Battery aqueous adhesive, and electrode and battery using same

A binder and water-based technology, applied in the field of battery water-based binders, electrodes and batteries, can solve the problems of unstable battery performance and poor adhesion, and achieve strong adhesion, stable performance, and lower battery internal resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

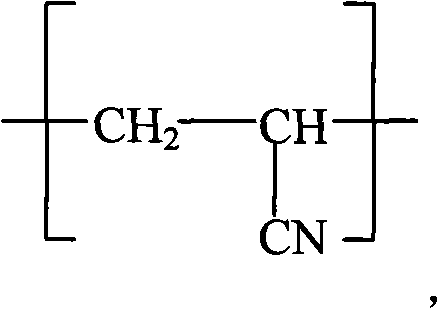

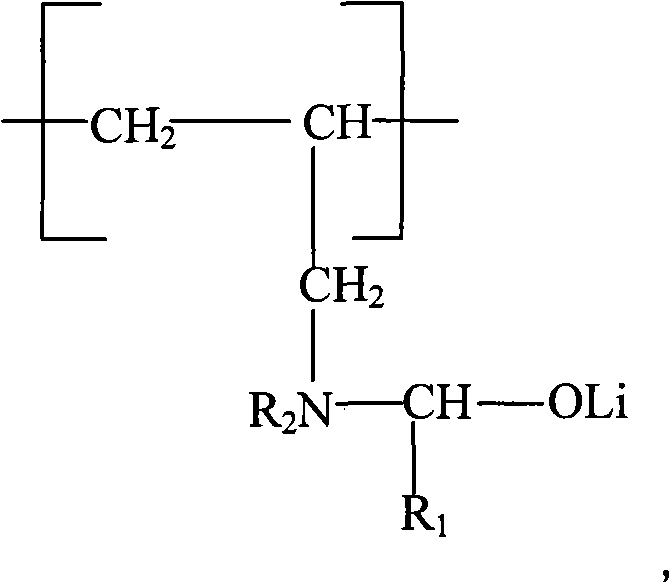

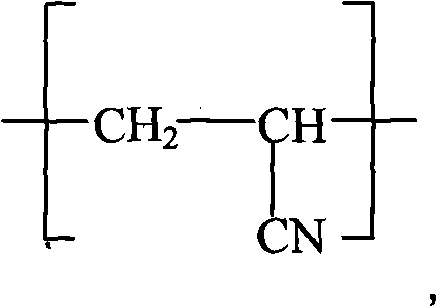

[0029] The preparation method of the branched polyacrylonitrile of the present invention can be prepared by a conventional synthesis method in the art. For example, polyacrylonitrile can be first synthesized by acrylonitrile monomer, and then part of the side nitrile group (-CN) can be reduced to amine group (-CH by chemical reduction method). 2 -NH 2 ), and then substitute at the amine position and initiate condensation reactions, etc.

[0030] Preferably, the specific detailed steps are: placing the polyacrylonitrile homopolymerized by the acrylonitrile monomer in a sealable glass container, stirring at a low speed, and adding external circulating cooling water. At normal temperature, under the protection of anhydrous and oxygen-free helium, an appropriate amount of lithium aluminum hydride was added thereto, and the reaction was carried out for 0.5 hours.

[0031] The product after the reaction is separated and purified, dissolved in slightly hot alcohol, and a small amou...

Embodiment 1

[0042] ① Binder: use branched polyacrylonitrile as the binder, and the R in the branched polyacrylonitrile 1 , R 2 Both are methyl, and their number average molecular weight is 9.8×10 5 , unit A accounts for 90wt%, and unit B accounts for 10wt%.

[0043] ② Preparation of slurry: Disperse the binder in water and stir the solution to make the concentration 10%. Add the conductive agent therein, stir for 8 minutes at a rotating speed of 800 rad / min, and then stir for 30 min at a rotating speed of 2000 rad / min. Then add active material therein, stir for 30min at the rotation speed of 1500rad / min, and then stir for 150min at the rotation speed of 2000rad / min.

[0044] When preparing the positive electrode slurry, the active material of the positive electrode is lithium iron cobalt phosphate, and the conductive agent is a mixture of Super-P and KS-6 graphite.

[0045] When preparing the negative electrode slurry, graphite is used as the negative electrode active material, and a ...

Embodiment 2

[0049] The difference from Example 1 is that the number average molecular weight of the binder is 5×10 3 branched polyacrylonitrile.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap