Method for forming spigot end of large-diameter socket and spigot type reinforcement concrete pipe

A molding method and socket-type technology, which is applied in reinforced molding, ceramic molding machines, manufacturing tools, etc., can solve the problems of easy deformation of semi-circular molds, lower precision of sockets and sockets, unusable molds, etc., and achieve the effect of improving molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

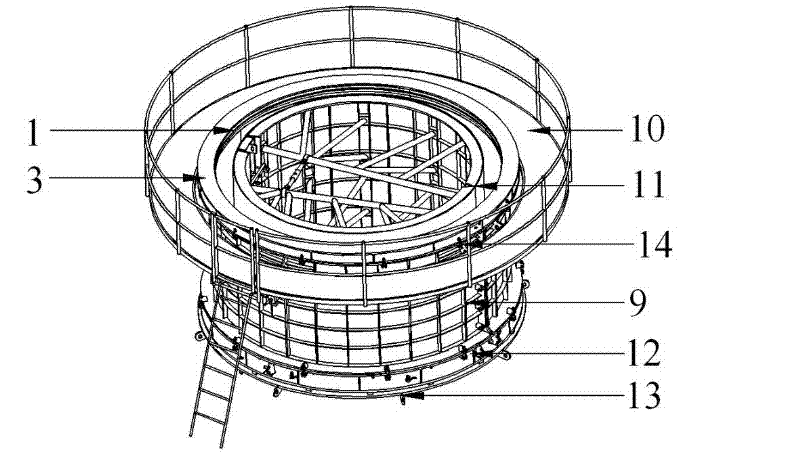

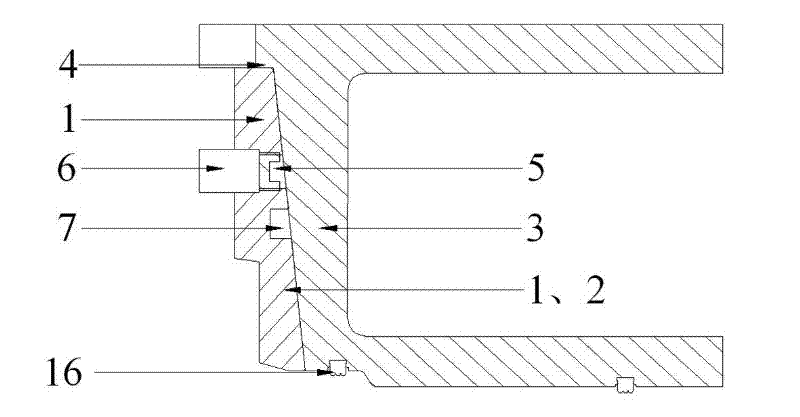

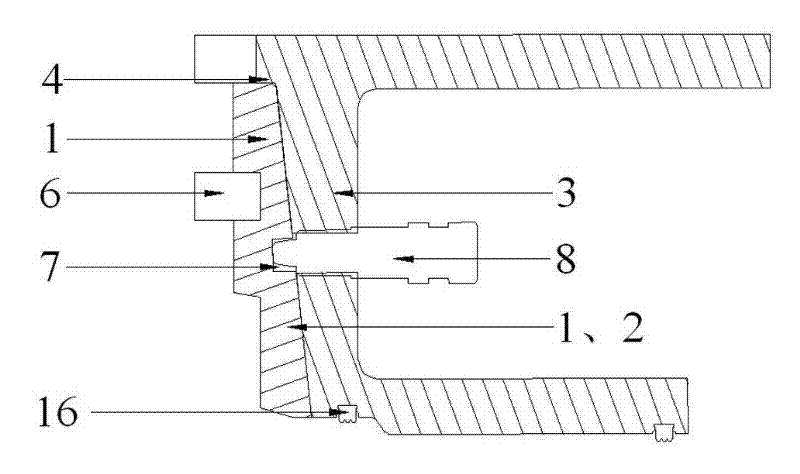

[0025] Such as Figure 1 to Figure 4 As shown, the total reference numerals 1-16 represent respectively: forming mold 1, half mold 2, positioning mold 3, flange 4, screw hole 5, steel ring 6, groove 7, clip 8, middle mold 9, working platform 10. Inner mold 11, lower mold 12, bottom mold 13, closing bolt 14, positioning pin 15, rubber ring 16.

[0026] see figure 1 As shown, the reinforced concrete pipe mold adopted in the present invention is mainly composed of bottom mold 13, lower mold 12, middle mold 9, upper mold and inner mold 11, wherein the upper mold is a pouring mold for the outer surface of the socket end, and the middle mold 9 is the casting mold for the outer surface of the reinforced concrete pipe body, the lower mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com