mm, and the range of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com