Method for manufacturing automatic blackboard eraser

An automatic blackboard eraser and its production method technology, which is applied in the field of teaching aids, can solve the problems of chalk dust sucking into the air duct, time-consuming and labor-intensive, and not being able to erase the blackboard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

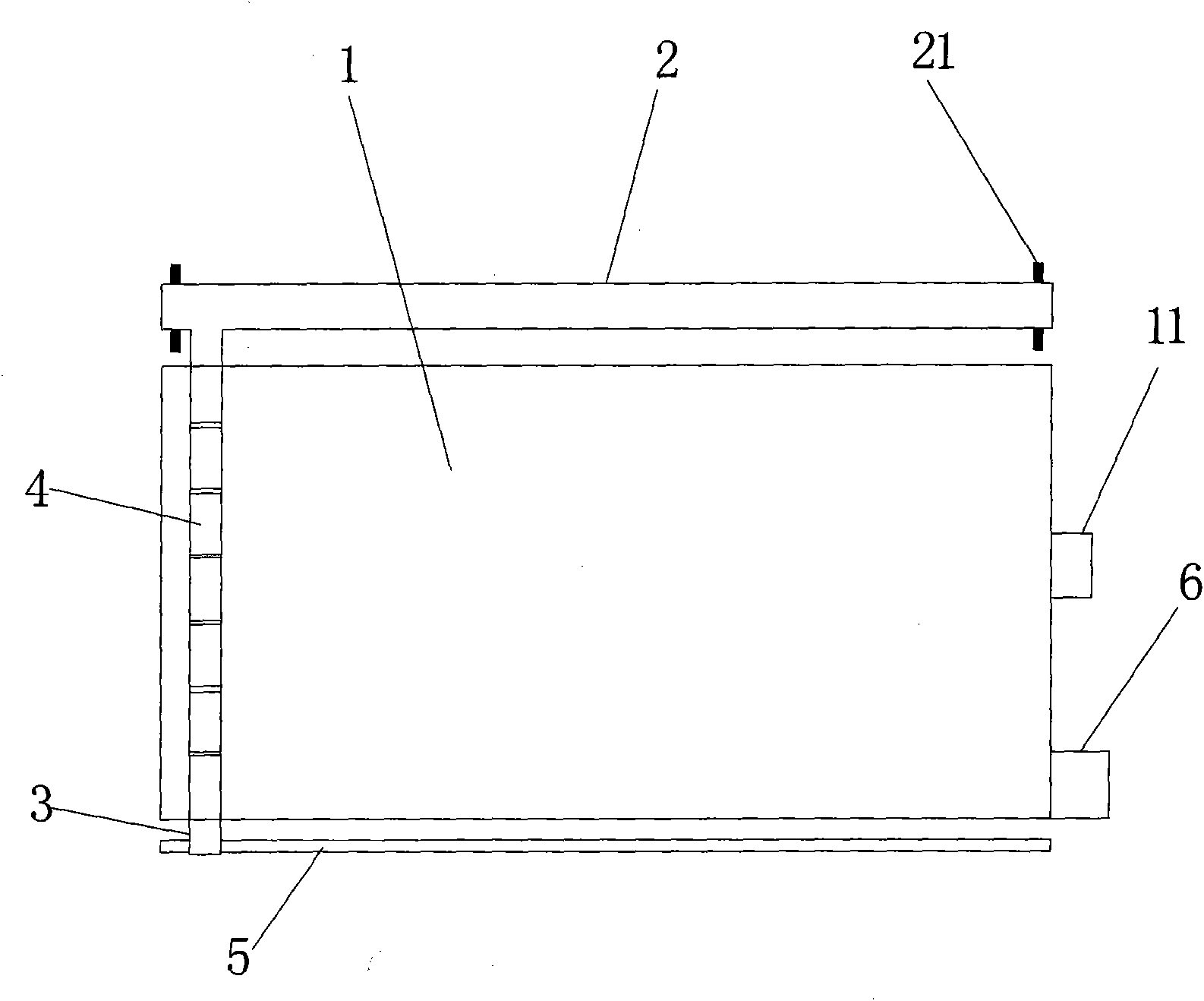

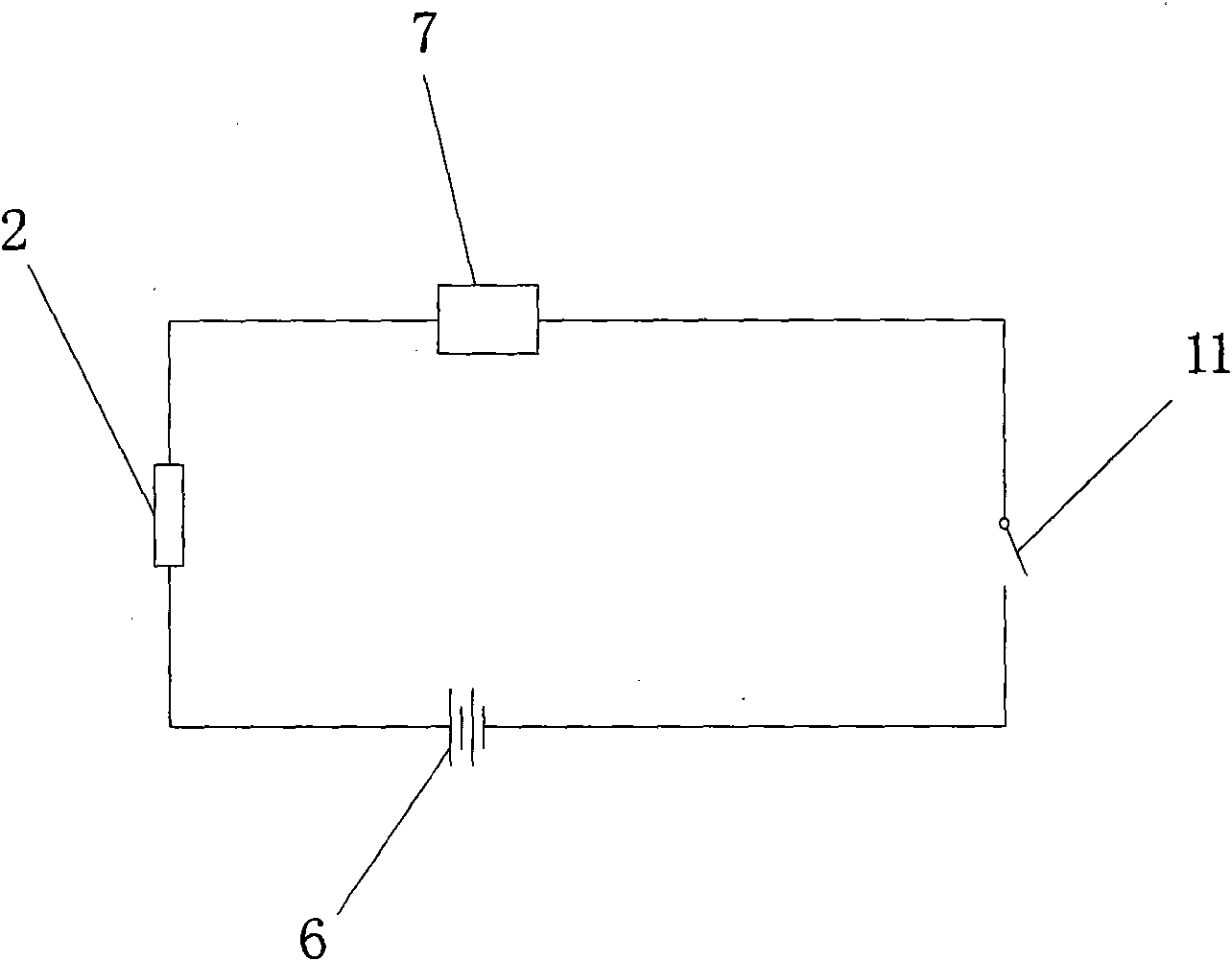

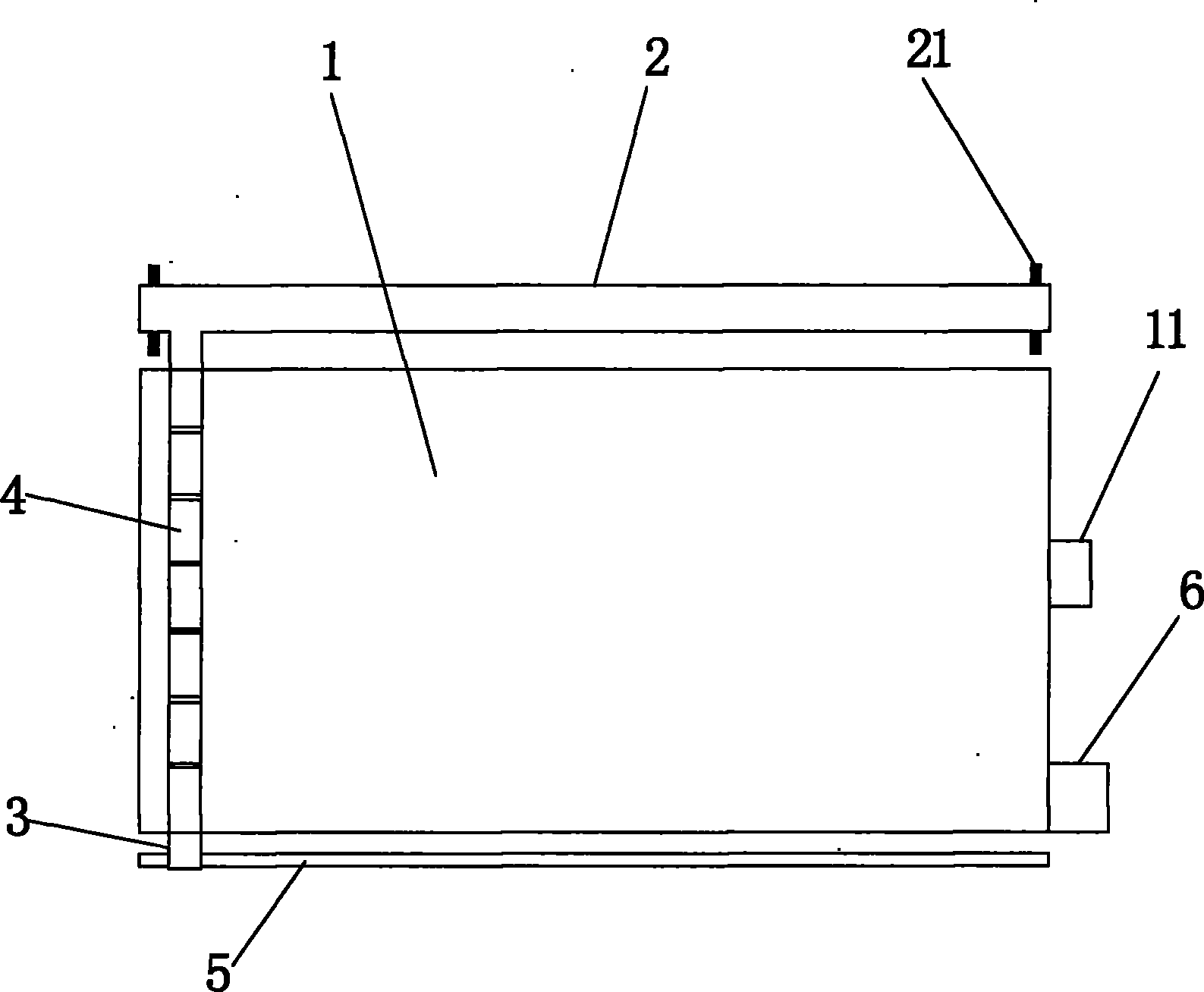

[0023] Such as figure 1 and figure 2 Shown, a kind of manufacture method of automatic blackboard eraser comprises blackboard 1, traction device 2, blackboard eraser groove 3, blackboard eraser 4, slide bar 5, wherein, described blackboard 1 top has a traction device 2, and below has a slide bar 5 , blackboard eraser groove 3 two ends link to each other with traction device 2 and slide bar 5 respectively, blackboard eraser 4 is arranged in blackboard eraser groove 3. The traction device 2 includes two pulleys 21 and a belt.

[0024] A kind of manufacture method of automatic blackboard eraser, wherein, comprises the following steps:

[0025] Step 1, fix the traction device 2 above the blackboard 1, and fix the slide bar 5 below the blackboard 1;

[0026] Step 2, fix one end of the blackboard eraser groove 3 on the belt of the traction device 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com