Method using vanes to discharge flue gas and flue gas drain valve

A smoke emission and vane technology, which is applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems that the smoke exhaust area affects the smoke exhaust effect, poor sealing, and has not been resolved, so as to achieve the effect of eliminating smoke leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

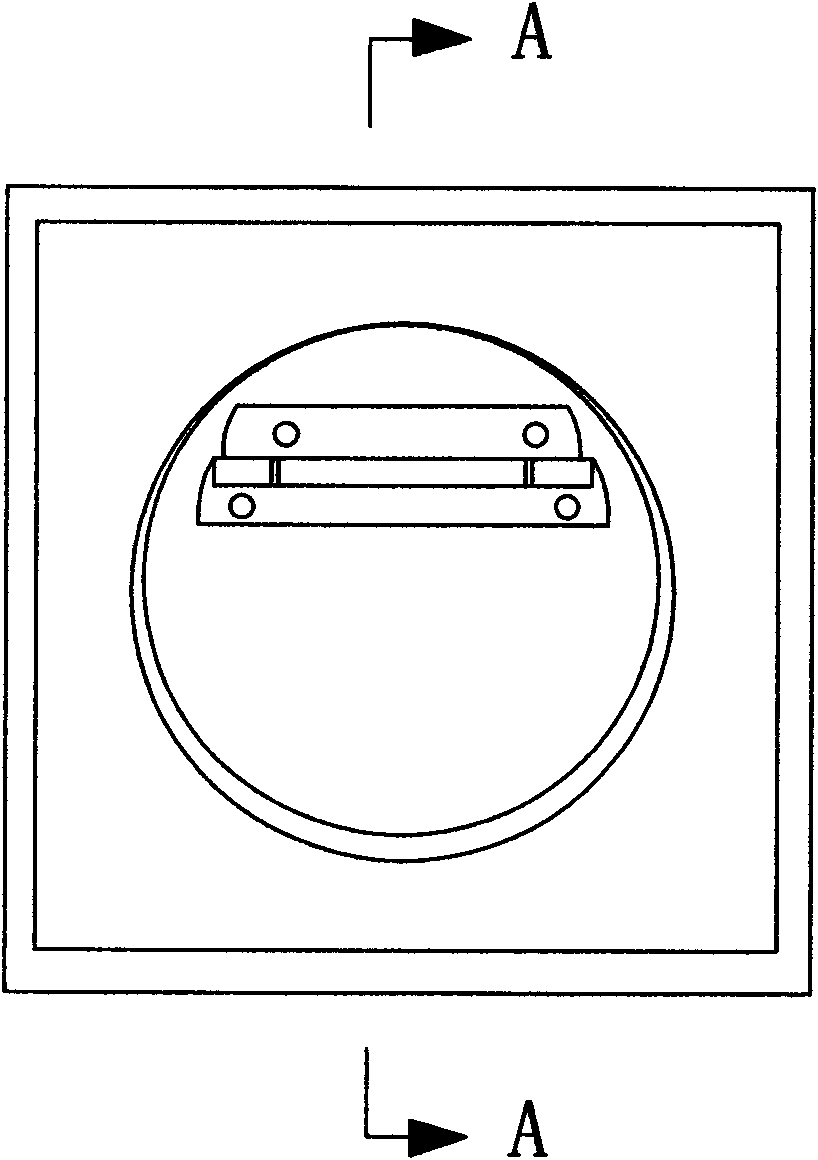

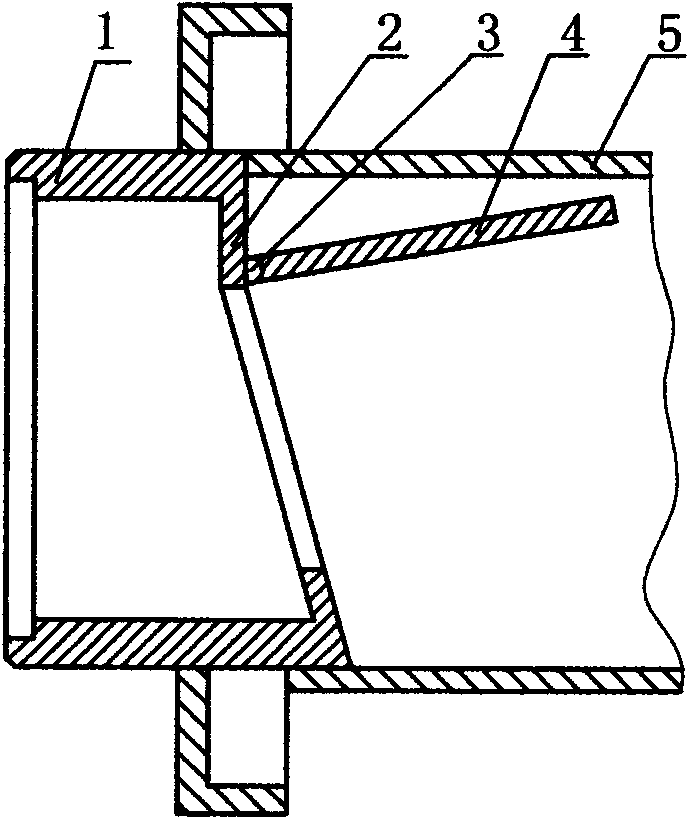

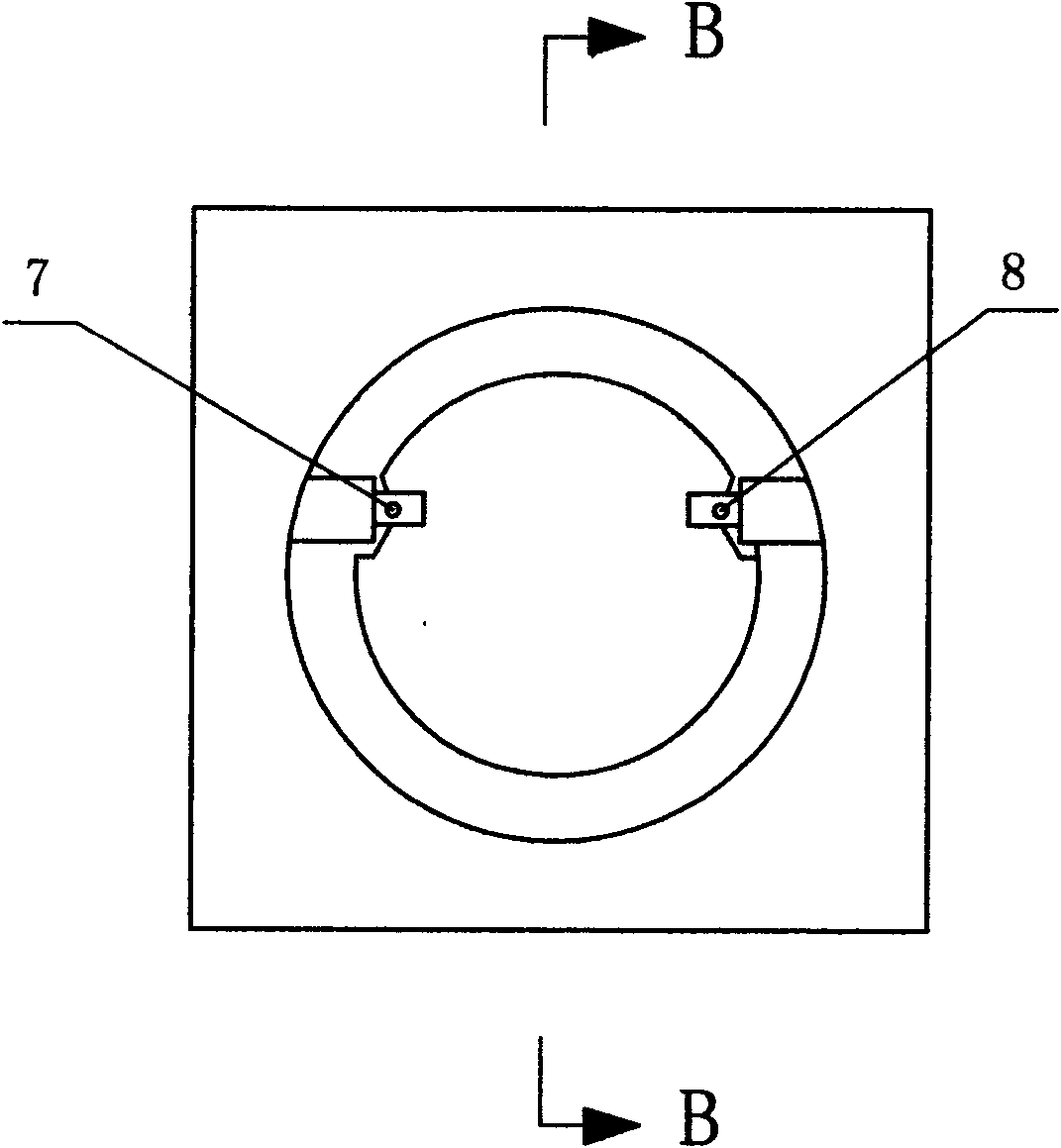

[0031] A method of using blades to discharge smoke according to the present invention includes a valve body and blades, and a smoke exhaust port is set in the valve body, the blades are located in the smoke exhaust port, and the blades can rotate around their rotating shafts. It is characterized in that: two blades are used , the opening and closing of each blade is left and right. After the smoke exhaust starts, the two blades open around their rotating shafts, and the smoke exhaust port is unblocked; A top-to-bottom sloping block is arranged in the valve body, and the inside of the block is a smoke exhaust port. After each blade is closed, it is attached to the rear surface of the blade block.

[0032] The specific structural examples of the smoke exhaust method of the present invention are set forth below.

[0033] Such as Figure 5 , 6 , 7, and 8, the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com