Ultrasonic wave measuring method for liquid flowing speed and flow of pressure pipeline

A liquid flow and measurement method technology, applied in the field of measurement, can solve problems such as poor accuracy, achieve the effect of improving flow measurement accuracy and eliminating influence errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

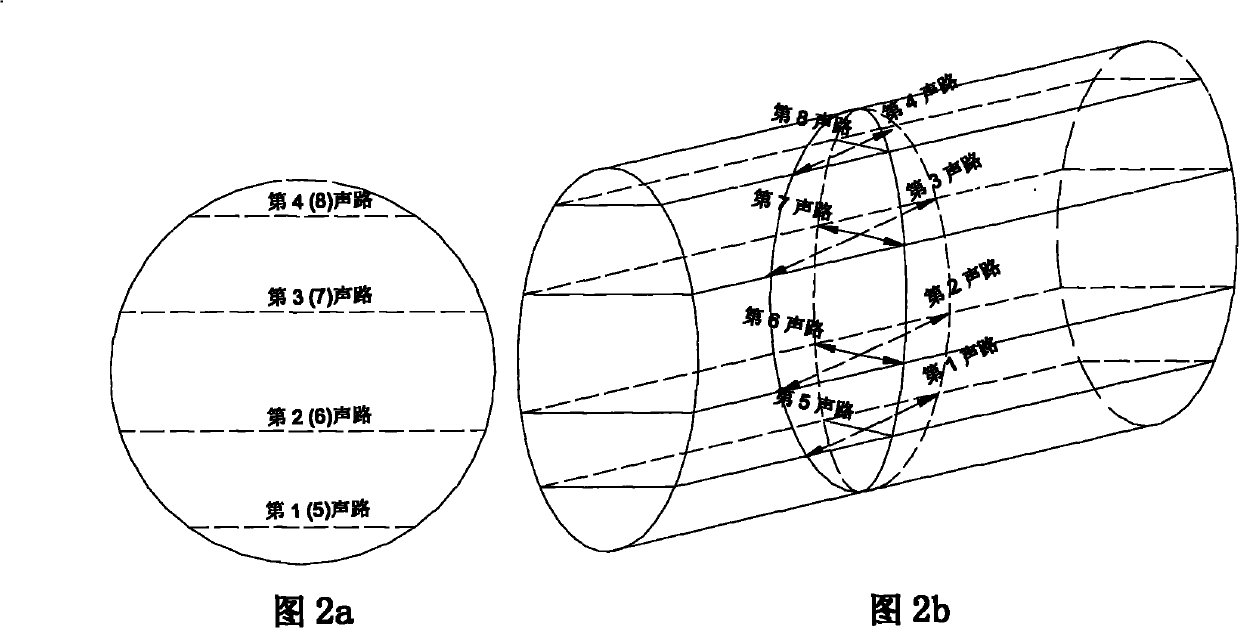

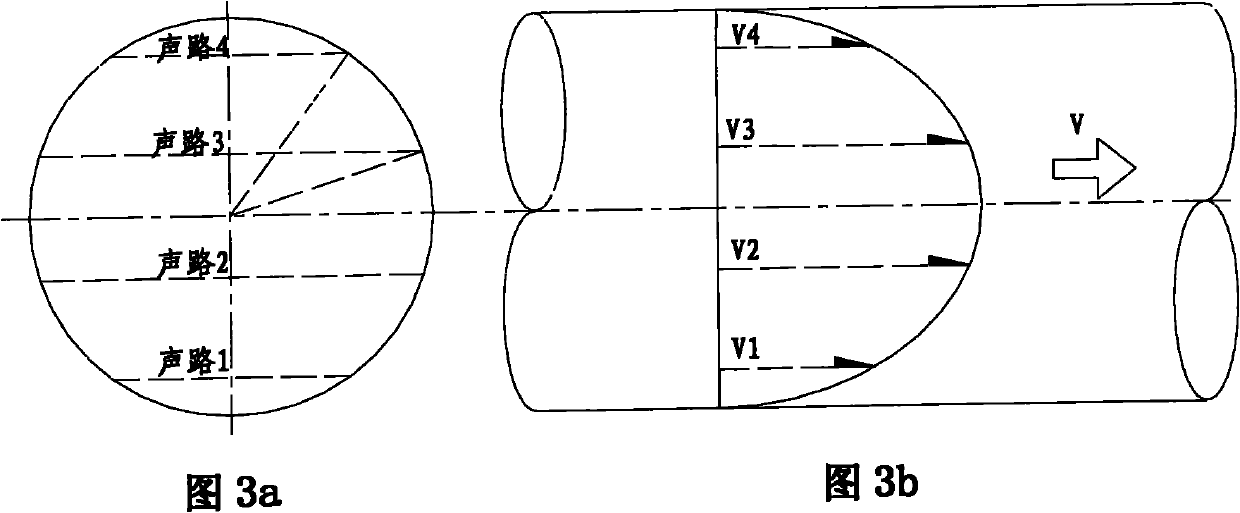

[0028] The following describes the embodiments of the present invention in further detail with reference to the accompanying drawings, but the present embodiments are not used to limit the present invention. All similar methods and similar changes adopted in the present invention should be included in the protection scope of the present invention.

[0029] The method for improving the accuracy of ultrasonic measurement of liquid flow provided by the embodiment of the present invention is characterized by adopting a two-way simultaneous measurement method to eliminate the influence of changes in ultrasonic propagation speed in different liquids on measurement accuracy.

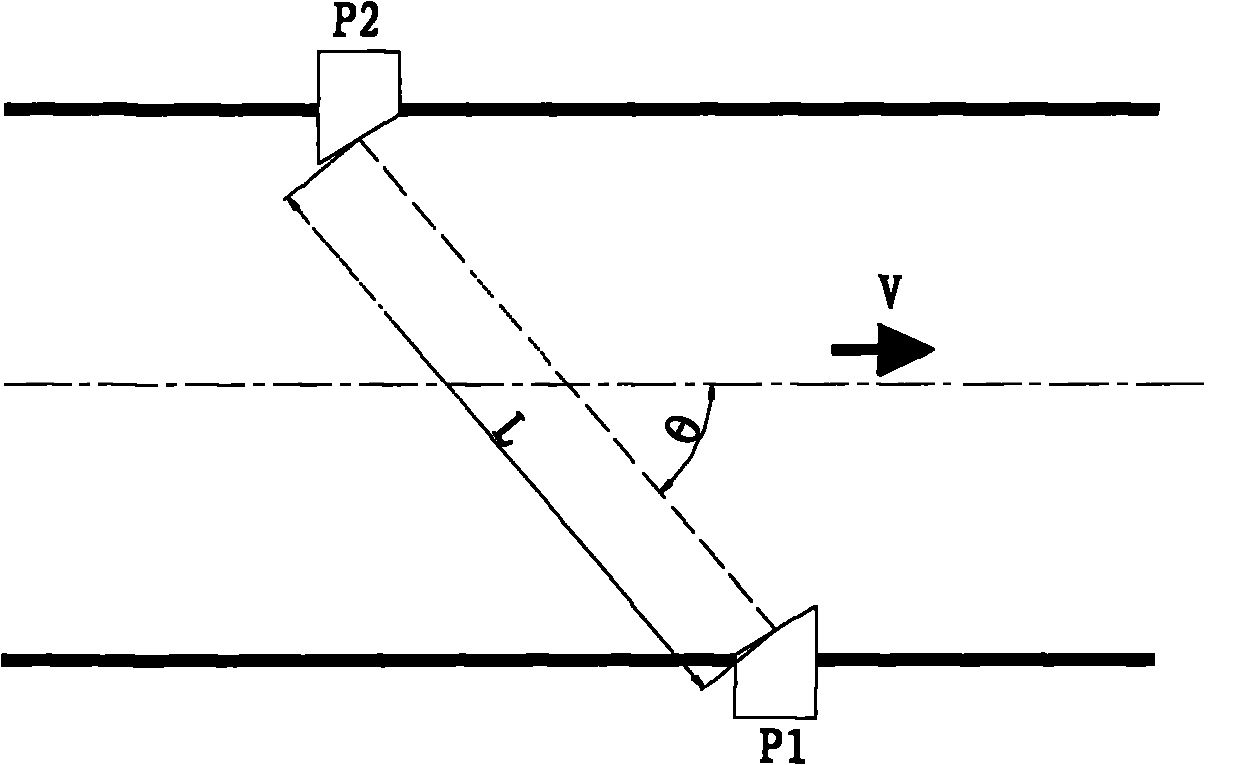

[0030] The basic principle of ultrasonic measurement is that the flow of liquid causes the time of ultrasonic propagation in a specified distance to change, and the speed of liquid flow is calculated according to the change of time. Because the speed of ultrasonic propagation in different liquids is different, for ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com