Waste gas desulfurization and inert gas supply integrated device

A technology for desulfurization of waste gas and inert gas, applied in gas treatment, use of liquid separation agents, chemical instruments and methods, etc., can solve problems such as system complexity, and achieve the effects of optimizing system configuration, reducing floor space, and reducing system costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

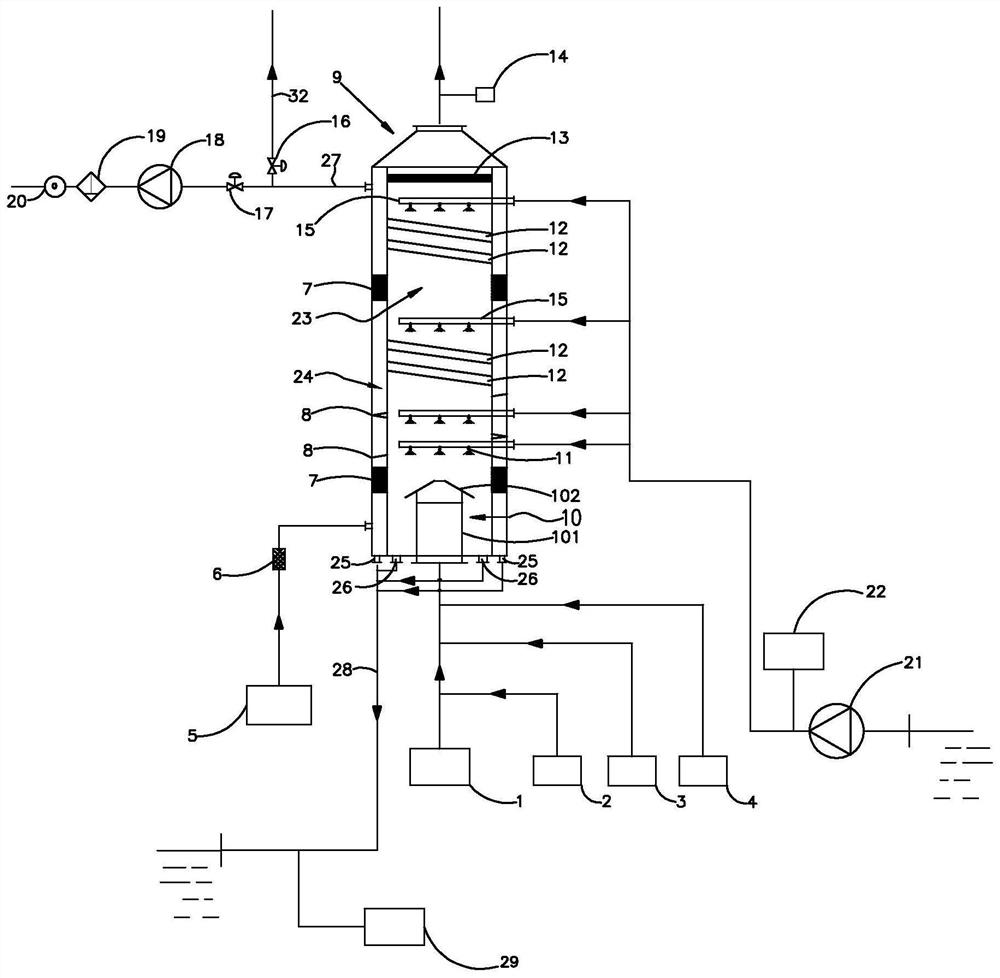

[0054] A 300,000-ton oil tanker is equipped with 1 main engine, 3 auxiliary engines, and 1 oil-fired boiler, with a total power of about 30MW. The ratio of sulfur to carbon is less than 4.3 required by IMO, and the amount of inert gas supply can meet various working conditions such as loading and unloading of the ship, and the application effect is very good.

[0055] The embodiment of the present invention also provides an oil tanker equipped with the above-mentioned integrated device for exhaust gas desulfurization and inert gas supply, the engine exhaust gas inlet at the bottom of the inner tower is connected to the ship engine, and the boiler exhaust gas inlet at the bottom of the outer tower It is connected to the oil-fired boiler, and the boiler exhaust gas discharge pipeline is connected to the oil tank of the oil tanker.

[0056] Oil tankers are currently a mainstream ship type in the shipping market, and the inert gas system is an essential system for oil tankers, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com