Automatic glue-dispersion chip mounting machine

An automatic dispensing and placement machine technology, applied in mechanical equipment, connecting components, devices for coating liquid on surfaces, etc., can solve problems such as low overall efficiency, and achieve the effect of saving labor, convenient operation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

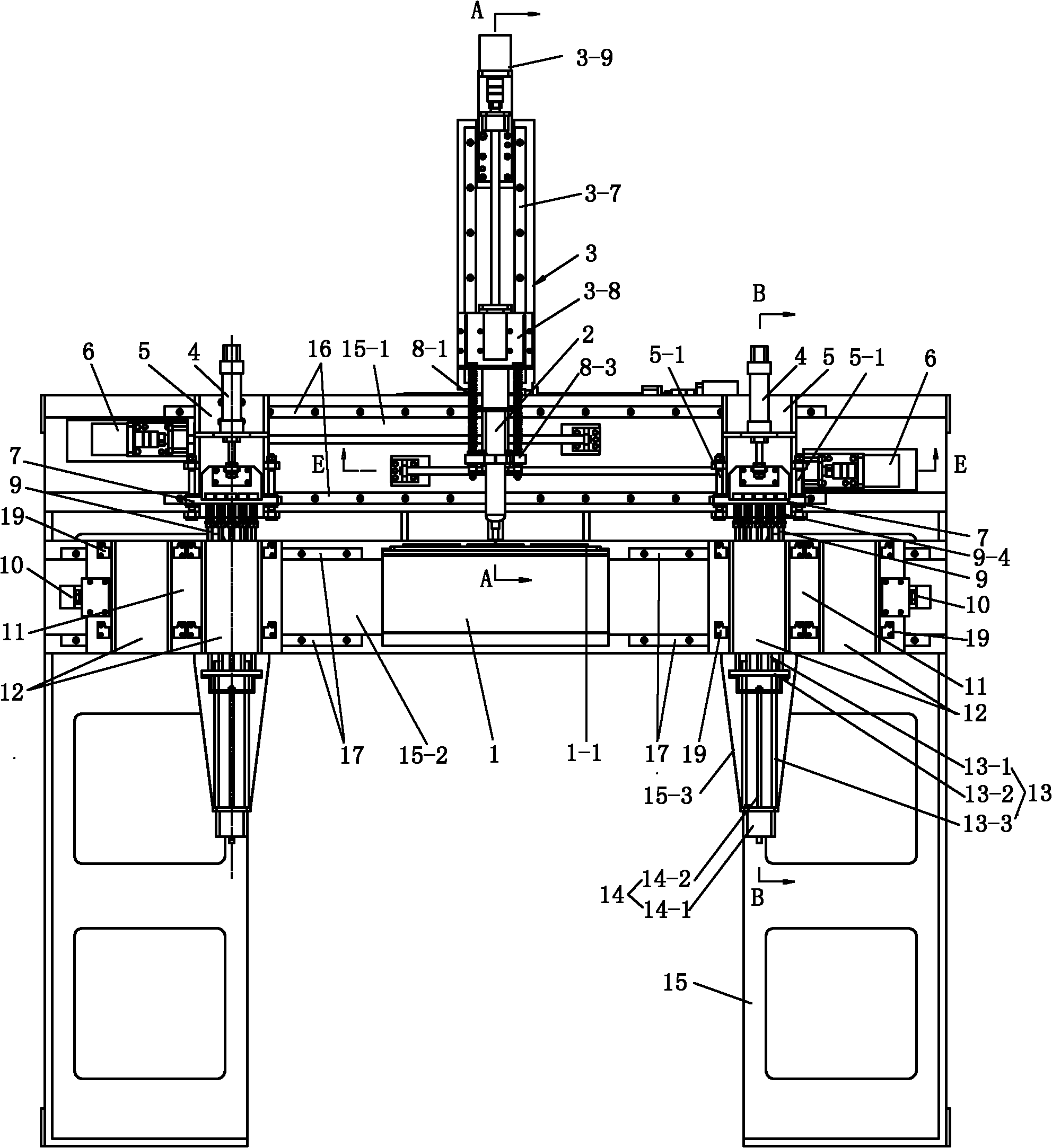

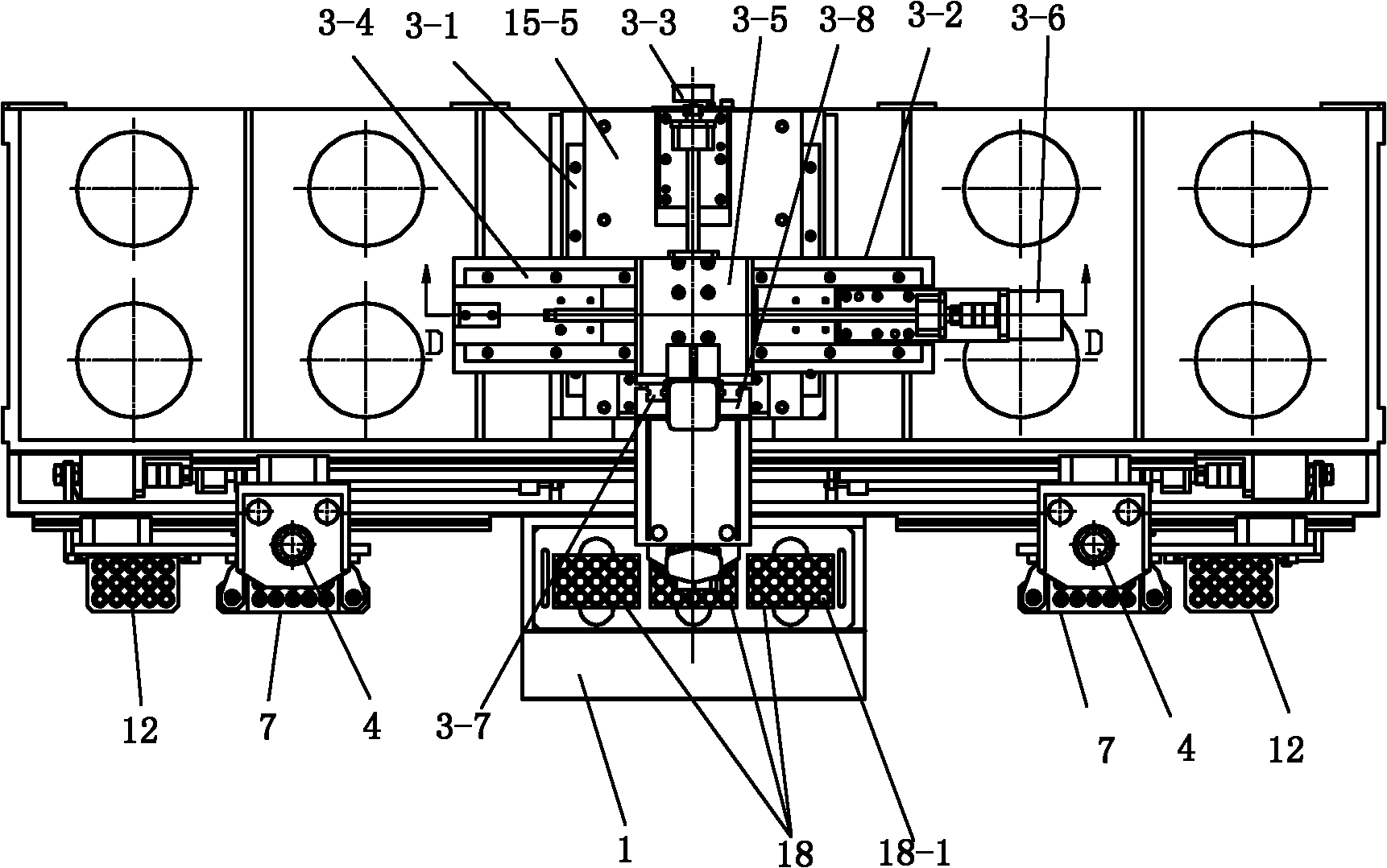

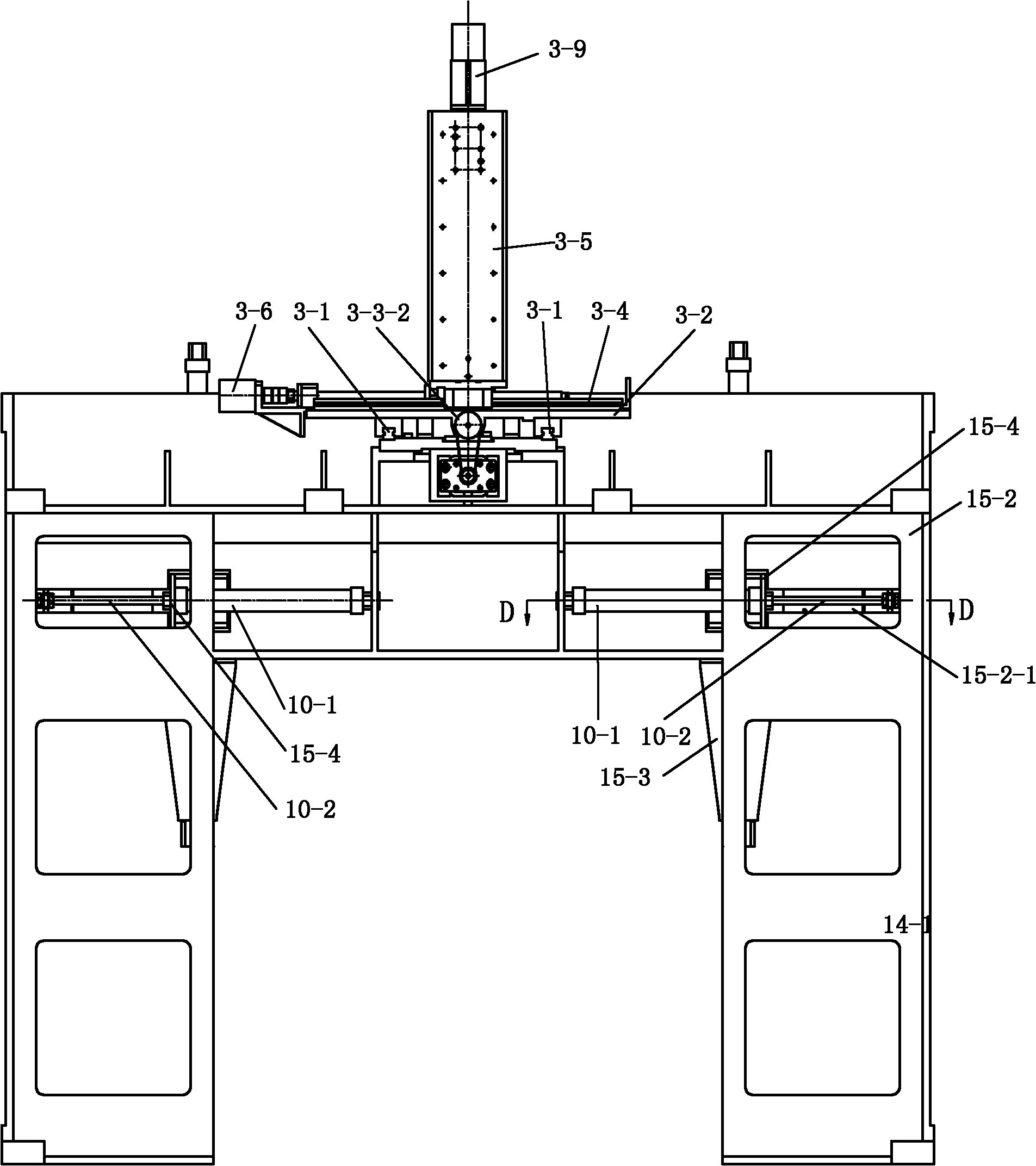

[0028] see Figure 1 to Figure 4 , The automatic dispensing and placement machine shown includes a frame 15. The frame 15 has upper and lower front walls 15-1 and 15-2. The lower front wall 15-2 of the frame is fixed with a workbench 1, a workbench 1. There is a numerical control system operation panel 1-1, and a glue dispensing device supported by the frame 15 is arranged above the workbench 1. The glue dispensing device includes a glue cylinder 2, a glue cylinder 2 that drives the glue cylinder 2 to move three-dimensionally relative to the workbench 1 The device 3 and the dispensing volume control assembly connected with the glue cylinder 2.

[0029] see Figure 1 to Figure 5 , Figure 8 , The dispensing driving device 3 includes a front and rear dispensing guide 3-1, a sliding bottom plate 3-2, a front and rear dispensing driving mechanism 3-3, a left and right dispensing guide 3-4, a sliding post 3-5, left and right Dispensing drive mechanism 3-6, up and down dispensing guid...

Embodiment 2

[0046] see Picture 10 In this embodiment, the lower part of the front wall 15-1 of the rack and the two sides of the workbench 1 can be exchanged and connected to a material box 12. Compared with the embodiment 1, the lower guide rail 17 and the lower sliding seat 11 are not provided. And the lower sliding seat drive mechanism 10, simplifying the structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com