Microscopic slide automatic feeding device

An automatic supply and glass slide technology, which is applied in microscopes, optics, instruments, etc., can solve the problems of complex and cumbersome mechanisms, glass slide damage, and increased equipment volume, and achieve high precision of microscope inspection, accuracy guarantee, Guaranteed continuity of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable the public to fully understand the technical essence and beneficial effects of the present invention, the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a limitation to the technical solution. Changes in form rather than in substance should be regarded as the protection scope of the present invention.

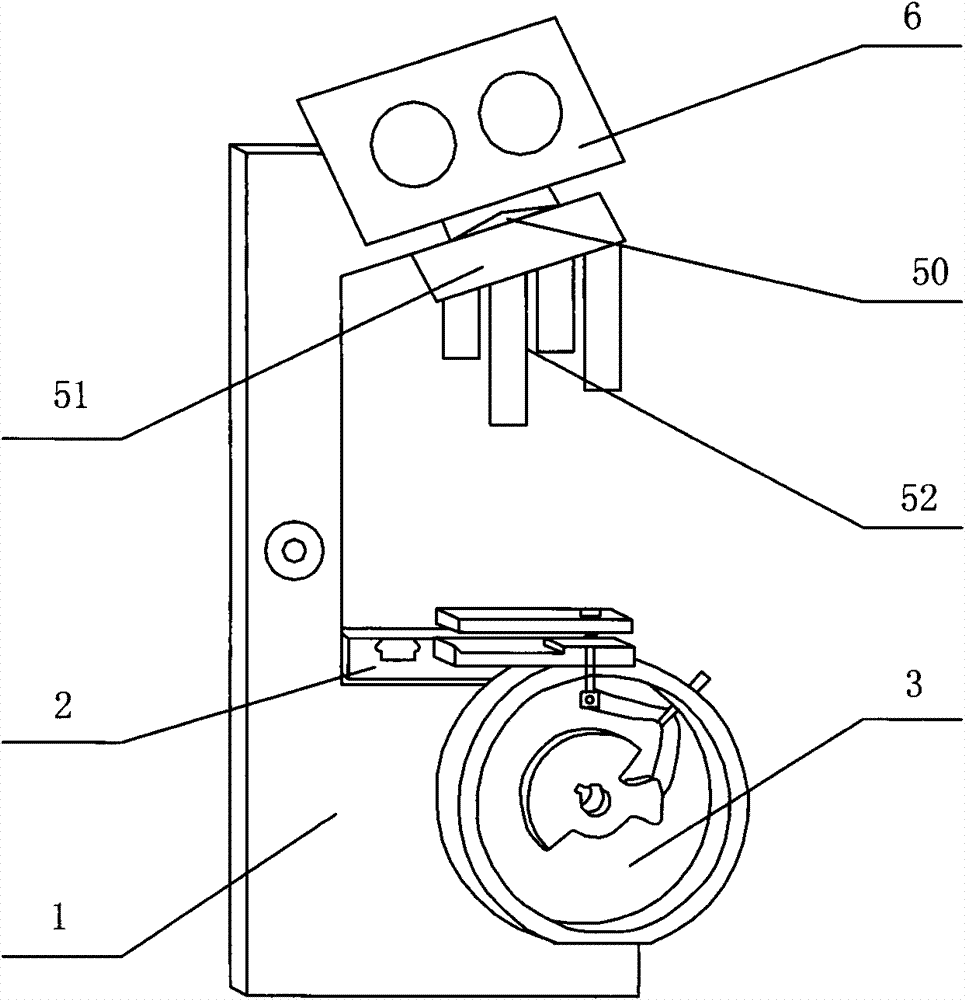

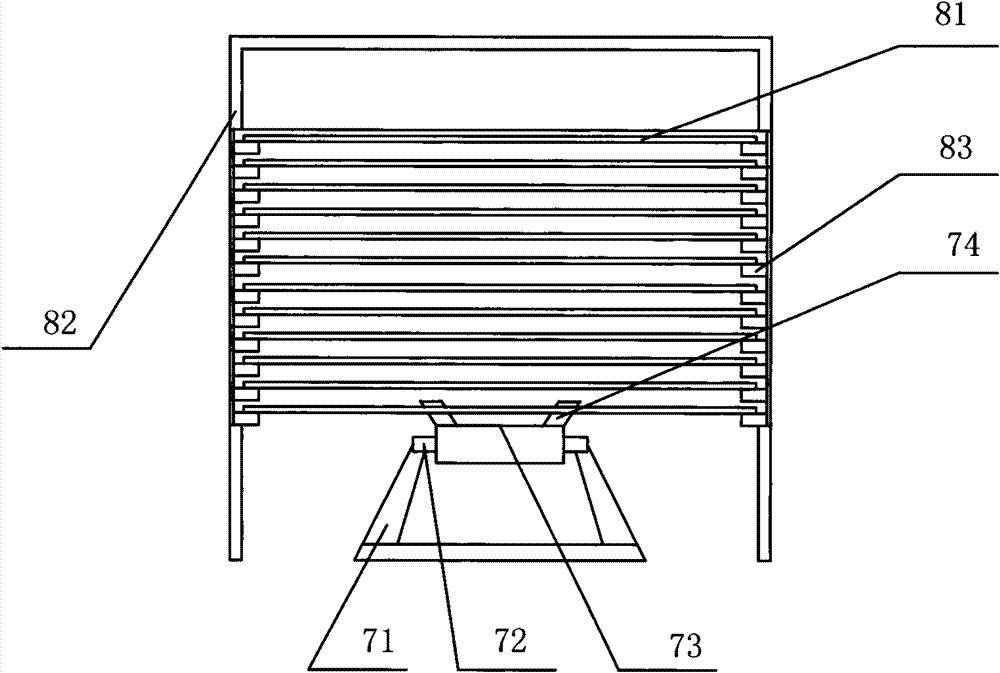

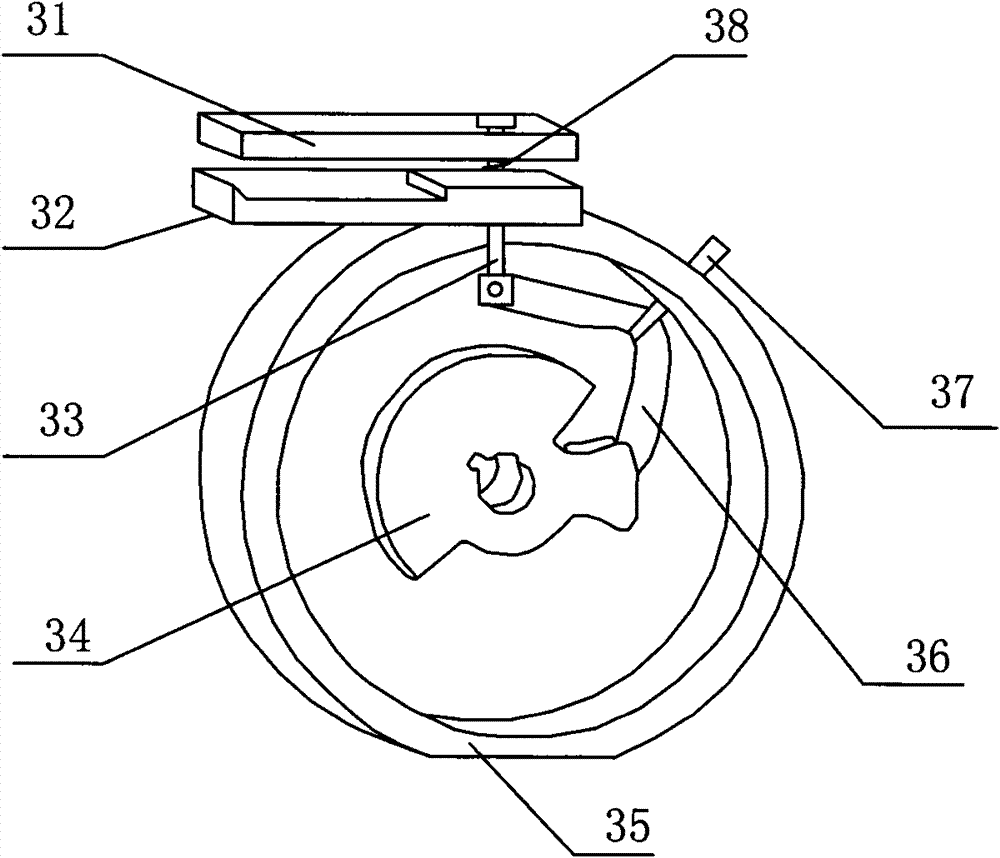

[0030] Such as Figures 1 to 7 As shown, the automatic feeding device for microscope slides of the present invention includes a frame 1, a microscope platform 2, a slide pushing device for transporting the slides 81 in the magazine 82 by using a conveyor belt 73, and clamping and holding the slides. The glass slide horizontal moving clamping device for the slide 81 to move horizontally on the microscopic platform 2, and the slide loading and unloading device 3 for transferring the slide glass 81 between the slide pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com