Novel sludge thickening and dewatering integral machine with deviation-correcting device

A technology of deviation correcting device and deviation correcting cylinder, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve problems such as unstable operation, low efficiency, and affecting operating efficiency, and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] specific implementation plan

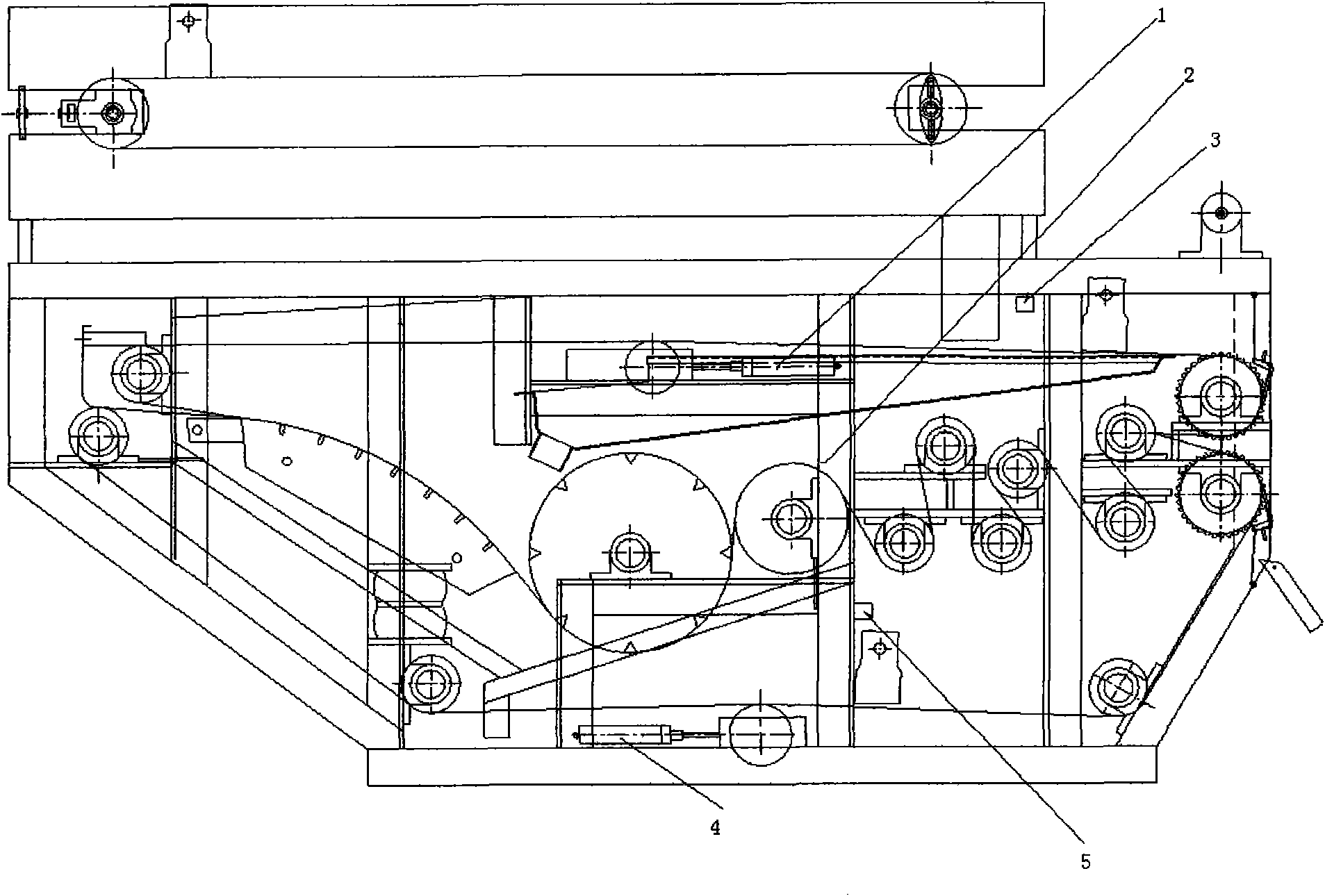

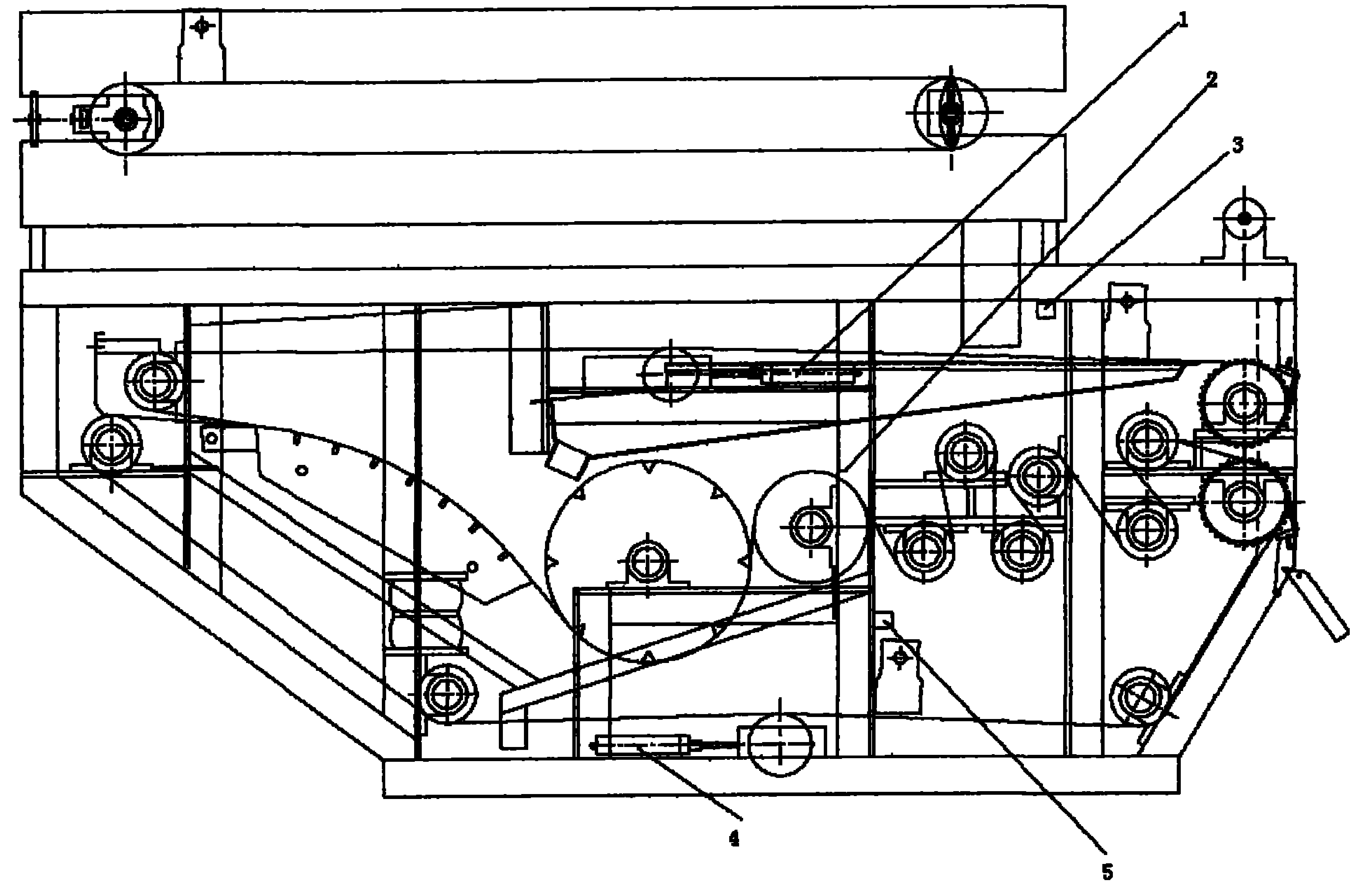

[0007] The present invention is characterized by comprising: an upper filter belt deviation correction cylinder 1, a filter belt limit limit switch 2, an upper filter belt induction switch 3, a lower filter belt deviation correction cylinder 4, and a lower filter belt induction switch 5. The whole deviation correction device is divided into an upper deviation correction device and a lower deviation correction device. The upper deviation correction device is composed of an upper filter belt sensor switch 3 and an upper filter belt deviation correction cylinder 1, which are installed symmetrically on the left and right sides of the filter belt (see Figure 1 for the position). Install symmetrically on the left and right sides of the filter belt respectively (see Figure 3 for the position). The lower deviation correcting device is composed of the lower filter belt deviation correcting cylinder 4 and the lower filter belt induction switch 5; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com