Treatment device for fume generated in conversion process of vanadium pentoxide by ammonium metavanadate

A technology of vanadium pentoxide and ammonium metavanadate is applied in gas treatment, ammonium sulfate, alkali metal chloride and other directions to achieve the effects of reducing air pollution, avoiding impacts and creating economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

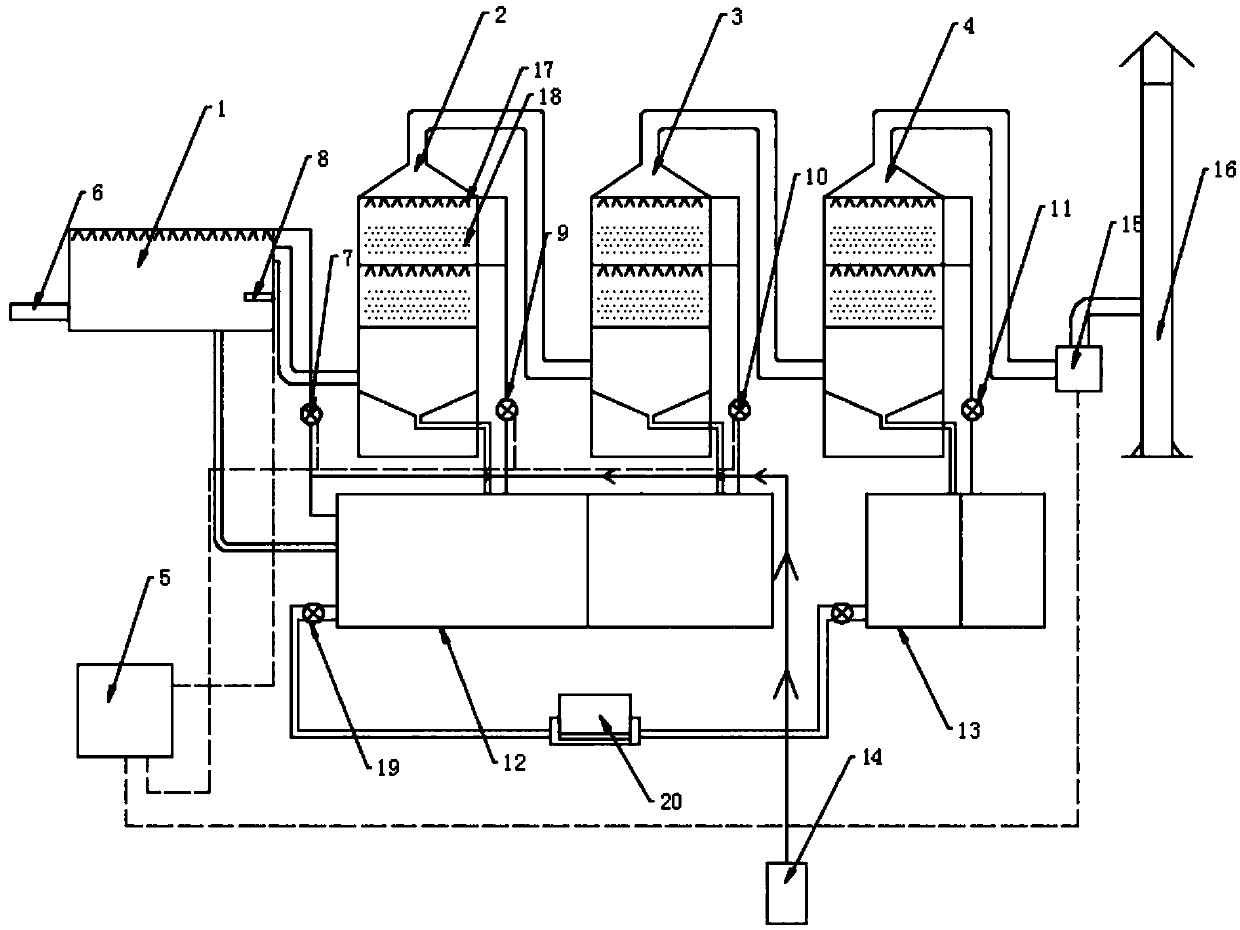

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] In conjunction with the accompanying drawings, a flue gas treatment device for converting ammonium metavanadate into vanadium pentoxide is characterized in that it includes a primary spray cooling device 1, a secondary sulfuric acid spray device 2, a tertiary sulfuric acid spray device 3, Four-stage lye spraying device 4, power control box 5, dilute sulfuric acid pool 12, lye pool 13 and tap water inlet pipe 14, said primary spray cooling device 1, secondary sulfuric acid spraying device 2, and tertiary sulfuric acid The spraying device 3 and the four-stage lye spraying device 4 are connected successively. One side of the first-stage spray cooling device 1 is provided with an air inlet 6, and the other side is provided with a first-stage anti-corrosion plastic self-priming pump 7. The first-stage spray cooling device 1 is internally provided with a the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com