Natural gas purification system and natural gas purification method for natural gas flow primary standard device

A purification system and standard device technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems that affect the normal operation of the primary standard device of natural gas flow, increase the measurement uncertainty of natural gas flow, increase the flow pressure drop, etc., to achieve Improve the effect of dehydration, improve the accuracy of flow measurement, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

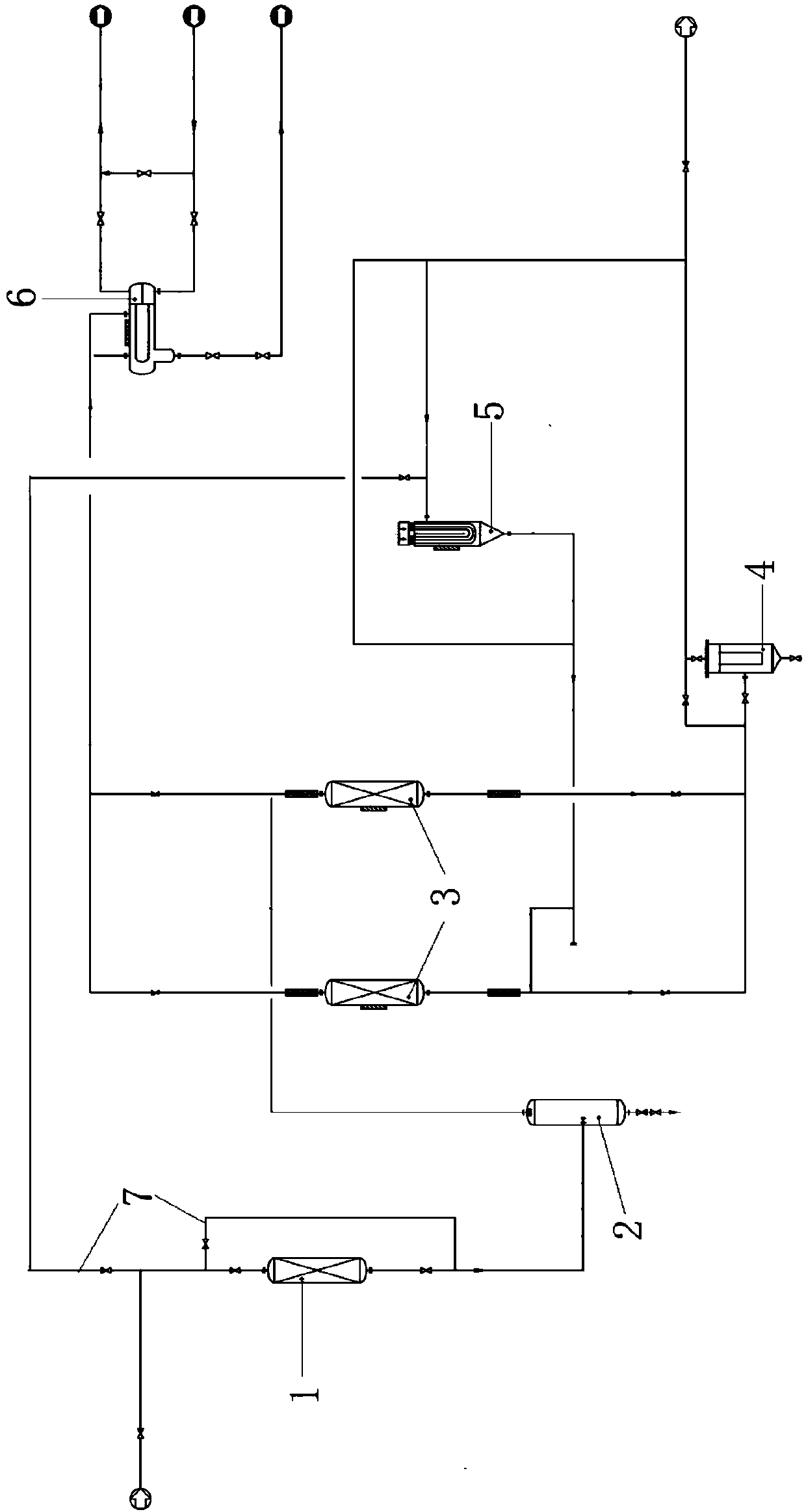

[0046] The embodiment of the present invention provides a natural gas purification system for the primary standard device of natural gas flow, as shown in the attached figure 1 As shown, the natural gas purification system includes: a desulfurization tank 1, a buffer tank 2, a dehydration device 3, and a filter 4 connected in sequence through pipelines; the sulfur in the desulfurized natural gas; the dehydration device 3 is used to pass the desulfurized natural gas from top to bottom to absorb the moisture in the desulfurized natural gas; the filter 4 is used to remove the solid particles in the dehydrated natural gas, and part of the The natural gas after the removal of solid particles is sent to the standard flowmeter of the primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com