Dual power supply system

A dual power supply and power supply technology, applied in the field of electronics, can solve the problems of waste of power consumption, increase of overhead, waste of chip area, etc., to reduce the design cost, reduce the area, and solve the effect of current backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

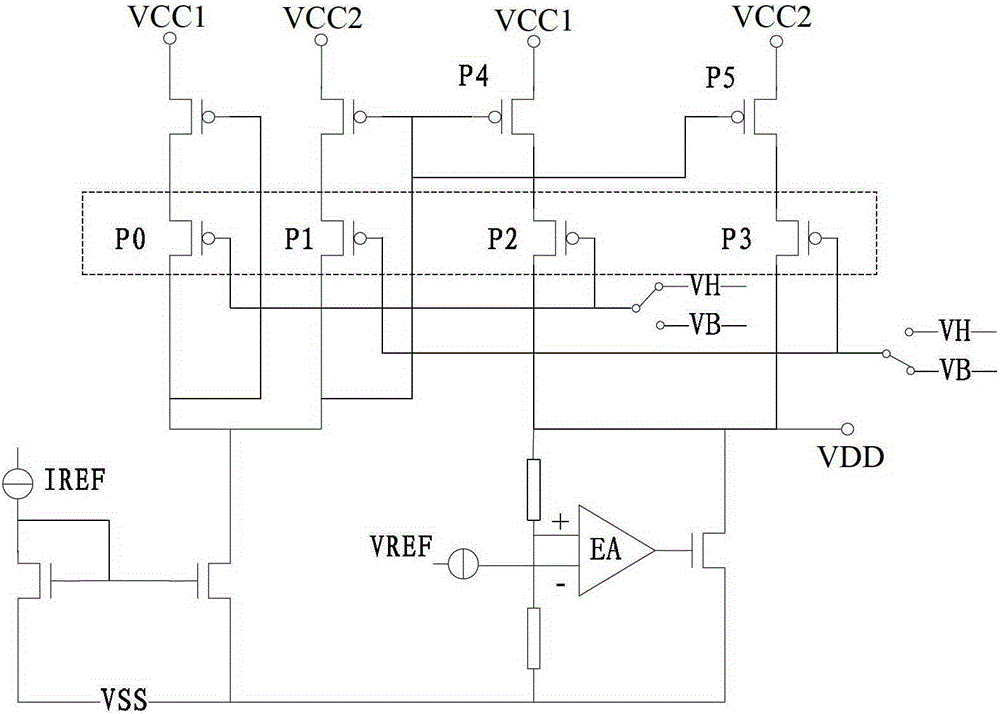

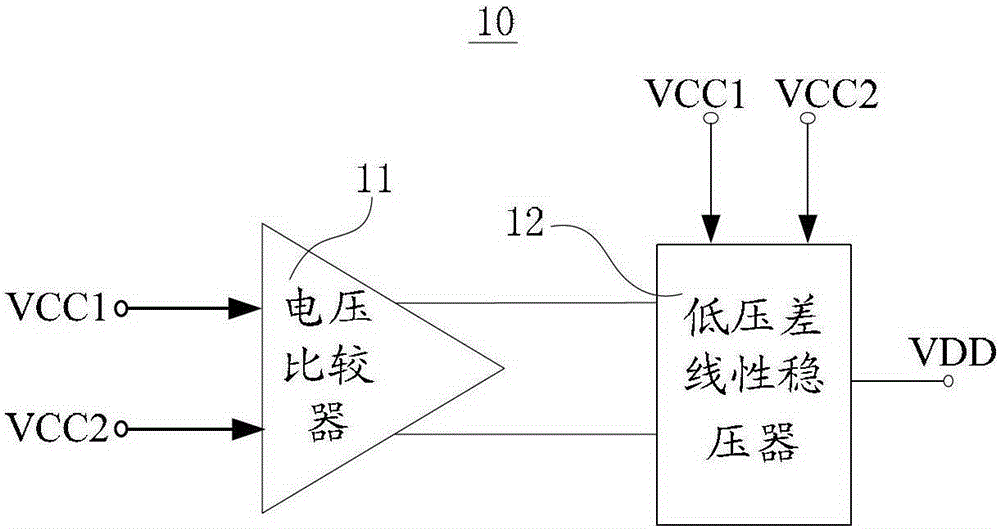

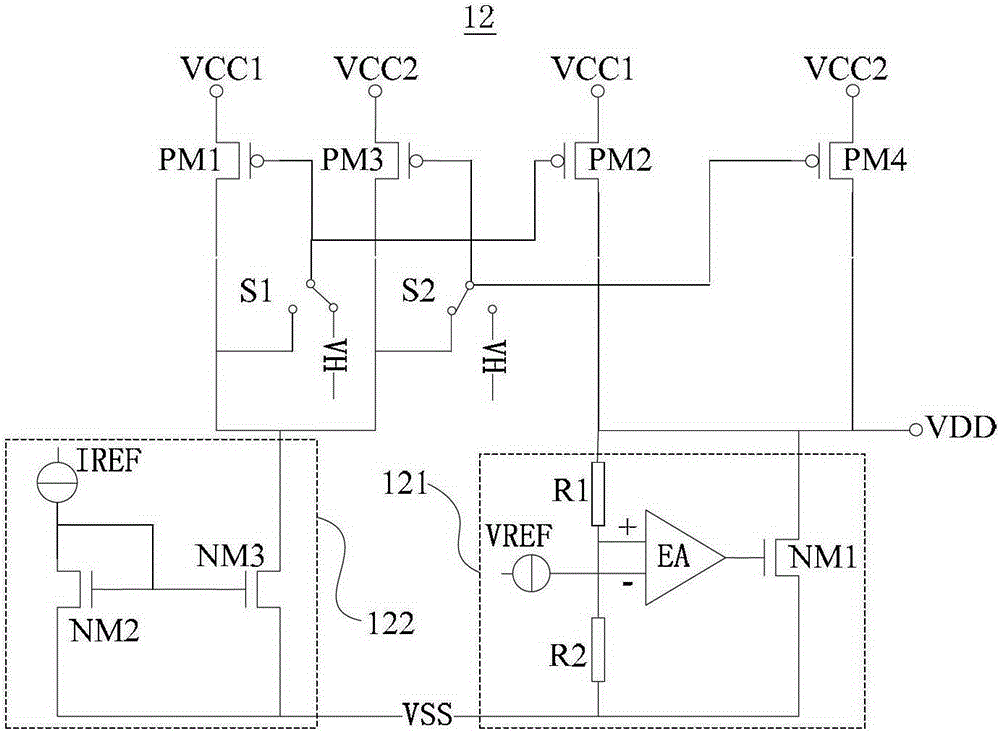

[0019] Such as figure 2 as shown, figure 2 It is a structural schematic diagram of the dual power supply system of the present invention. The dual power supply system 10 includes a voltage comparator 11 and a low dropout linear regulator 12 . The voltage comparator 11 is connected with the low dropout linear regulator 12, wherein the voltage comparator 11 compares the first power supply VCC1 and the second power supply VCC2, judges which power supply is higher or lower, and then generates a control signal according to the comparison result to control the needs which power supply. The low-dropout linear voltage regulator 12 performs low-dropout linear voltage regulation on the first power supply VCC1 and / or the second power supply VCC2 according to the control signal. The differential linear voltage regulator 12 simultaneously performs low-dropou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com