Cooling box for tunnel sterilizing dryer and dryer of cooling box

A dryer and tunnel technology, applied in dryers, packaging sterilization, drying of solid materials, etc., can solve the problems of reducing the sterilization and drying effect of the bottle body, reducing the cooling effect of the bottle body, and turbulent flow in the cooling section. , to achieve the effect of enhancing sterilization and drying effect, ensuring cooling effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

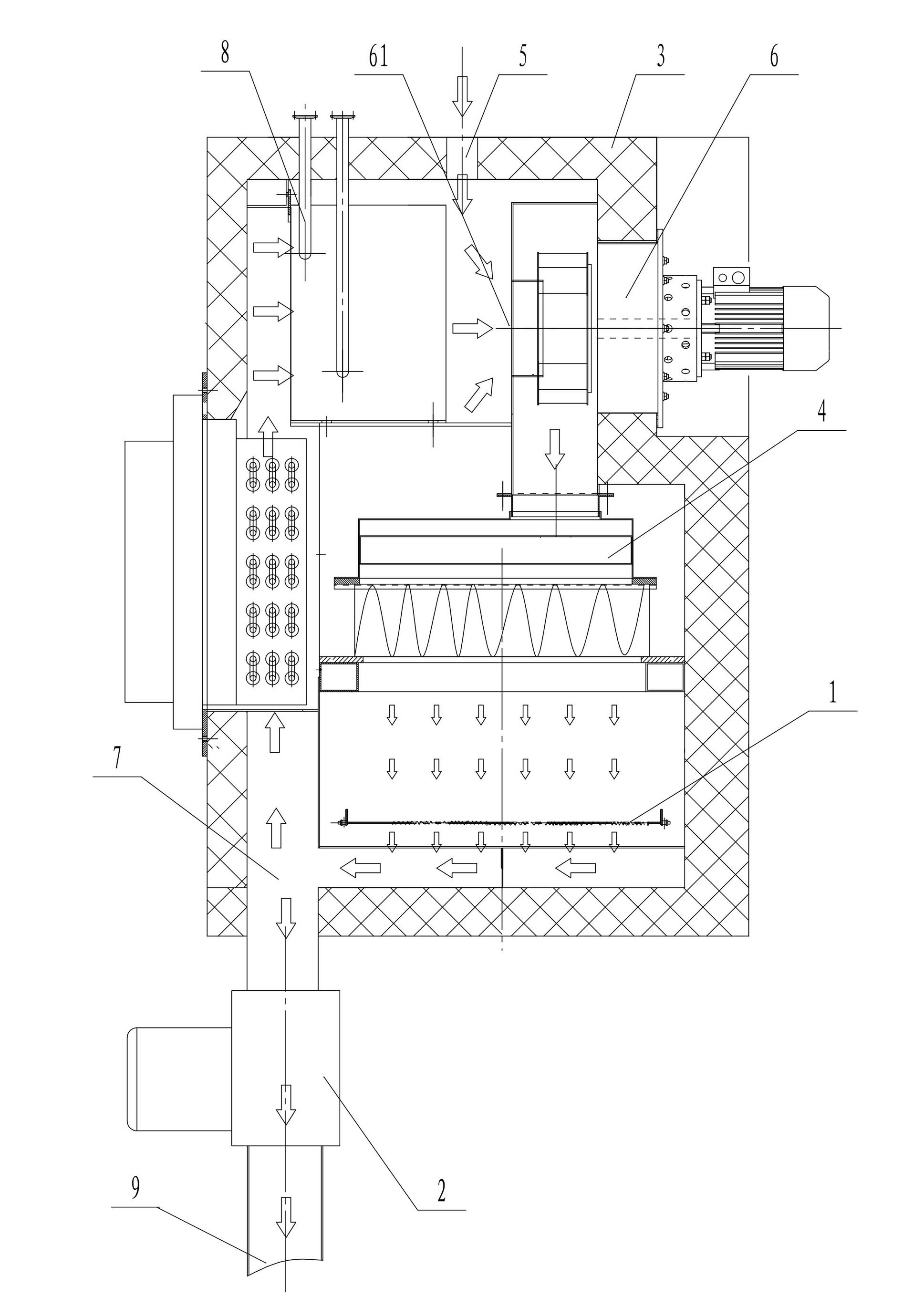

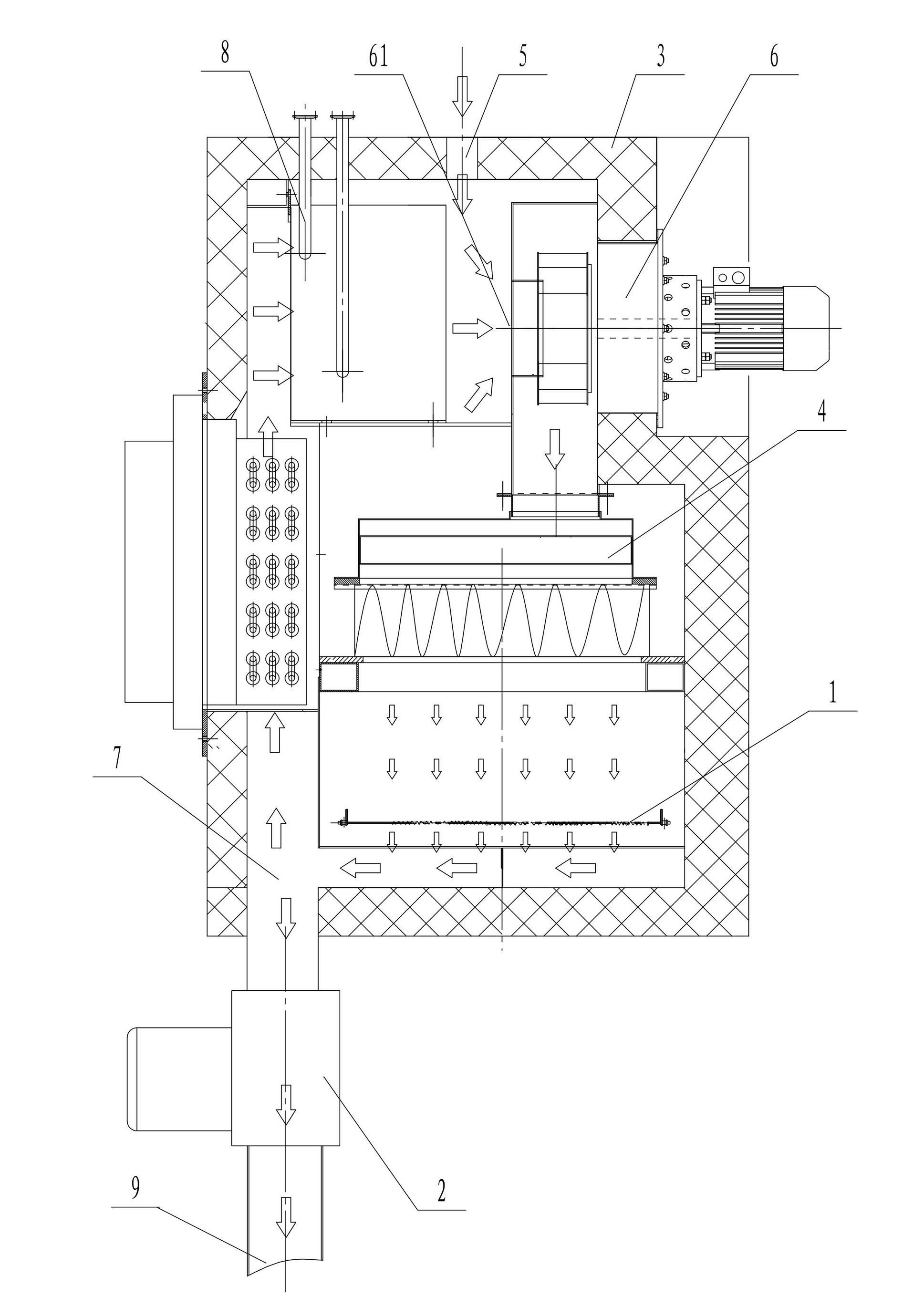

[0020] Such as figure 1 As shown, the cooling box for the tunnel sterilization dryer of the present invention includes a cooling box 3, a return air passage 7 arranged in the cooling box 3, and a cooling box arranged in sequence from top to bottom in the cooling box 3. Cooling fan 6, cooling laminar flow cover 4 and bottle conveying mechanism 1, the outer bottom of the cooling box 3 is provided with an exhaust assembly connected with the return air passage 7, and the outlet end of the return air passage 7 is located at the air inlet of the cooling fan 6 On one side, a cooling assembly 8 is installed in the return air passage 7, and the cooling box 3 is provided with a supplementary air inlet 5 that communicates the air inlet 61 of the cooling fan 6 with the outside world. By offering the supplementary air port that makes the air inle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap