Manipulator positioning mechanism for rotary filling machine

A positioning mechanism and manipulator technology, applied in the direction of manipulators, program control manipulators, manufacturing tools, etc., can solve the problems of high cost, complex structure, difficult installation and debugging, etc., and achieve the effect of low cost, simple and compact structure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

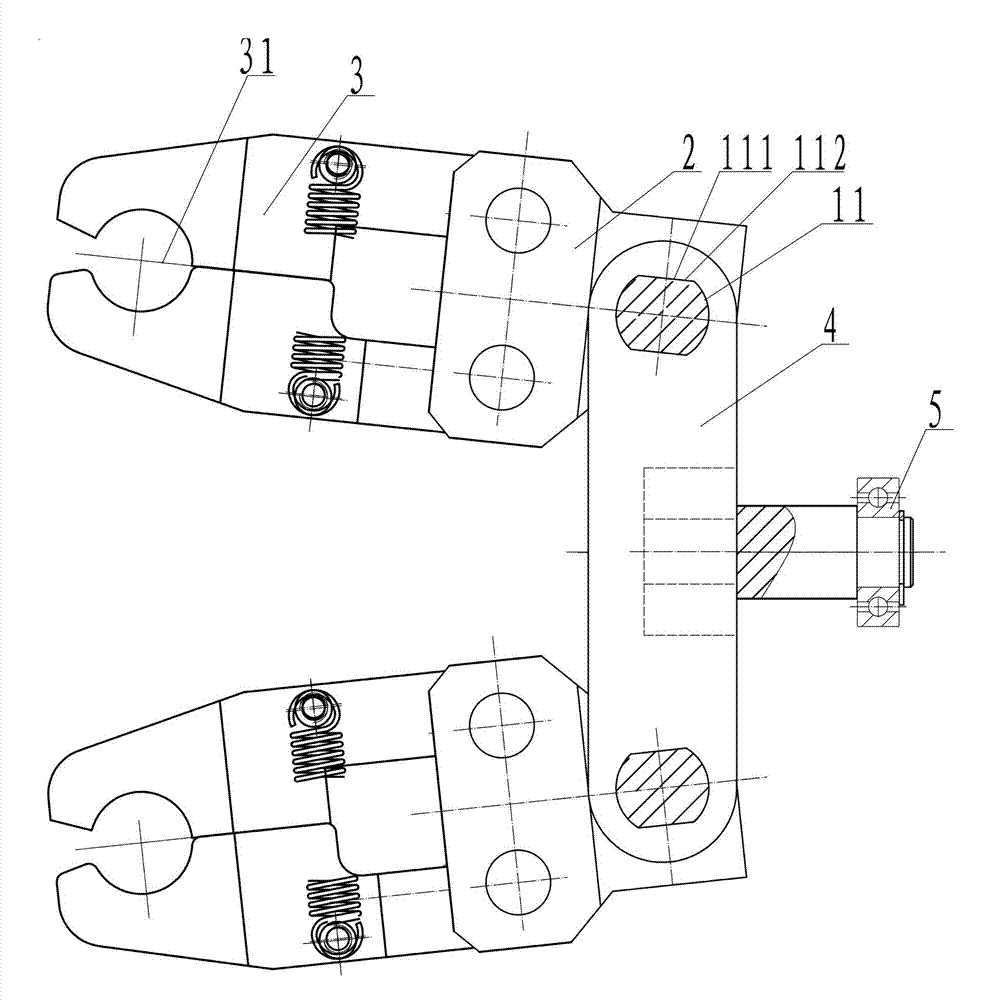

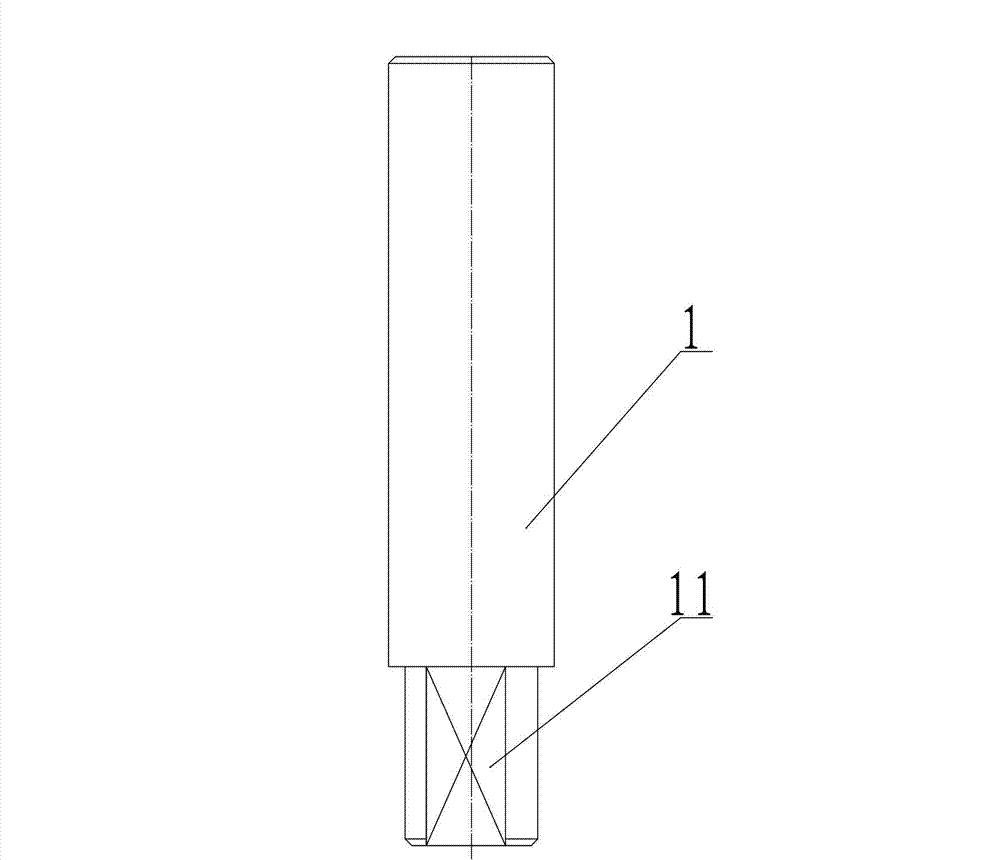

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the manipulator positioning mechanism used in the rotary filling machine of the present invention includes a guide part 11 formed on the manipulator lifting shaft 1 and a positioning hole 21 opened on the manipulator chuck seat 2 and cooperating with the guide part 11. The projection line 112 of at least one guide surface 111 on the part 11 in the horizontal direction is parallel to the clamping centerline 31 of the manipulator 3 . Through the above structure, the manipulator 3 can be positioned at any desired position in the circumferential direction, and the structure is simple and compact, and the cost is low; moreover, since the guide bearing 6 and the guide sleeve 7 do not need to be introduced, the installation and debugging are also convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com