Patents

Literature

47results about How to "Not fall off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

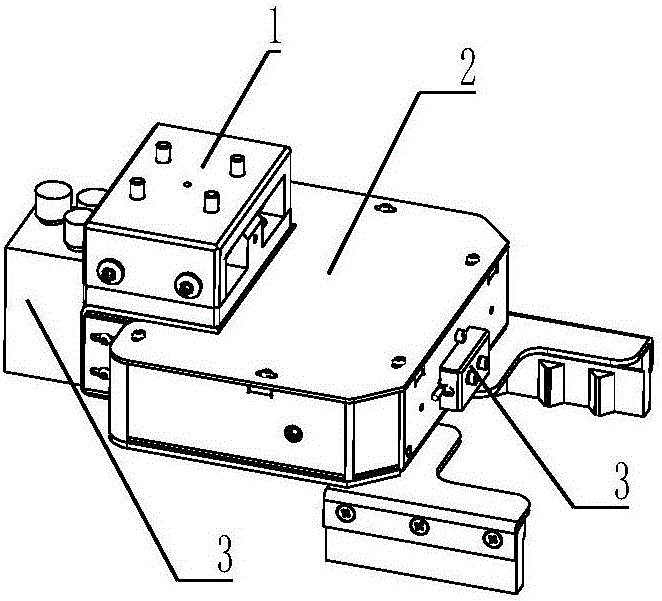

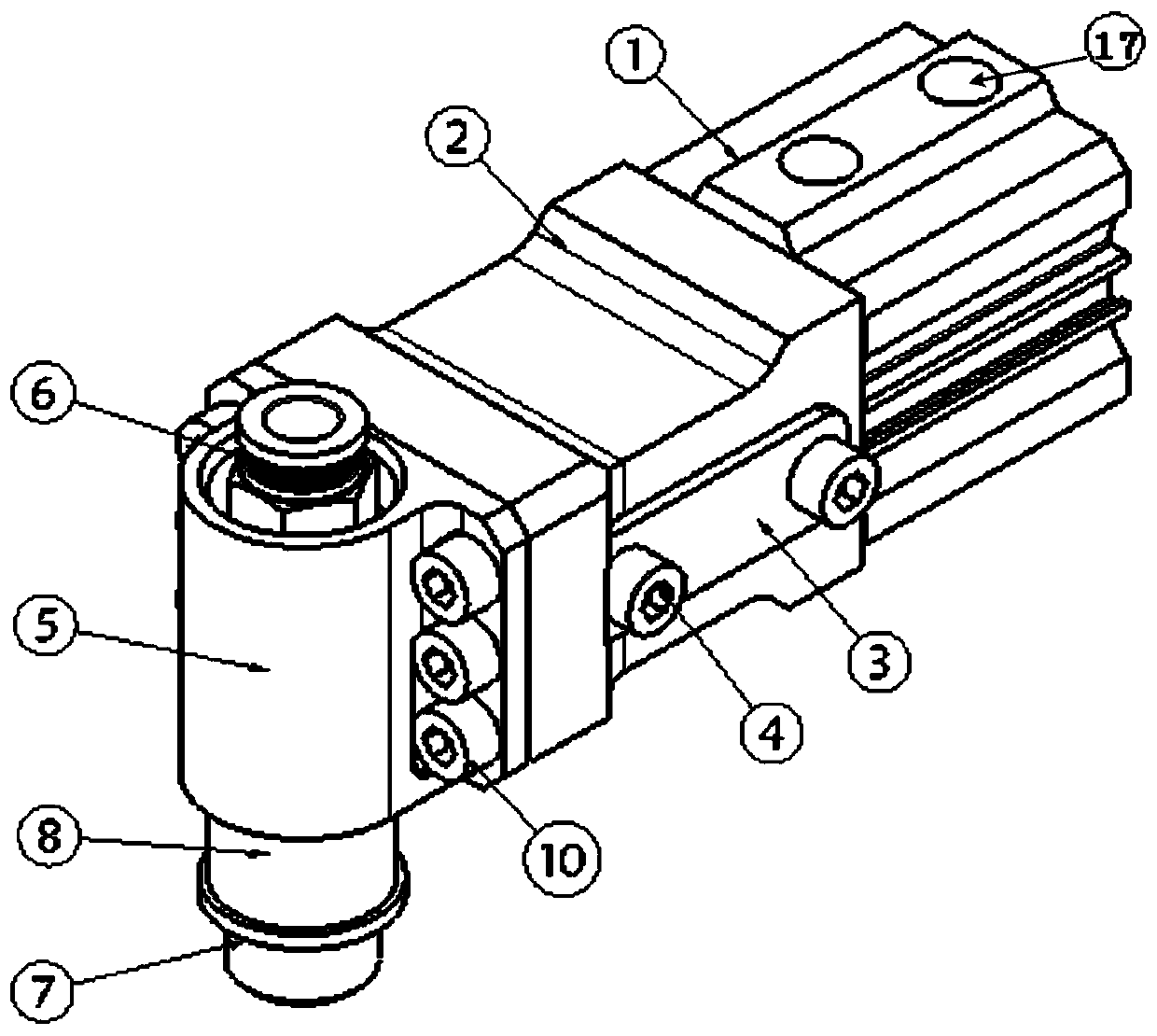

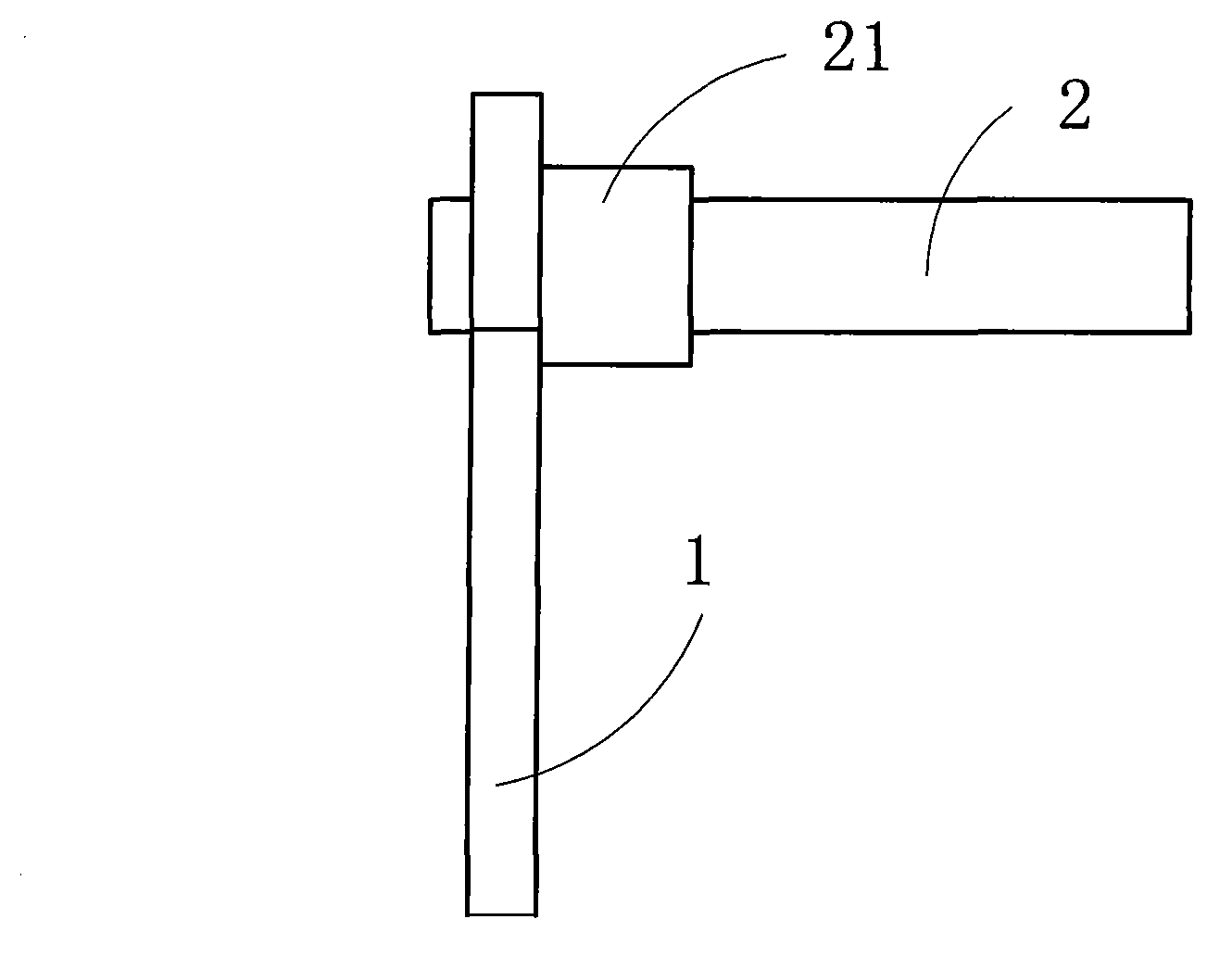

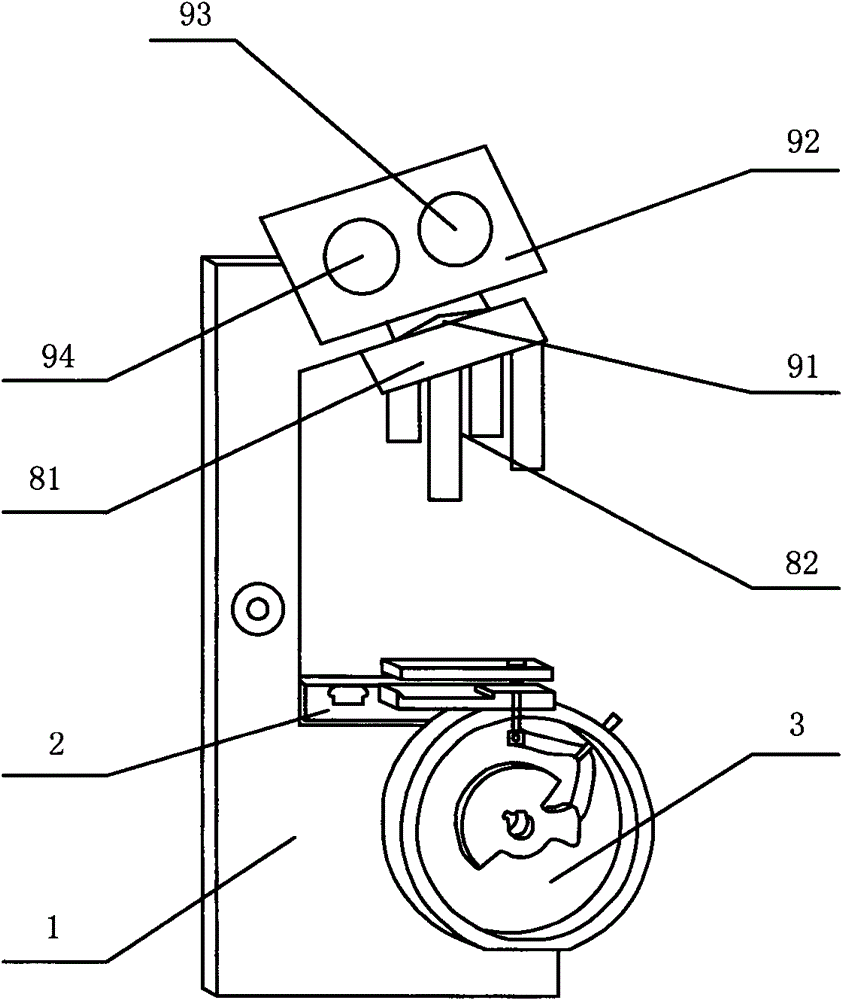

Self-locking material clamping device with buffer

The invention relates to a self-locking material clamping device with a buffer. The self-locking material clamping device comprises an electric clamping jaw, a spring buffer mechanism and a measurement element, the electric clamping jaw comprises a mounting plate, and two opposite grippers and a driving component driving the grippers to move face to face or back to back are arranged on the mounting plate; the spring buffer mechanism comprises a connecting block and a first slider in sliding connection with the connecting block and in connection with the mounting plate, two parallel guide shafts are connected to the connecting block, a perpendicular protrusion is arranged in the middle of the first slider, the protrusion sleeves the middles of the two guide shafts, and the guide shafts are sleeved with springs butting against the side wall of the connecting block and the side wall of the protrusion; the measurement element comprises a photoelectric sensor, a photoelectric switch and a visual sensor, the photoelectric sensor which is located between the two grippers is used for detecting whether materials are clamped by the electric clamping jaw or not, the electric clamping jaw is used for limiting when the grippers are closed and opened, and the visual sensor is used for identifying a positioning piece fixed to a material platform so as to acquire relative position information of the materials relative to the grippers.

Owner:SUZHOU XINYOUHUA INVESTMENT ADVISOR CO LTD

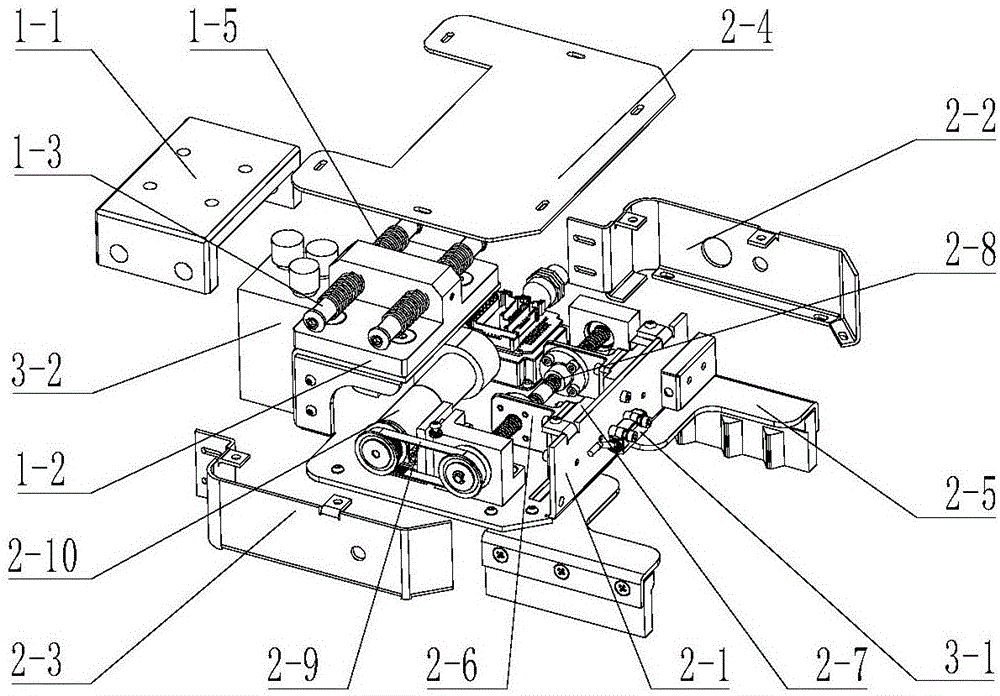

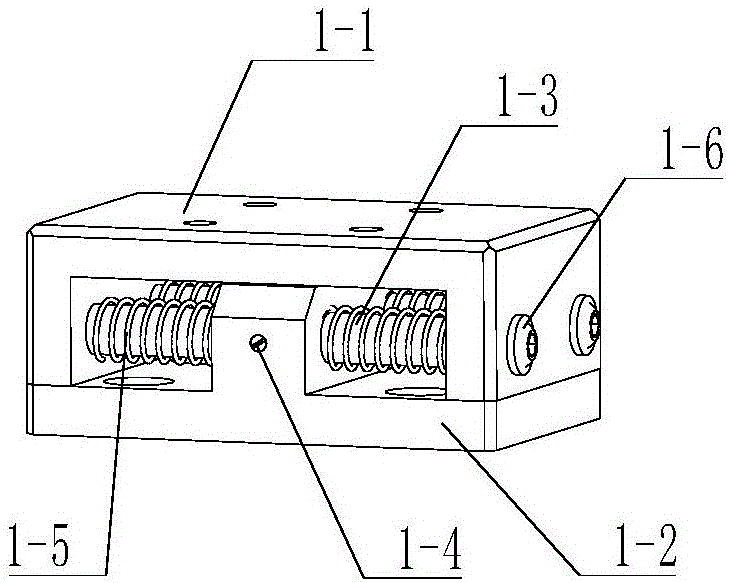

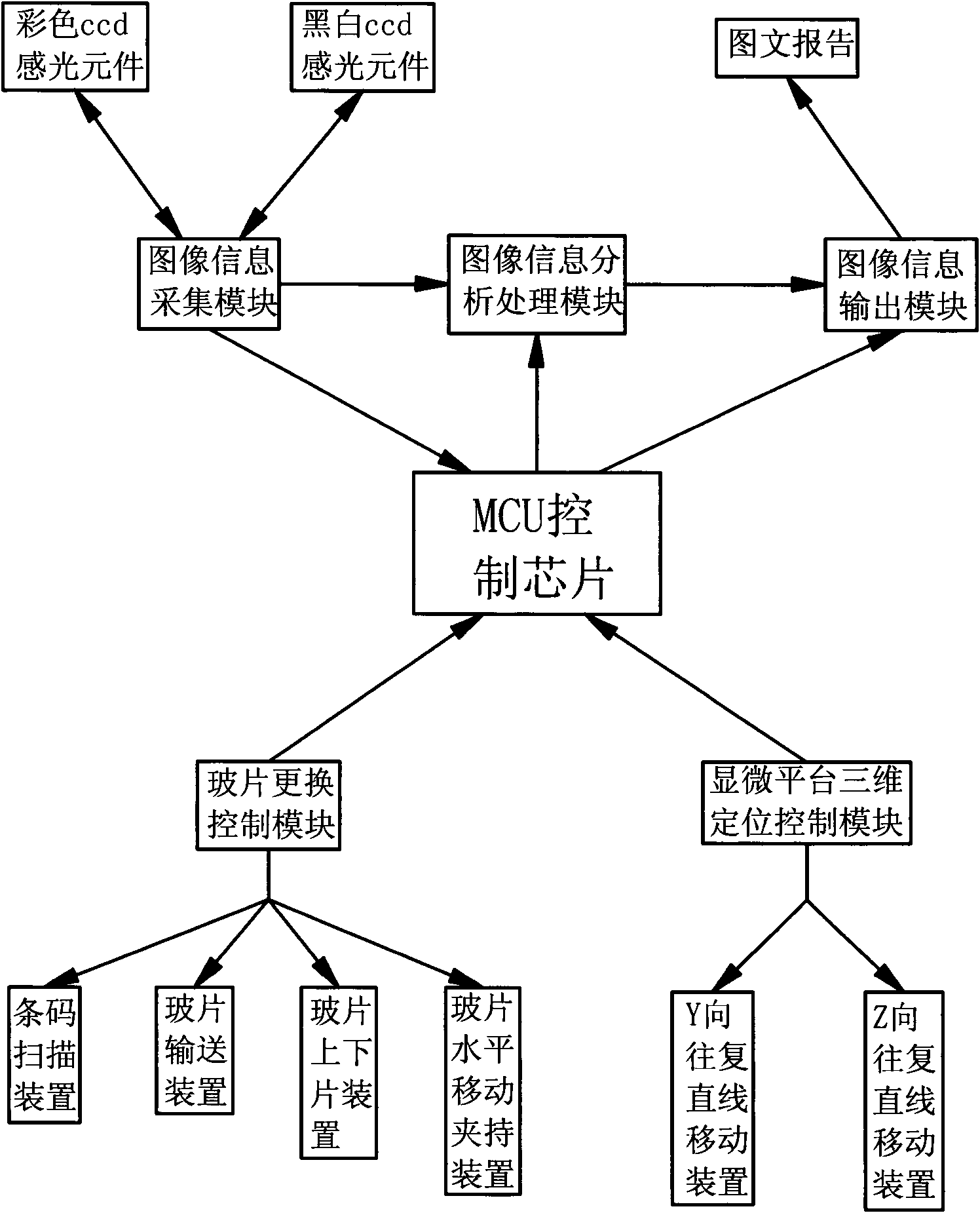

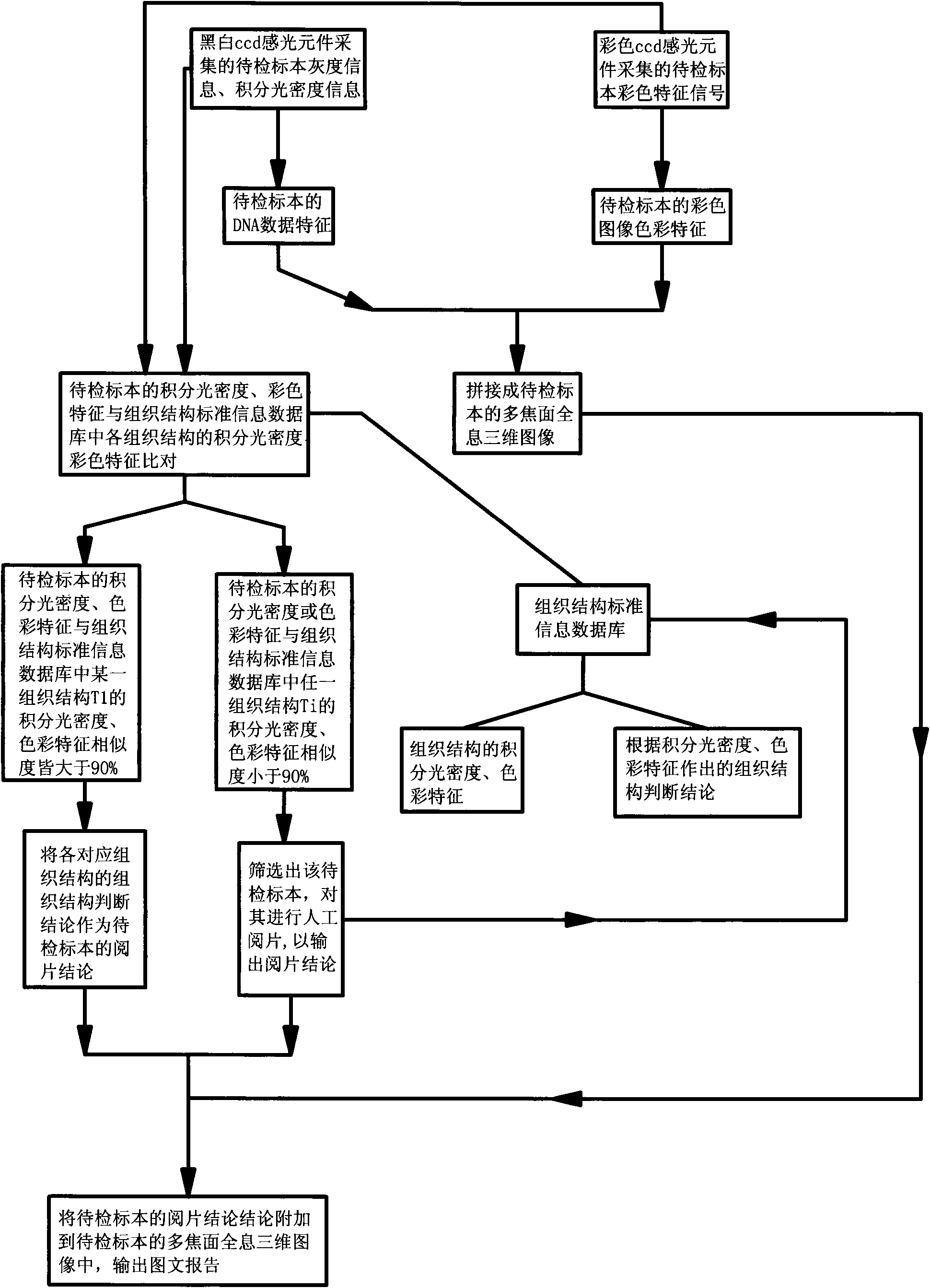

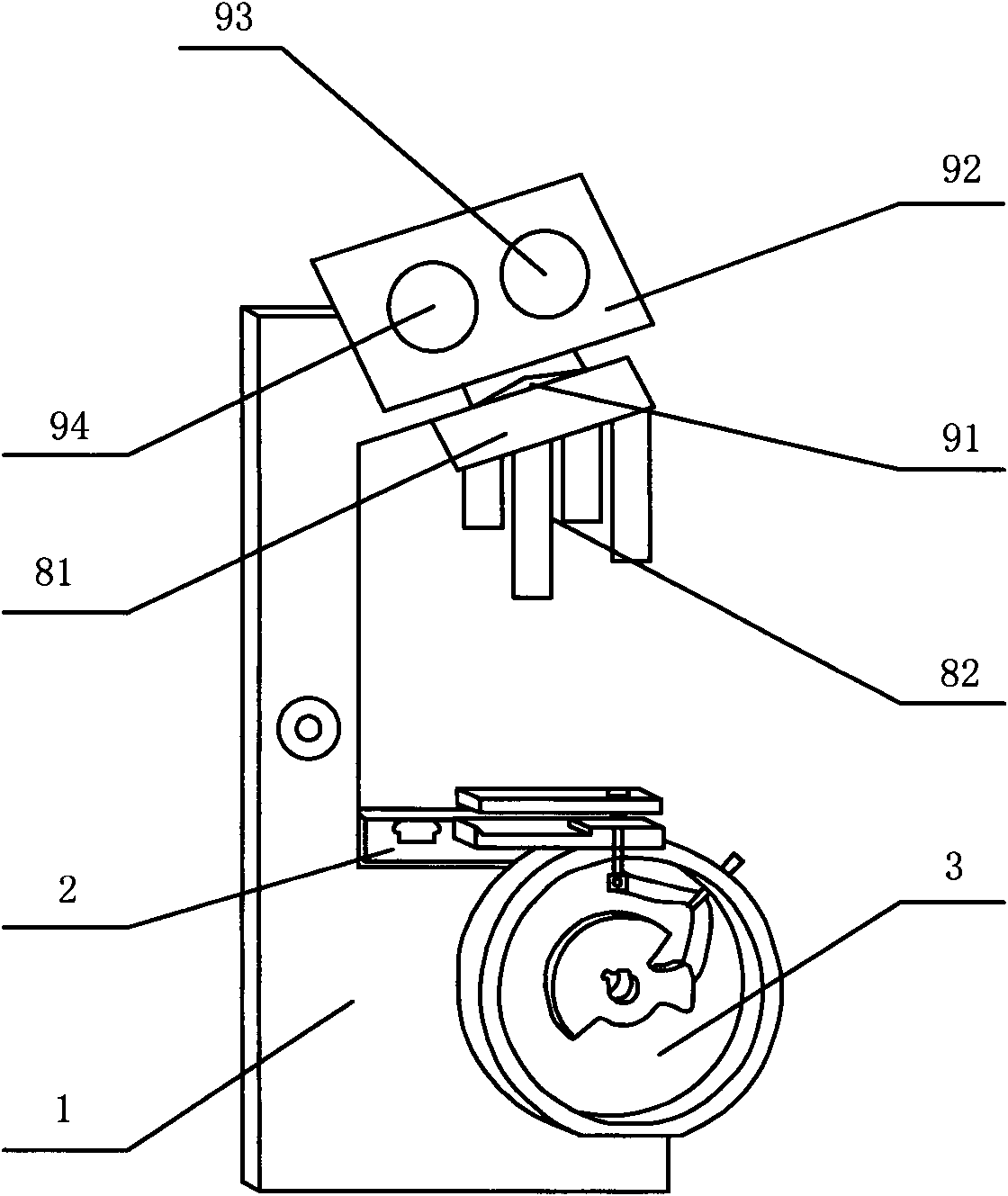

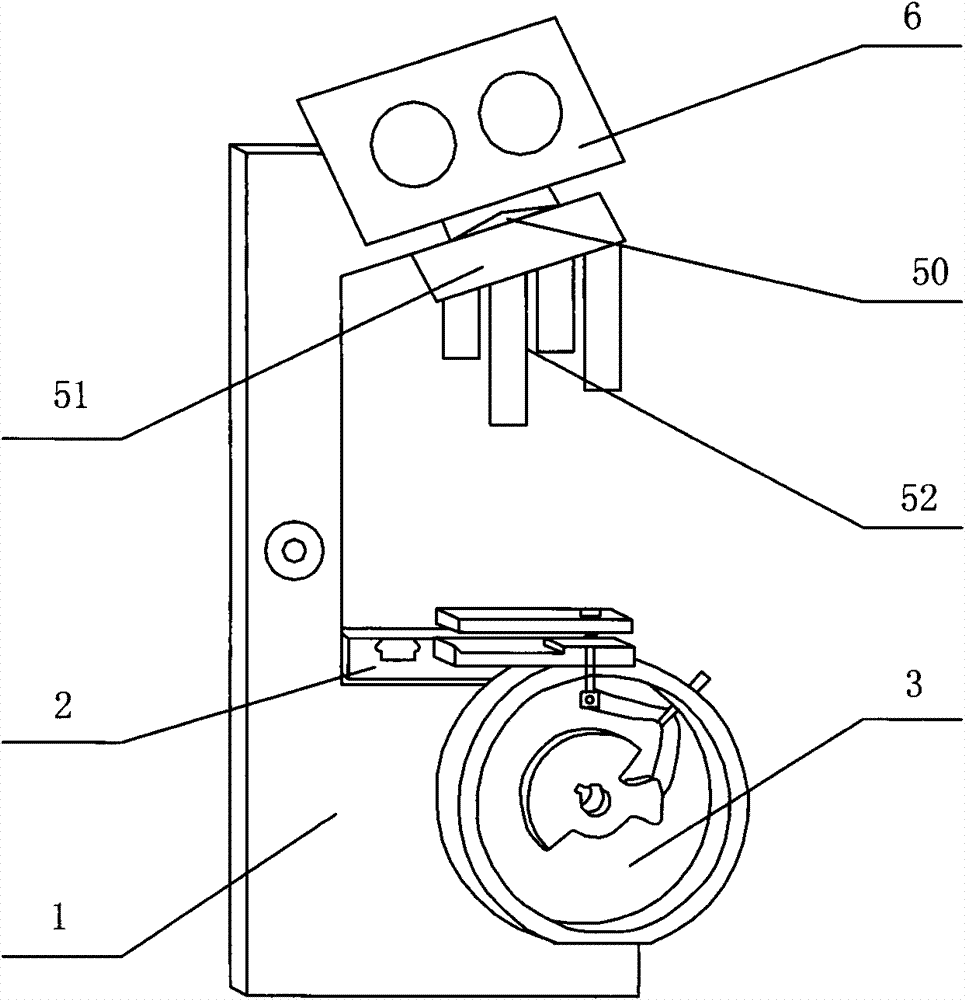

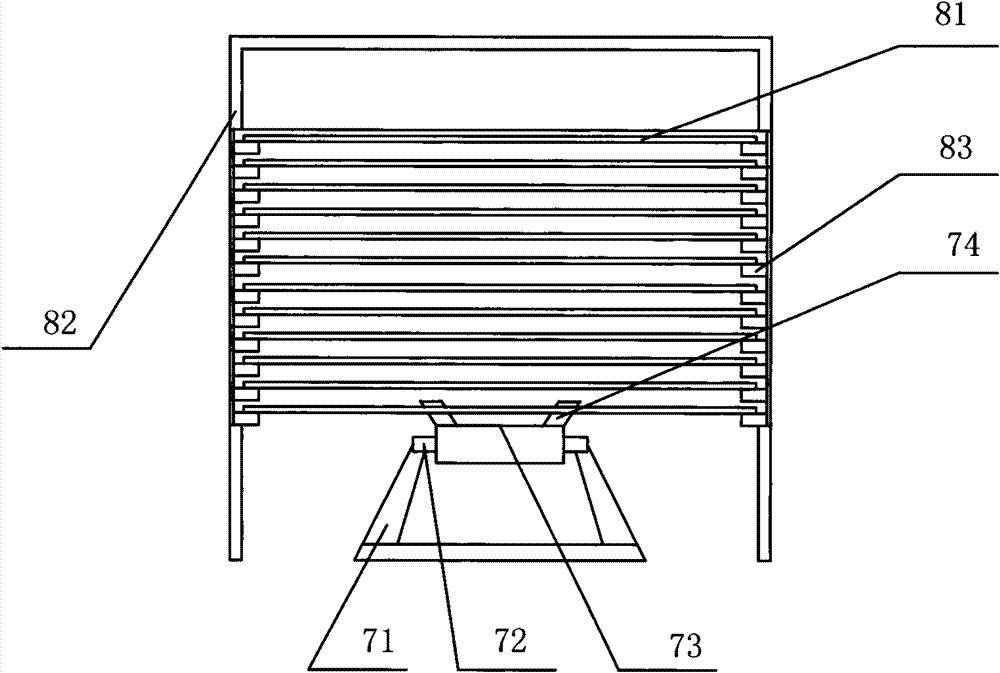

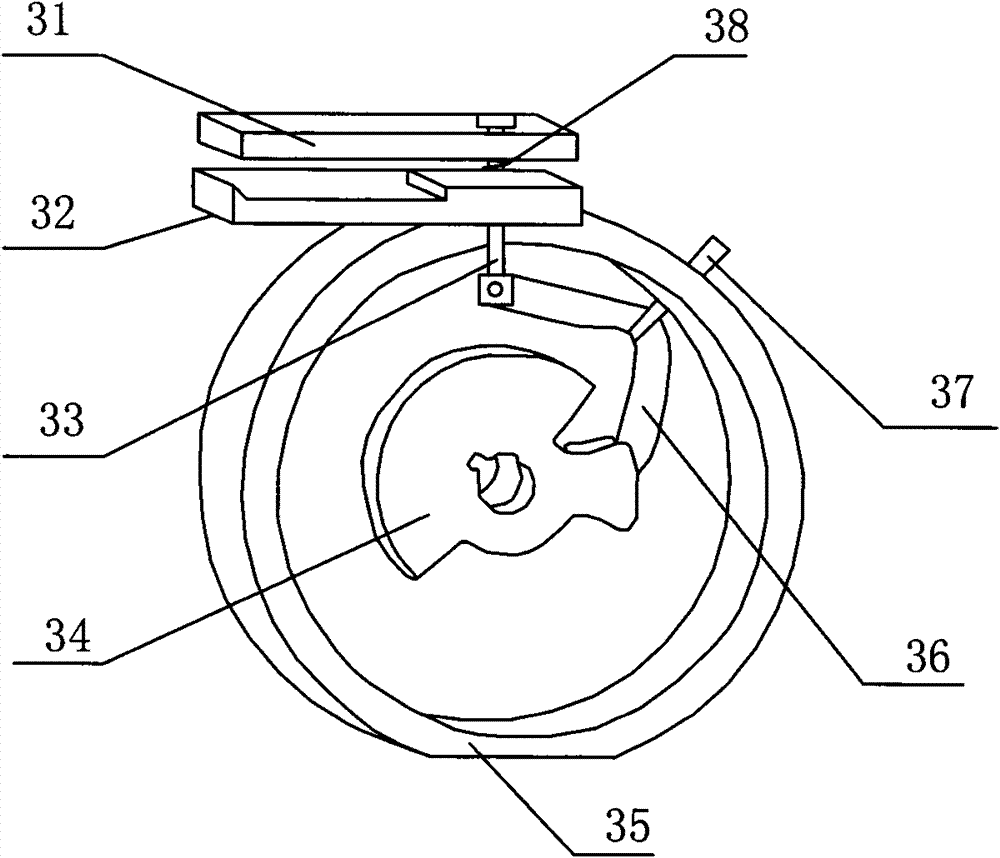

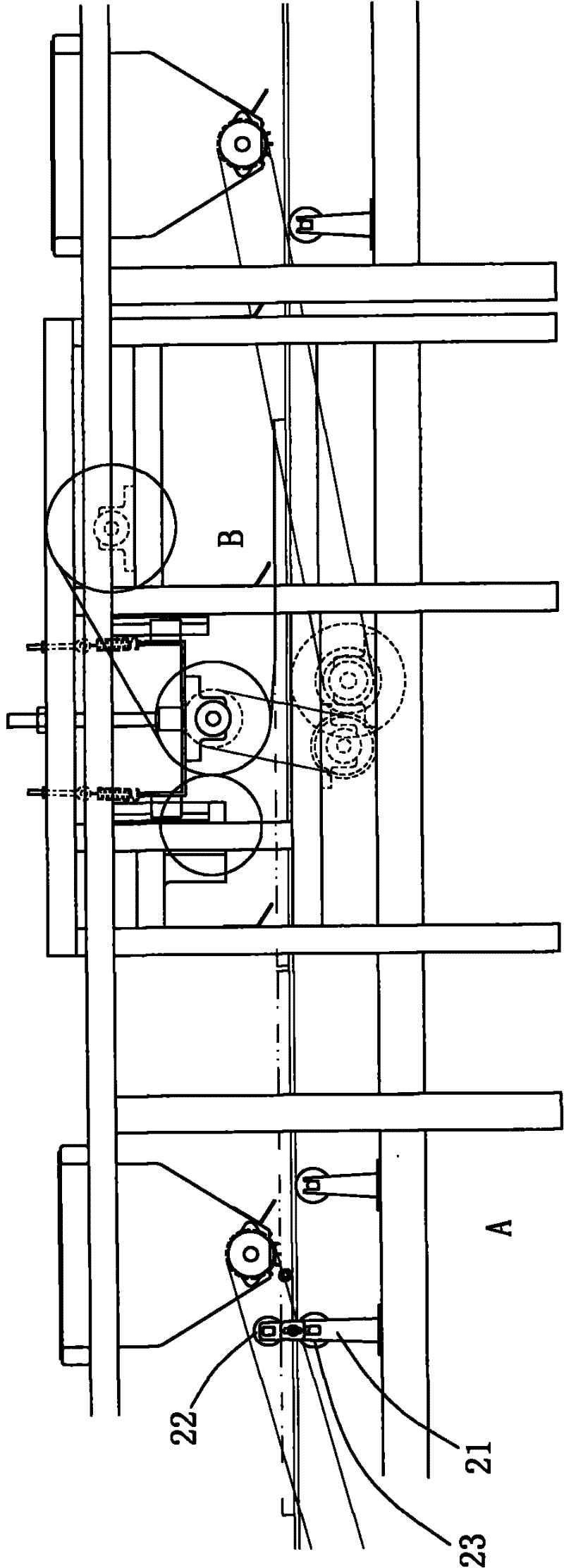

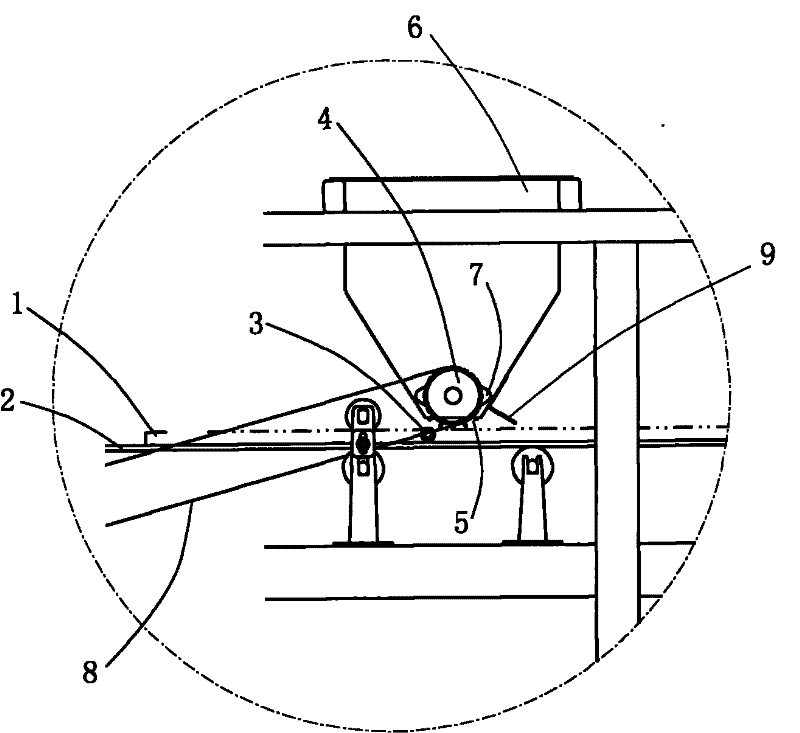

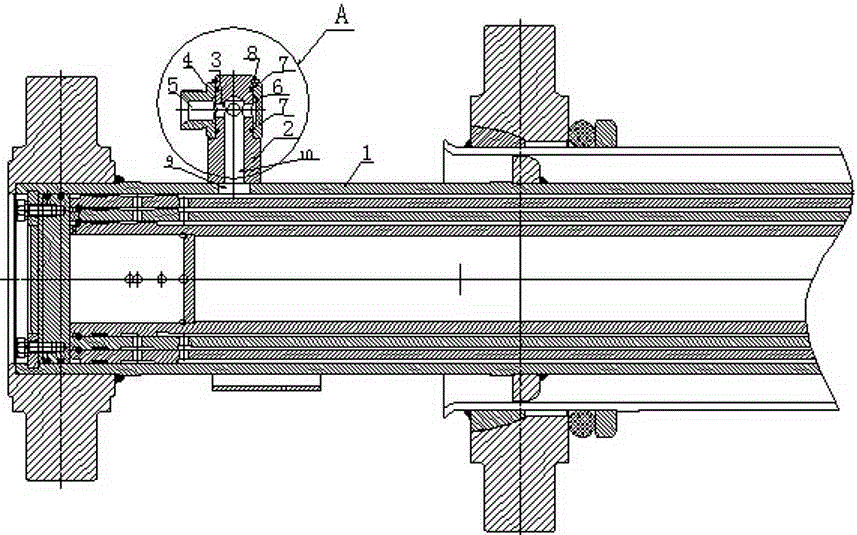

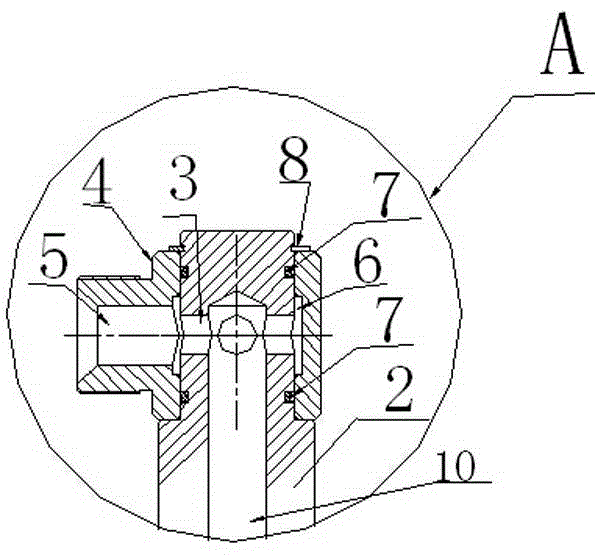

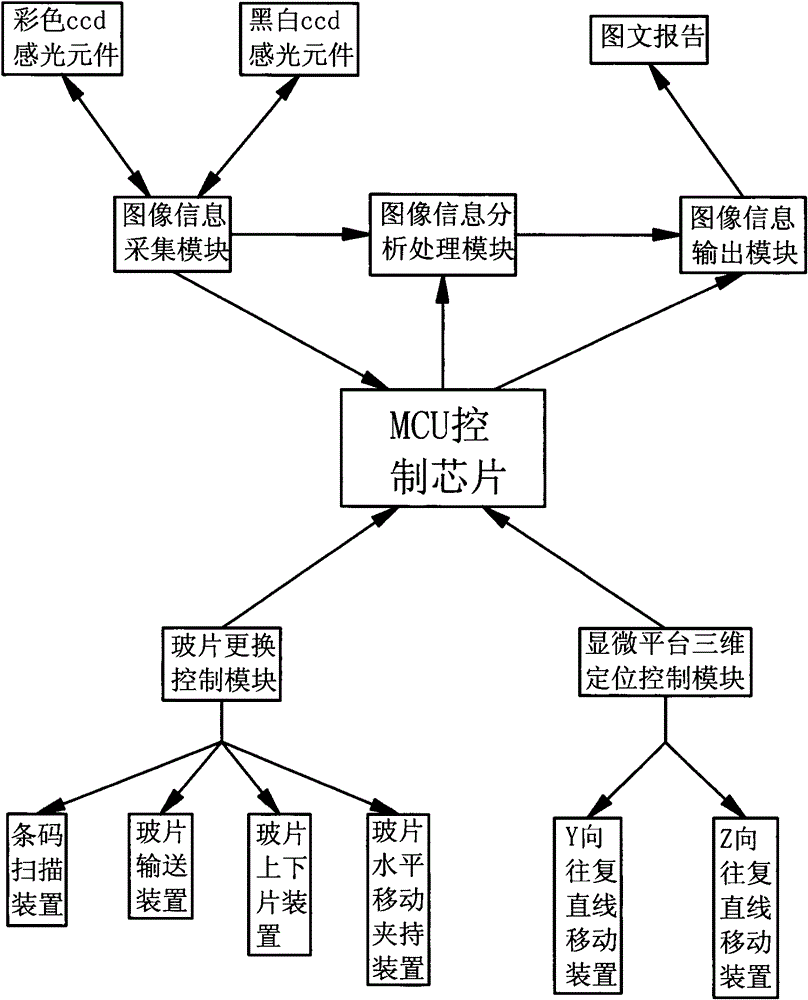

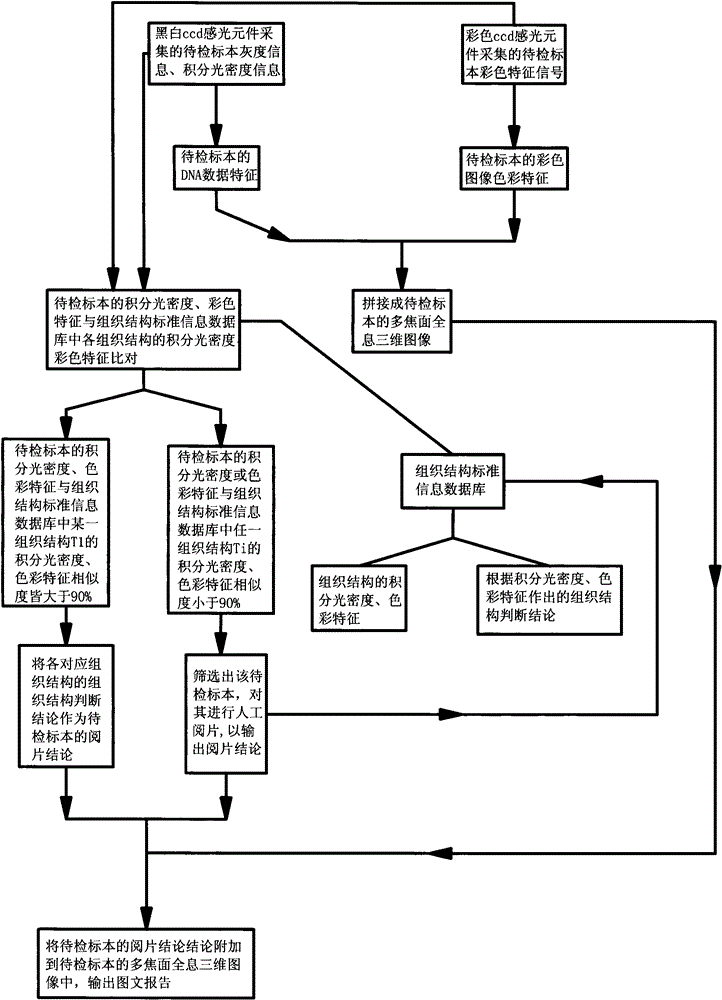

Full-automatic double-ccd photosensitive element digital microscope

ActiveCN102122066ATo achieve the purpose of intelligent screeningGuaranteed effectMicroscopesDigital imageOptical density

The invention discloses a full-automatic double-ccd (charge-coupled device) photosensitive element digital microscope, which is used for acquiring specimen image information by synchronously using a colored ccd photosensitive element and a black-and-white ccd photosensitive element so as to obtain a multifocal plane holographic three-dimensional image, synchronously outputting a specimen reading result according to nucleus integral optical density acquired by the black-and-white ccd photosensitive element, and finally outputting a specimen picture and text report. Additionally, the full-automatic double-ccd photosensitive element digital microscope comprises a slide uploading and unloading device and a horizontal migration clamping device for automatically changing the specimen slide, and then, the slide is located in three dimensions through a three-dimensional frame, so that the colored ccd photosensitive element and the black-and-white ccd photosensitive element can conveniently acquire the image information of the specimen. Thus, the full-automatic double-ccd photosensitive element digital microscope can be used for not only performing morphological observation on the specimen, but also taking digital images for a dyed tissue section so as to form the multi-focal plane holographic three-dimensional image, so that all the information of the cell can be observed in multiple layers and multiple focal planes, and accuracy of early diagnosis is greatly improved.

Owner:湖南港湾科学仪器有限公司

Method for planting esoderma/endothelial cell on inner surface of artificial blood vessel

InactiveCN1559360AImprove adhesionInhibit hyperproliferationMicroorganismsGenetic material ingredientsBlood vessel featureFluid shear

A method for implanting the endothelial cells on the inner surface of artificial blood vessel features that a biomechanical method is used, that is, an external pulsive fluid shearing force increased step by step acts on the planted endothelial cells to make them be attached well on the inner surface of artificial blood vessel in advance.

Owner:CHONGQING UNIV

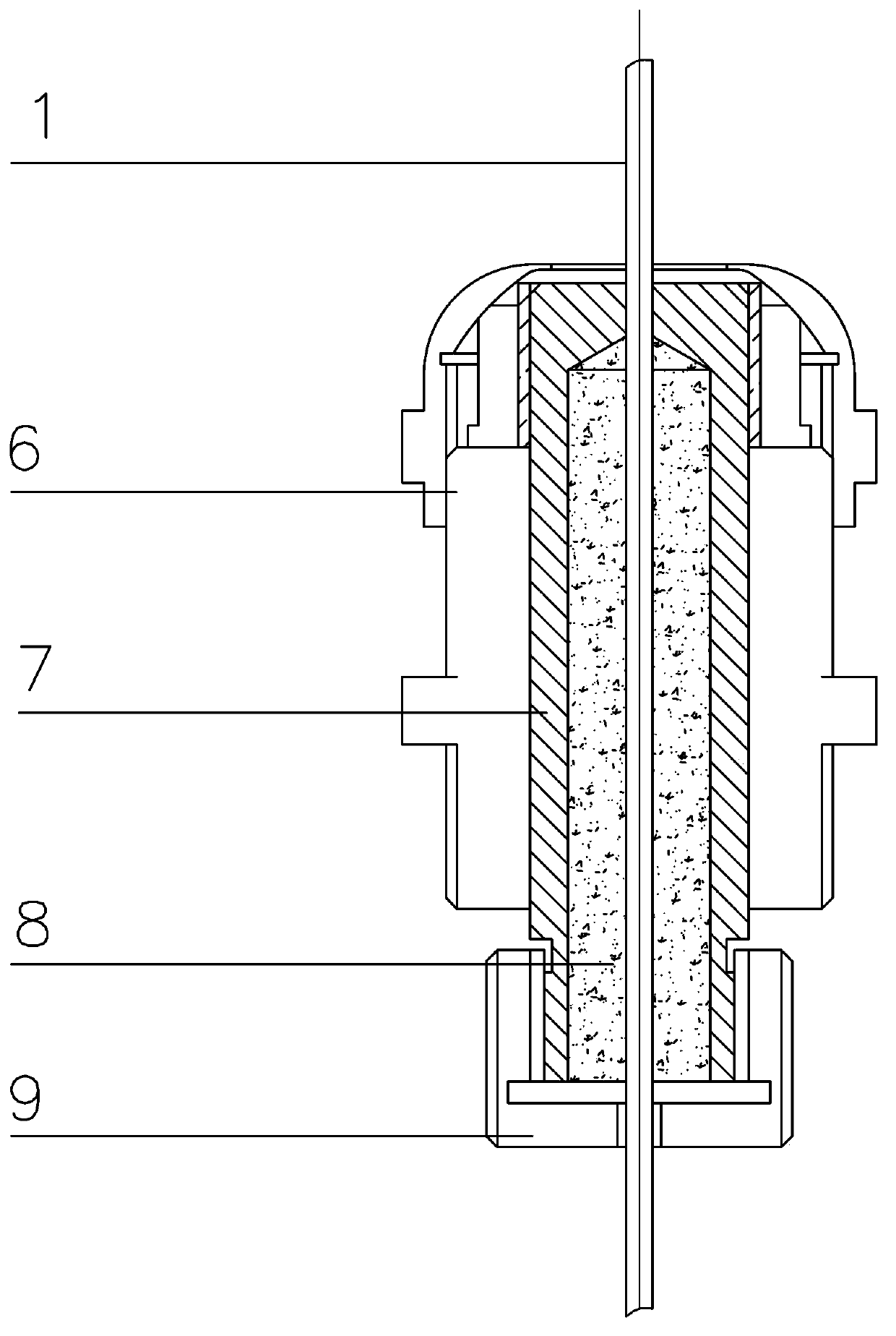

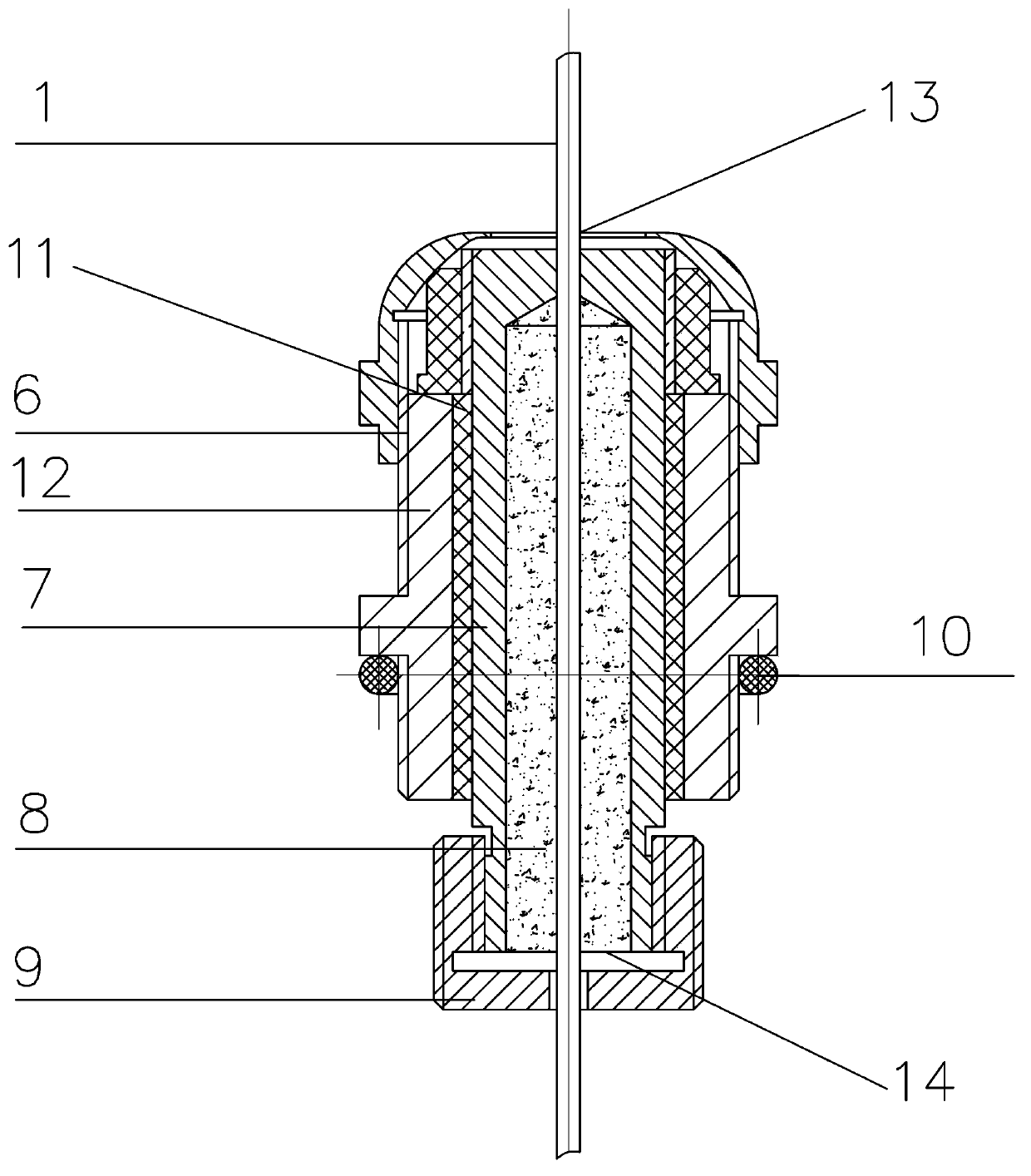

Insulator core chamber sealing device and current sensor/transformer

The invention relates to an insulator core chamber sealing device and a current sensor / transformer with the same. The insulator core chamber sealing device is used for sealing an insulator core chamber inserted with an optical fiber, and the insulator core chamber is filled with fluid or semi-fluid insulating liquid. The device comprises a waterproof connector, a sleeve, a sleeve cap and filler, the waterproof connector is in butt joint with a flange at the end of an insulator, the sleeve is inserted into the waterproof connector and clamped with the waterproof connector, holes allowing the optical fiber to penetrate are formed in end faces of both sides of the sleeve, the filler is arranged in the sleeve, fixes the optical fiber in the sleeve and functions in sealing, the sleeve cap is mounted at the tail end of the sleeve, and a hole allowing the optical fiber to penetrate is formed in the end face of the sleeve cap. The device can achieve sealability of the fluid / semi-fluid insulating liquid in the insulator core chamber for penetration of the optical fiber to further guarantee normal operation of a power grid, and has the advantages of simple structure, low processing cost, easiness in operation, high efficiency, safety and the like.

Owner:安徽新高电气有限公司

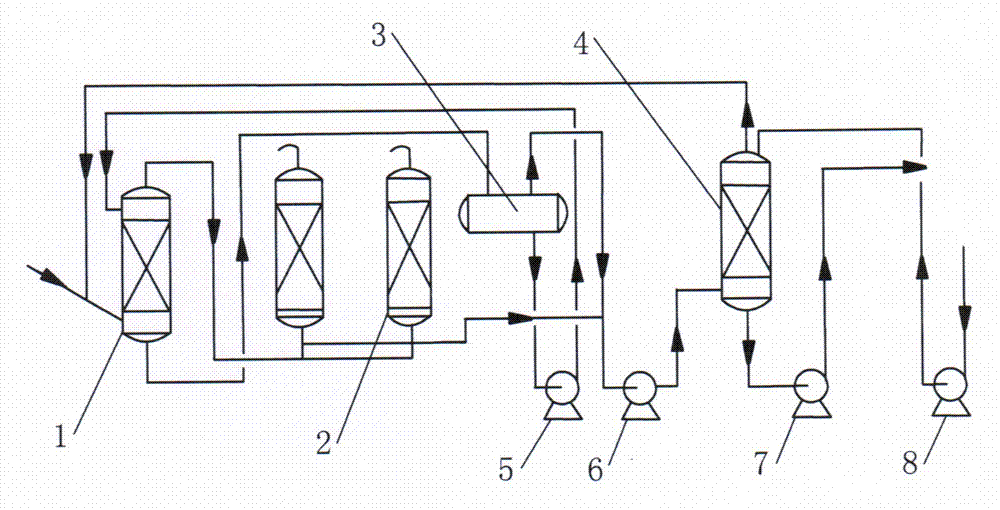

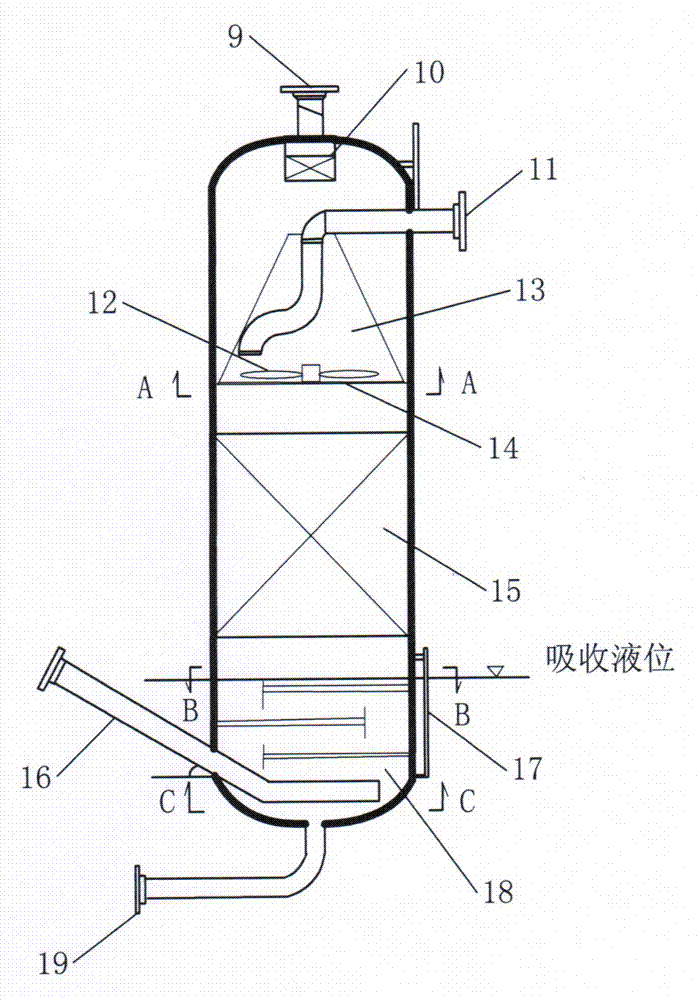

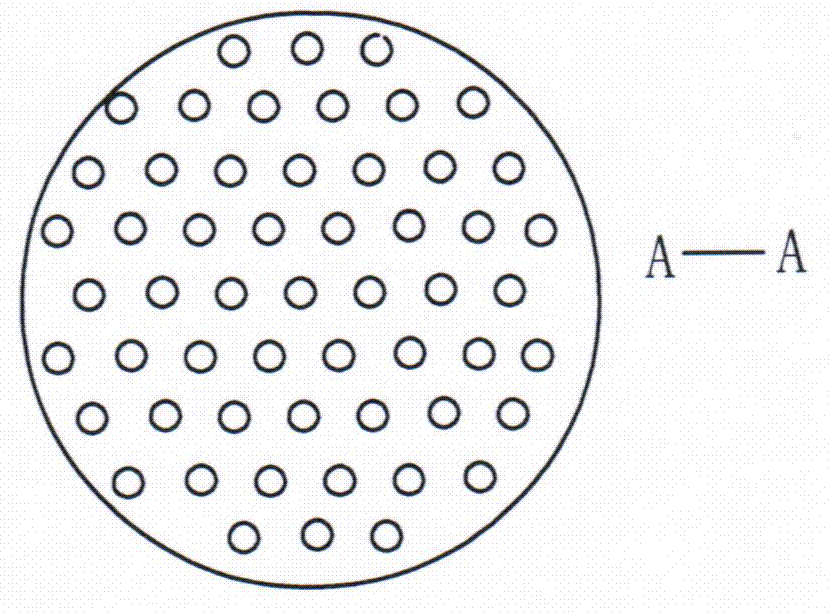

Oil-gas adsorption and absorption technical method

ActiveCN103933833AEvenly distributedEliminate the effects ofDispersed particle separationLiquid hydrocarbon mixture recoveryPhysical chemistryAnalytical chemistry

The invention provides an oil-gas adsorption and absorption technical method. Oil gas is adsorbed and absorbed through evaporated oil gas absorption, deep adsorption and desorption of tail gas, rich absorbent desorption and concentration and high-concentration oil gas recycling. Compared with the prior art, the oil-gas adsorption and absorption technical method has the advantages that oil gas can be adsorbed and absorbed as well as desorbed and recycled at the same time; the adaptive capacity is high; the equipment utilization rate is high; the oil-gas adsorption and absorption technical method is convenient and quick; by the adoption of an automatic rotary spraying device, liquid flow at an inlet is dispersed, so that an absorbent is uniformly distributed, channeling is avoided, and poor distribution of the absorbent is eliminated; a gas inlet is immersed below the liquid level of the absorbent, so that part of the oil gas can be absorbed through a liquid stored at the bottom before the oil gas enters a filler and is absorbed, and one more absorption process increases; a baffle can lengthen a path where the gas flows, the space of an absorption tower is fully used, the performance of the absorption tower is developed, the absorption efficiency of equipment and the absorbent is improved, and the oil-gas adsorption and absorption technical method is suitable for application.

Owner:HULUDAO DESIGN INST PETROCHINA NORTHEAST REFINING & CHEM ENG

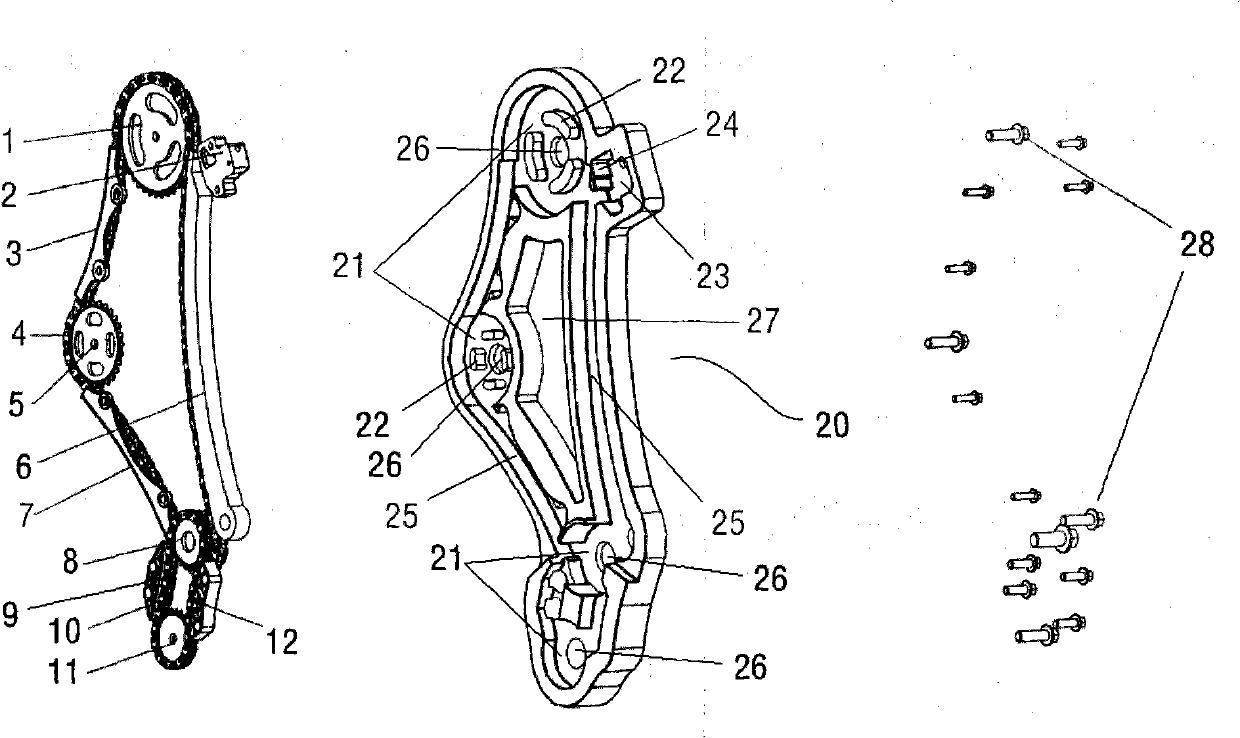

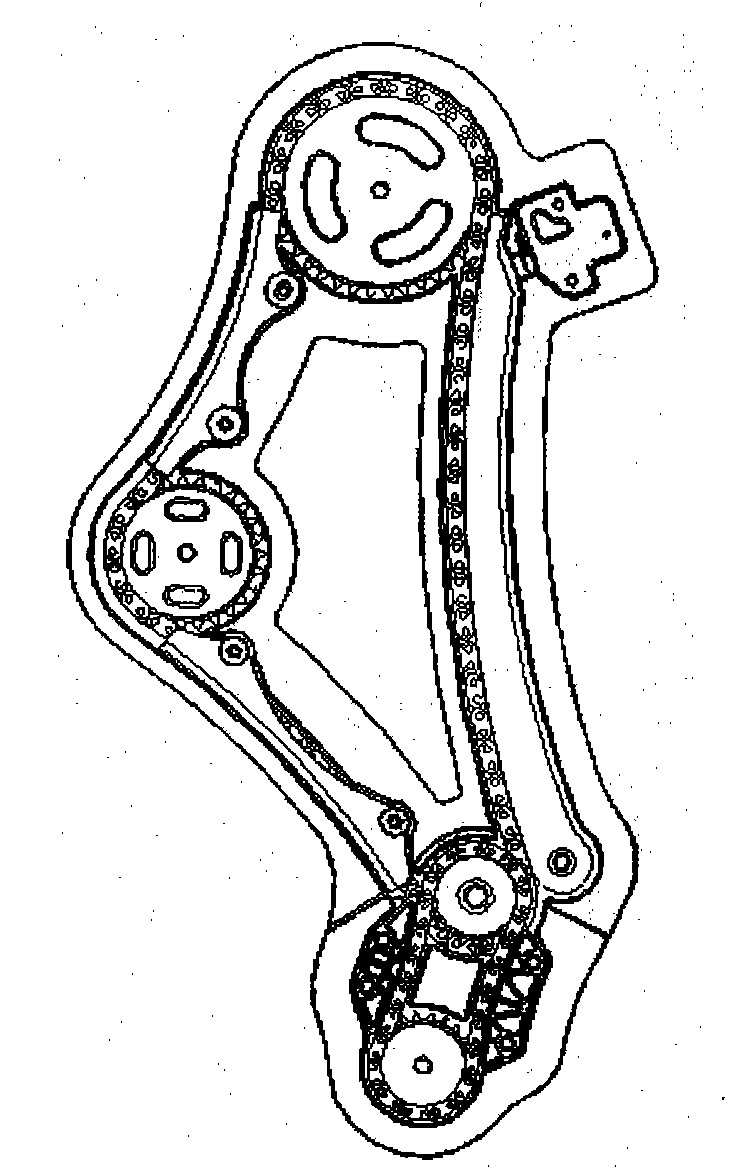

Assembly tooling and assembly method of timing chain system of engine

ActiveCN101947728AEasy to fixNot fall offWork holdersMetal working apparatusProduction lineEngineering

The invention provides an assembly tooling and an assembly method of a timing chain system of an engine, thereby improving the assembly efficiency and the quality and facilitating the inventory management of parts. The shape of the assembly tooling tallies with the shape of the well assembled timing chain system, the tooling is provided with position-limiting concave parts by corresponding all parts of the timing chain system, the tooling is provided with through holes with the hole diameter which is larger than the diameter of mounting bolts in the positions which correspond to mounting holes of all the parts, and the tooling is provided with the through holes with the hole diameter which is slightly larger than shaft holes of a chain wheel in the positions which correspond to all the shaft holes of the chain wheel. A subassembly is formed by using a special tooling to fix all the parts of the timing chain system according to the assembly positions of the whole machine, thereby facilitating the management of the parts; when the assembly is carried out on a production line, all the parts of the timing system can be aligned and assembled in place once by only aligning the relative positions of the tooling and the engine, thereby greatly reducing the labor quantity and the labor intensity of workers, and improving the assembly efficiency and the assembly quality.

Owner:CHERY AUTOMOBILE CO LTD

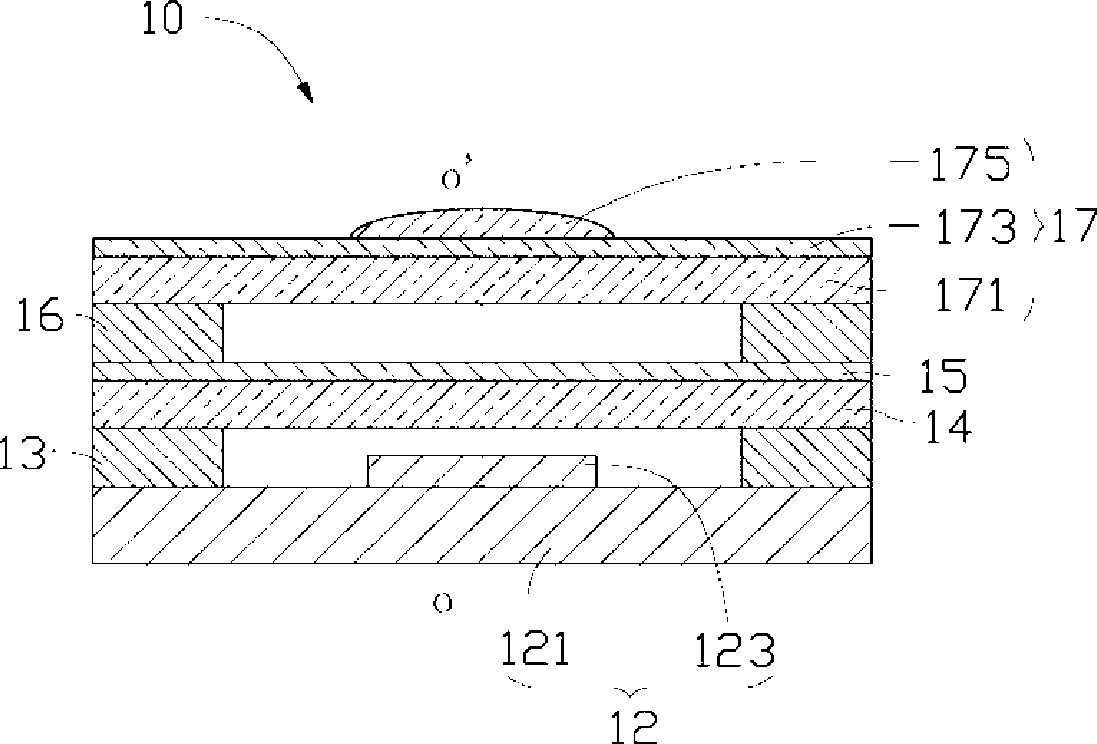

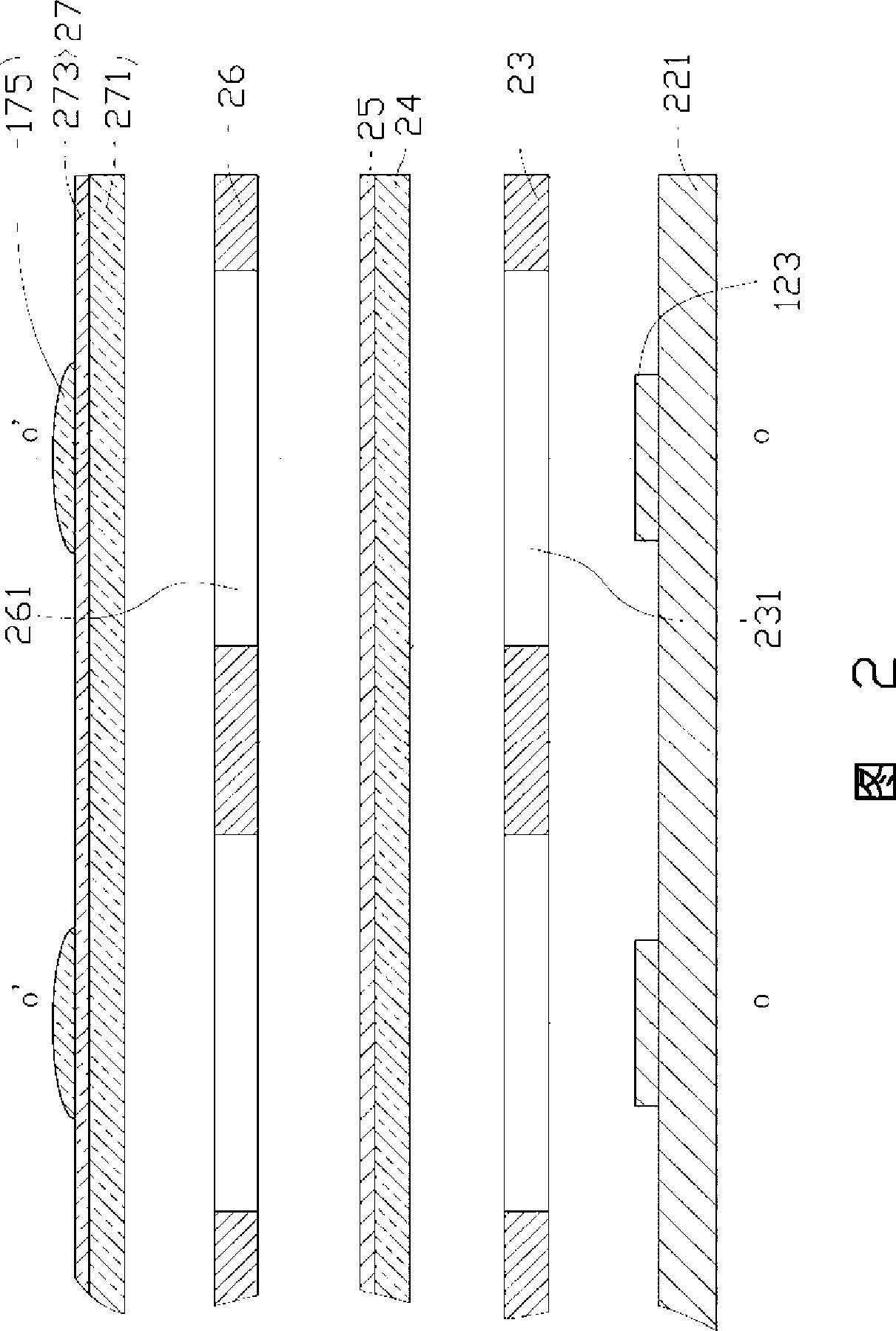

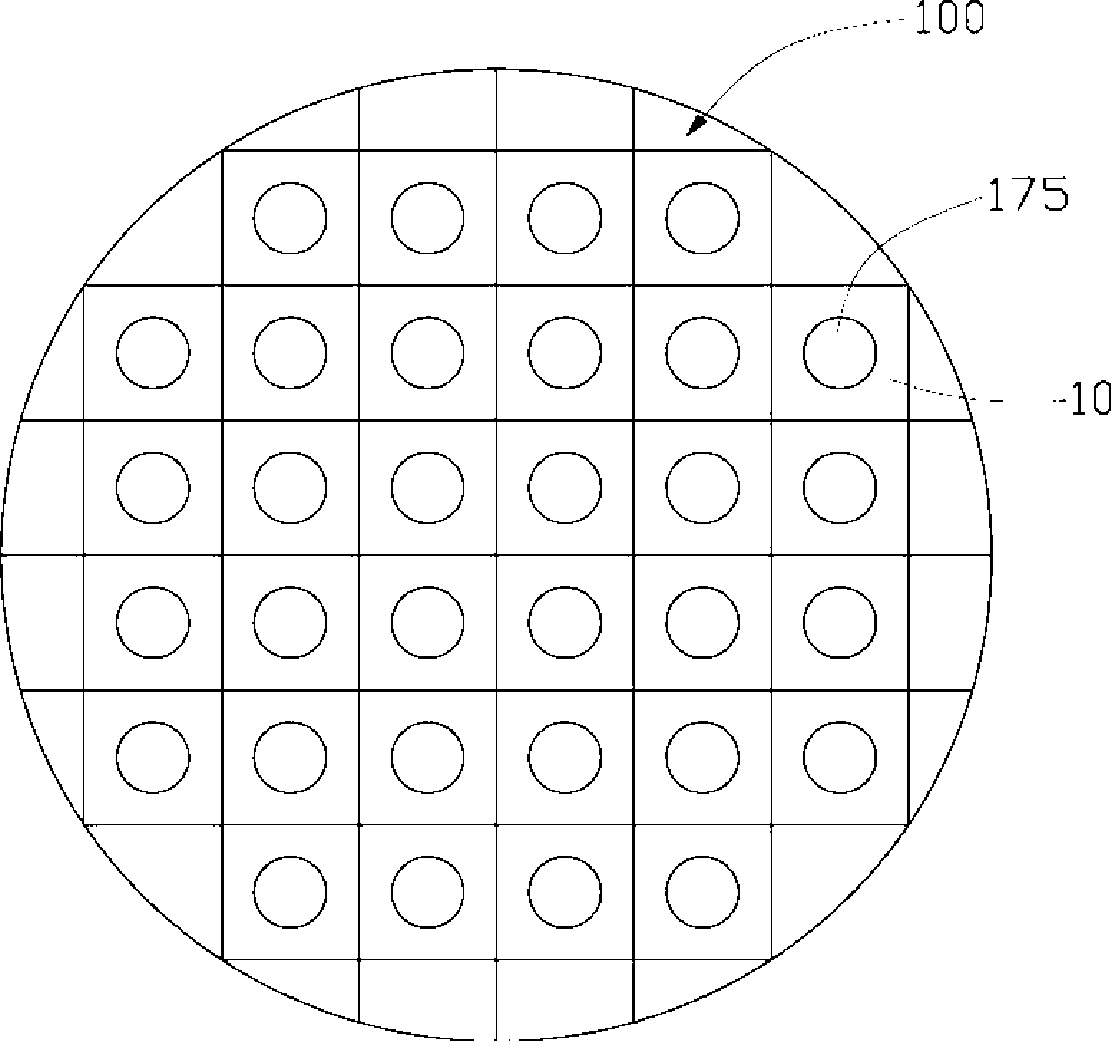

Mini camera module and method for producing the same

InactiveCN101419323AImprove adhesionNot fall offTelevision system detailsSolid-state devicesOptical axisEngineering

The invention relates to a miniature camera module and a manufacturing method thereof. The miniature camera module comprises an image sensing unit and a lens unit, wherein the image sensing unit comprises a photosensitive region; the lens unit is connected to the image sensing unit close to the photosensitive region side; the lens unit comprises a glass substrate, a transparent nucleating layer positioned on the glass substrate and a lens positioned on the transparent nucleating layer; the lens is provided with a primary optical axis; and the photosensitive region is arranged on the primary optical axis of the lens and arranged at intervals with the lens unit. The miniature camera module controls the surface tension in the forming process of the lens and increases adhesive force between the lens and the glass substrate through controlling the lens unit by the arranged transparent nucleating layer. On the one hand, over shrinkage of the lens in the forming process of the lens caused by overlarge surface tension can be inhibited; one the other hand, the lens and the glass substrate can be closely combined so as not to fall off.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Preparation method of protective coating material for zirconium alloy cladding pipe

ActiveCN106867284AGood antioxidantGood resistance to high temperature water vaporFireproof paintsMolten spray coatingZirconium alloyThermal spraying

The invention discloses a preparation method of a protective coating material for a zirconium alloy cladding pipe. Specifically, the preparation method comprises the following steps: mixing a main material for a protective coating, water and polyvinyl alcohol to obtain a mixed material; carrying out two types of post-treatment on the mixed material to obtain an agglomerated powdery protective coating raw material for the zirconium alloy cladding pipe or a suspension-shaped protective coating raw material for the zirconium alloy cladding pipe; taking the zirconium alloy cladding pipe and carrying out sand spraying treatment on an outer wall of the zirconium alloy cladding pipe; spraying the agglomerated powdery protective coating raw material for the zirconium alloy cladding pipe or the suspension-shaped protective coating raw material for the zirconium alloy cladding pipe on the outer wall of the zirconium alloy cladding pipe subjected to blast sanding treatment by adopting a thermal spraying technology, so as to form the protective coating material for the zirconium alloy cladding pipe on the outer wall of the zirconium alloy cladding pipe. According to the preparation method of the protective coating material for the zirconium alloy cladding pipe, provided by the invention, a very good protective coating is formed on the outer wall of the zirconium alloy cladding pipe, so that the anti-oxidization performance of the zirconium alloy cladding pipe is improved.

Owner:陕西华秦科技实业股份有限公司

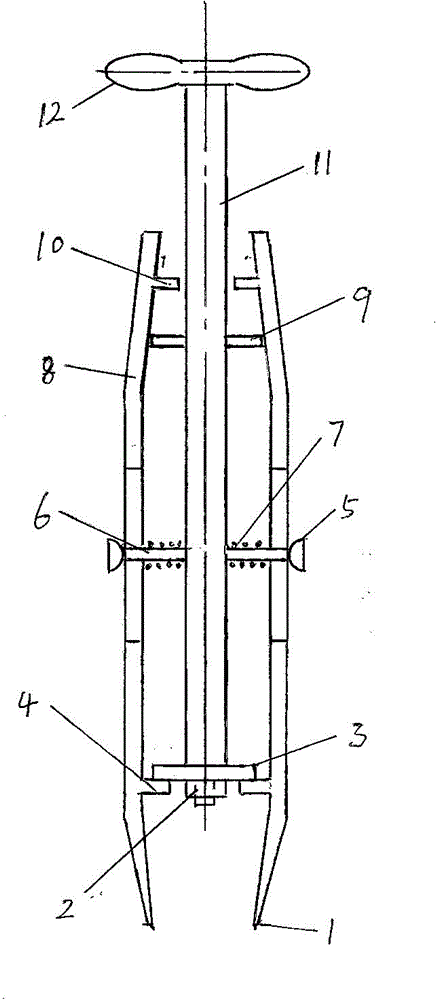

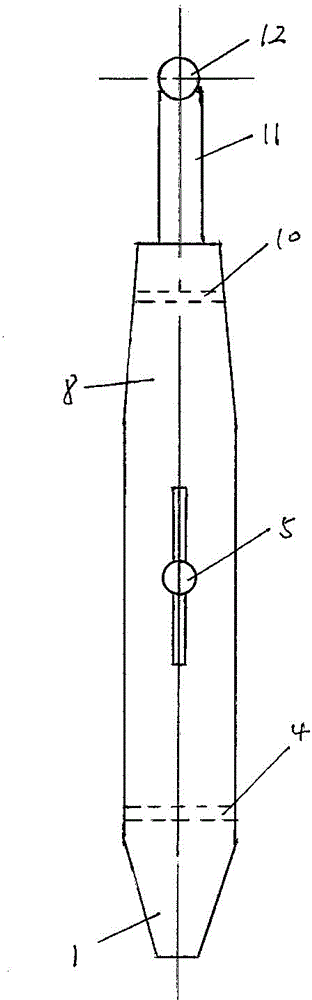

Weed root removing machine

InactiveCN105409360ASwipe Up and Down GuaranteedGuaranteed to slide up and downGatherer machinesAgricultural engineeringWeed

The invention provides a weed root removing machine. The weed root removing machine consists of shovel edges, compression nuts, a pressure plate, pressing blocks, a semi-circular head, a stabilizing rod, a spring, a shovel body, a supporting plate, an abutting block, a spindle and a handle, wherein the two shovel edges are correspondingly distributed on two sides of the spindle and are inclined inwards; the tail of the shovel body is in the shape of an inclined plane and the diameter of the tail is relatively small; each pressing block is arranged at the tail of the corresponding shovel edge; the abutting block is arranged at the tail of the shovel body; and the pressure plate is arranged at the front end of the spindle. When using the weed root removing machine, a user holds the handle with hands, aligns the two shovel edges to weed roots, pushes the handle so that the two shovel edges are pressed in the weed root part in the soil; and after the handle is lifted up, the two shovel edges clamp the weed roots and pull the weed roots out, so that the effect of removing stubborn weed roots is achieved.

Owner:天太·郭元焜

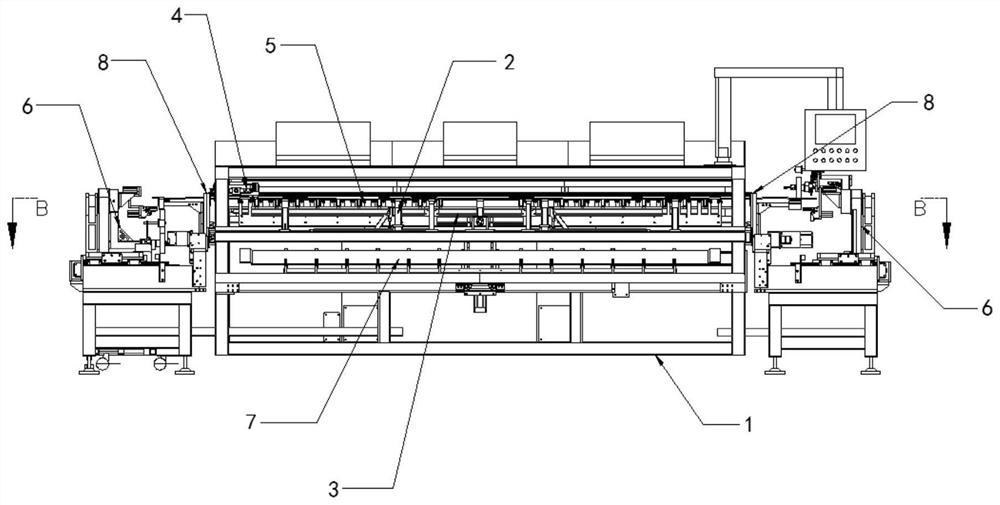

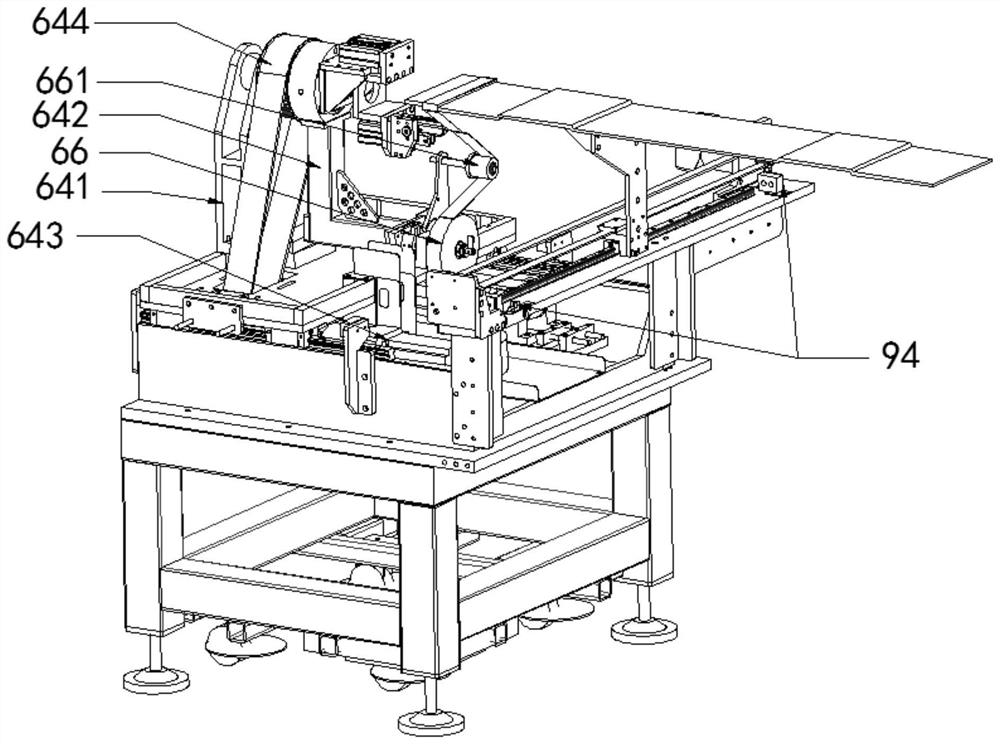

Automatic glue winding machine for plates

ActiveCN113410007AReduce widthMeet winding needsFinal product manufactureInsulating conductors/cablesWinding machineBus

The invention relates to an automatic glue winding machine for plates, which comprises a rack, a workbench, a material pushing mechanism, a centering clamping mechanism, a material supporting lifting mechanism, two glue winding mechanisms and a discharging mechanism, the workbench, the material pushing mechanism and the material supporting lifting mechanism are sequentially arranged in the middle of the rack from front to back, the centering clamping mechanism is arranged above the material supporting lifting mechanism. The discharging mechanism is arranged below the material supporting and lifting mechanism, the two adhesive tape winding mechanisms are arranged on the left side and the right side of the rack correspondingly, the workbench is horizontally arranged and connected with one end of the material pushing mechanism, and the workbench is used for containing a blank. The glue winding machine fills the blank of a glue winding machine in the bus industry, solves many problems existing in manual glue winding of the bus, can achieve glue winding work of the ends of the buses of different specifications, integrates bus transportation, end glue winding and automatic discharging, achieves continuous operation, is free and adjustable in glue winding angle and convenient to operate, and improves the production efficiency. The mechanization and automation degree of bus glue winding is improved.

Owner:WUHAN TEXTILE UNIV

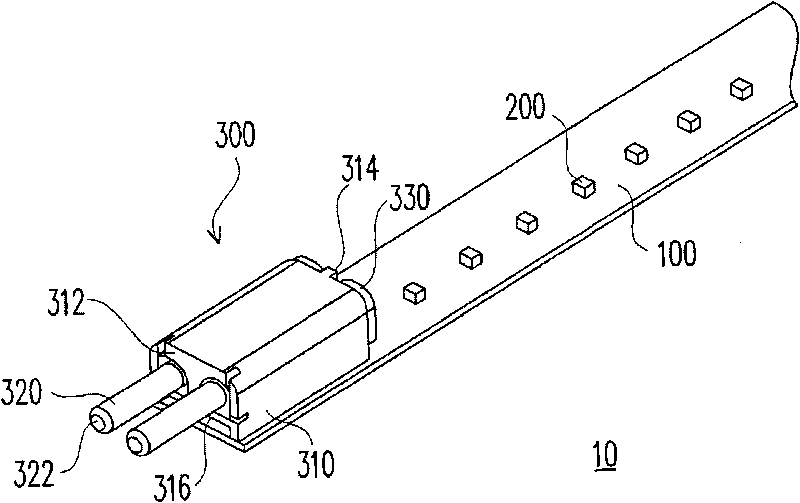

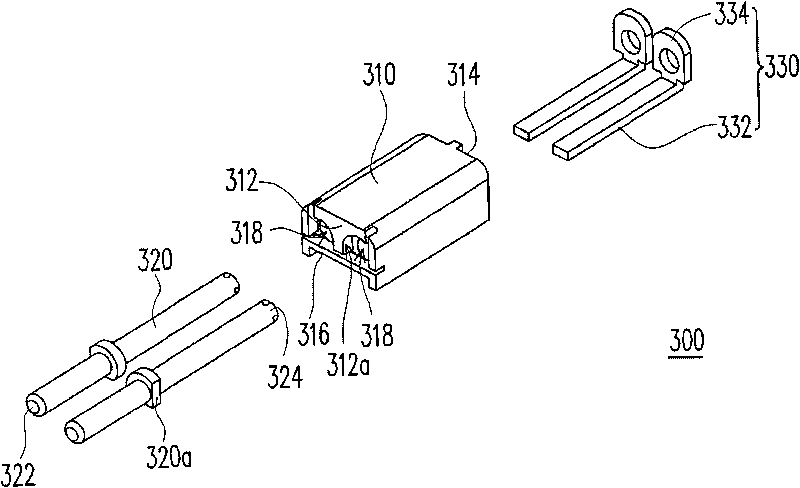

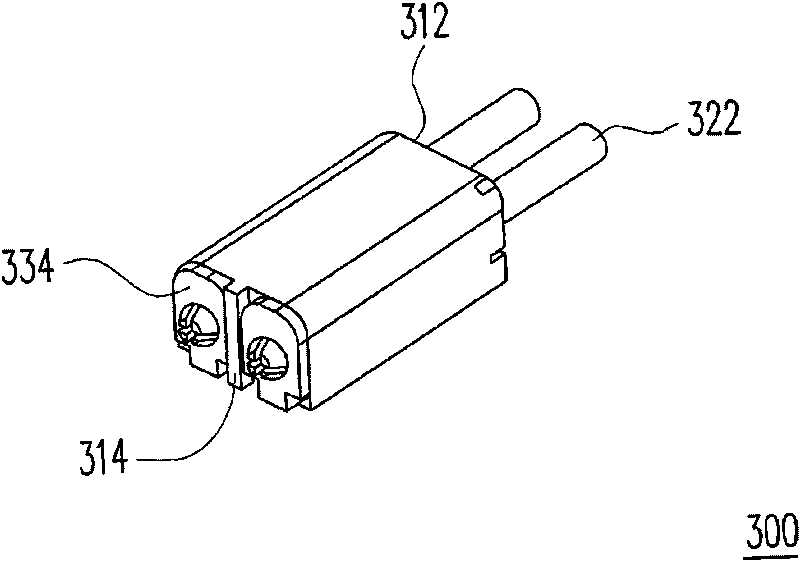

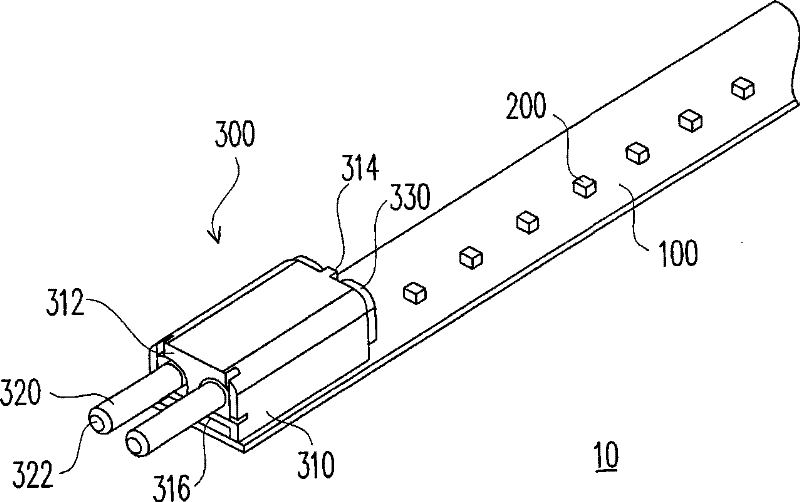

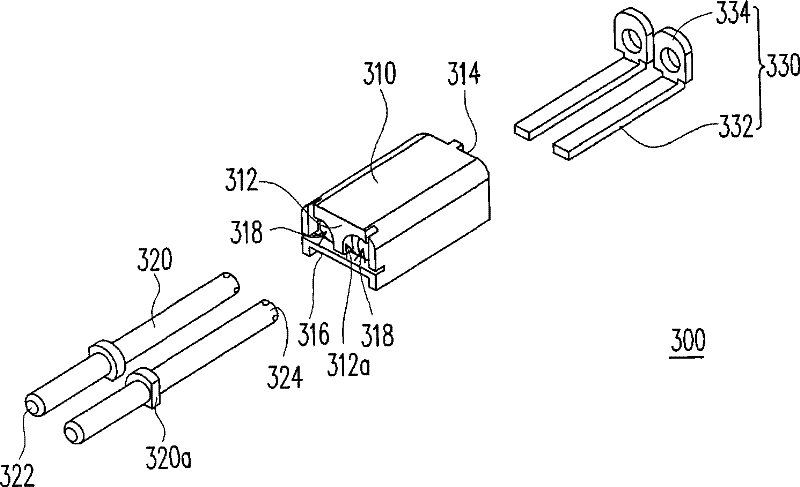

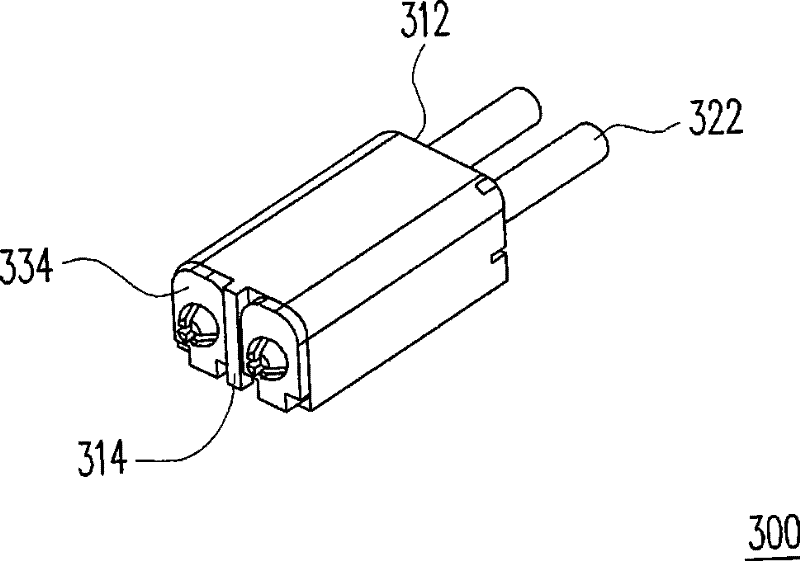

Connector and light source device

InactiveCN101740984AImprove reliabilityNot fall offCoupling device connectionsElectric discharge tubesEngineeringElectrical and Electronics engineering

The invention relates to a connector comprising an insulating seat, two electrode posts and two L-shaped electrode slices, wherein the insulating seat is provided with a first side surface, a second side surface opposite to the first side surface, a lower surface for connecting the first side surface with the second side surface and two through holes, and the two through holes penetrate through the insulating seat and extend to the second side surface from the first side surface; the two electrode posts respectively penetrate through the two through holes, each electrode post is provided with a first end and a second end which are opposite to each other, and the first end protrudes the first side surface; each L-shaped electrode slice comprises a bottom arranged on the lower surface and a connecting part connected to the bottom, and the connecting parts are arranged on the second side surface and are respectively connected to the second ends of the electrode posts.

Owner:EVERLIGHT ELECTRONICS

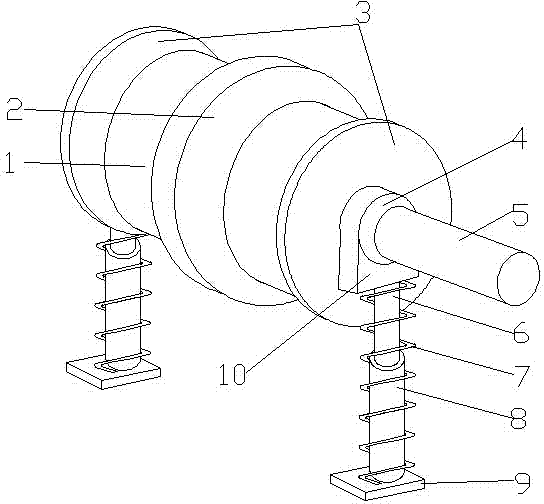

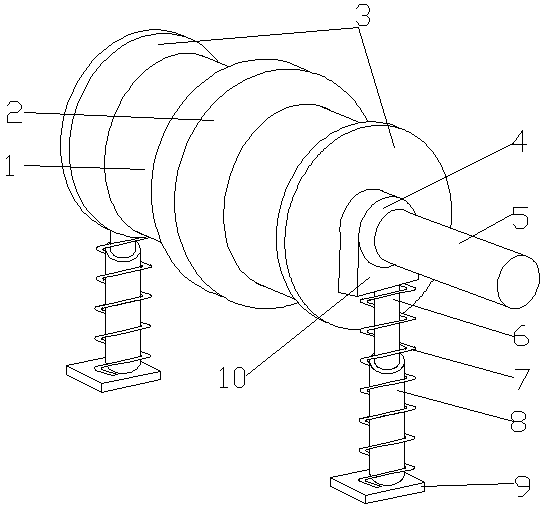

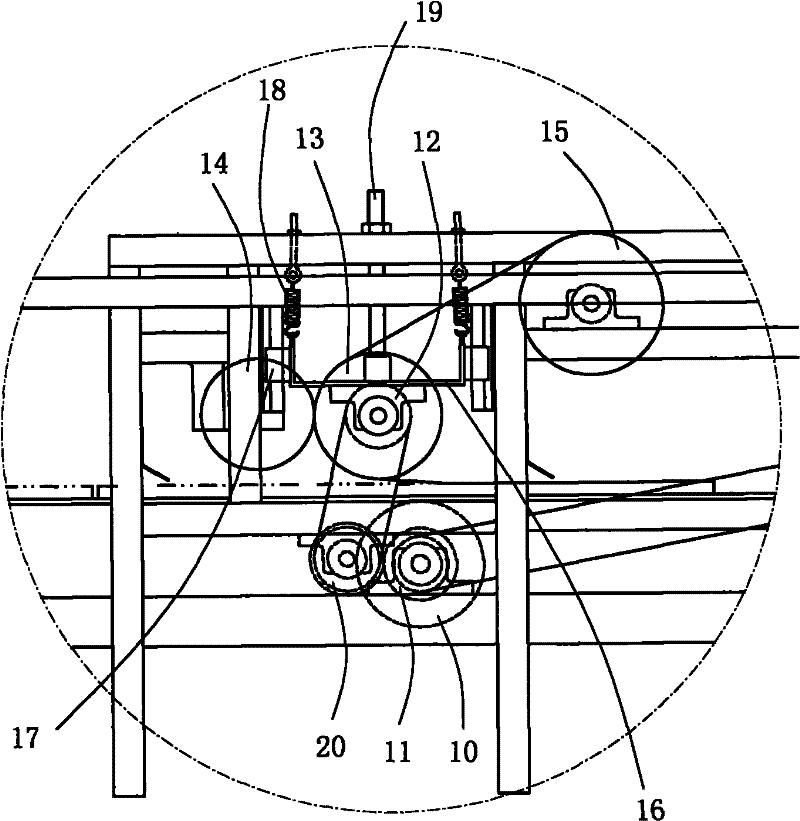

Automatically adjusted line pressing wheel device

InactiveCN104492839AHigh mechanical strengthHigh softening pointDrive motorManufacturing engineering

The invention discloses an automatically adjusted line pressing wheel device and belongs to the field of metal manufacturing equipment. The device comprises a line pressing wheel, a bearing, a universal bearing and an elastic supporting structure, wherein limiting baffles are fixed at two ends of the line pressing wheel, and a limiting separator is fixedly arranged in the middle of the line pressing wheel; one end of a rotating shaft of the line pressing wheel is fixedly connected with a universal joint shaft; the universal joint shaft is connected with a driving motor; the elastic supporting structure comprises a supporting seat, a spring, a telescopic mechanism and a fixing rack; and the telescopic mechanism comprises a loop bar and a sleeve. According to the device disclosed by the invention, a phenomenon that a soft state alloy wire rod is scratched, collided or pressed to generate indentation can be avoided, the line pressing wheel device is applied to line pressing of soft-state alloy materials such as H65 materials, the materials can be recycled, the service life is long, the use rate of the line pressing wheel can be improved, and balanced tensioning degree of the wire rods in the high-speed transfer process is guaranteed, so that the phenomenon that a gold thread is severely pulled even broken is avoided.

Owner:WUHU MINTAI COPPER IND

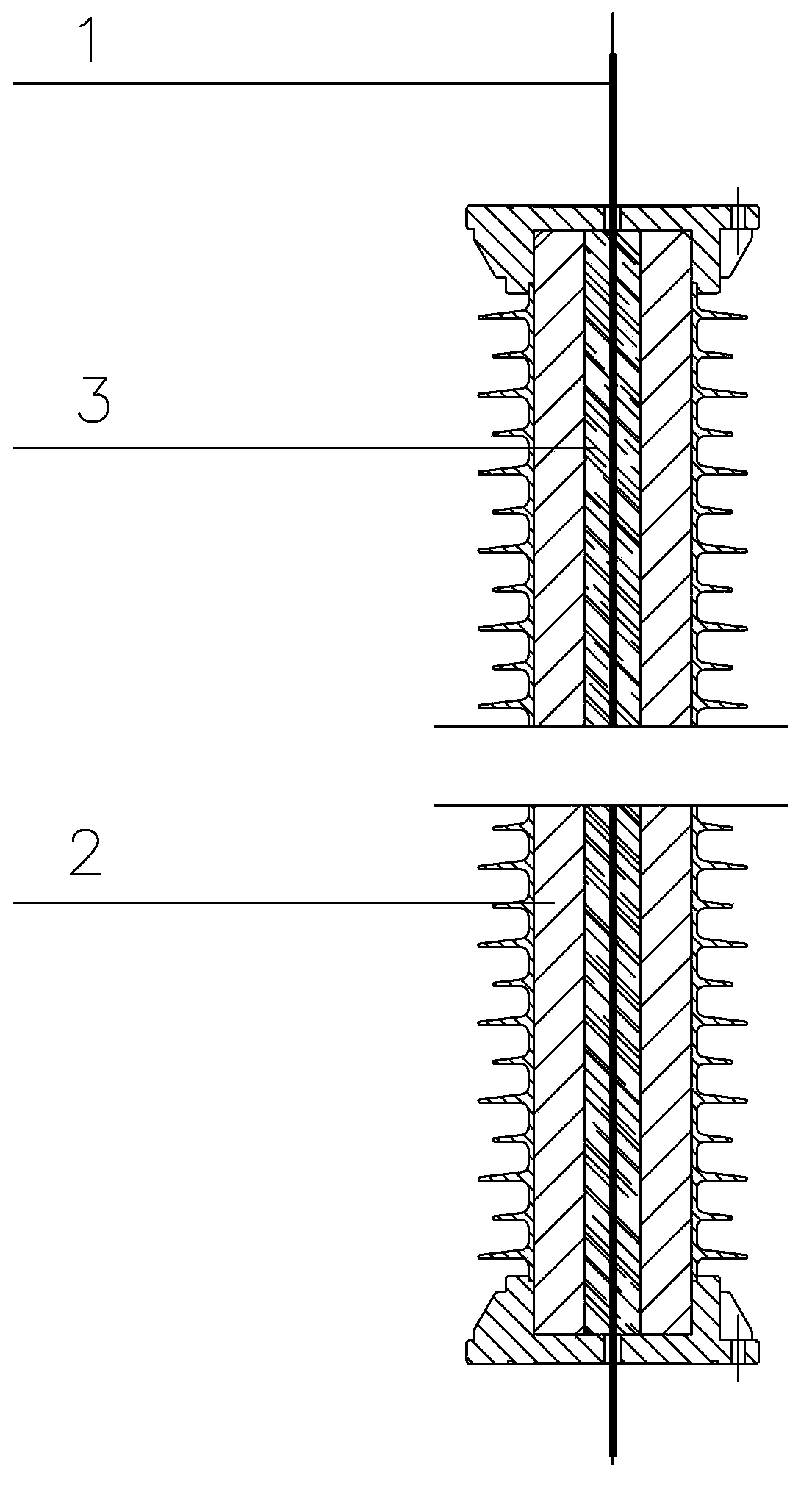

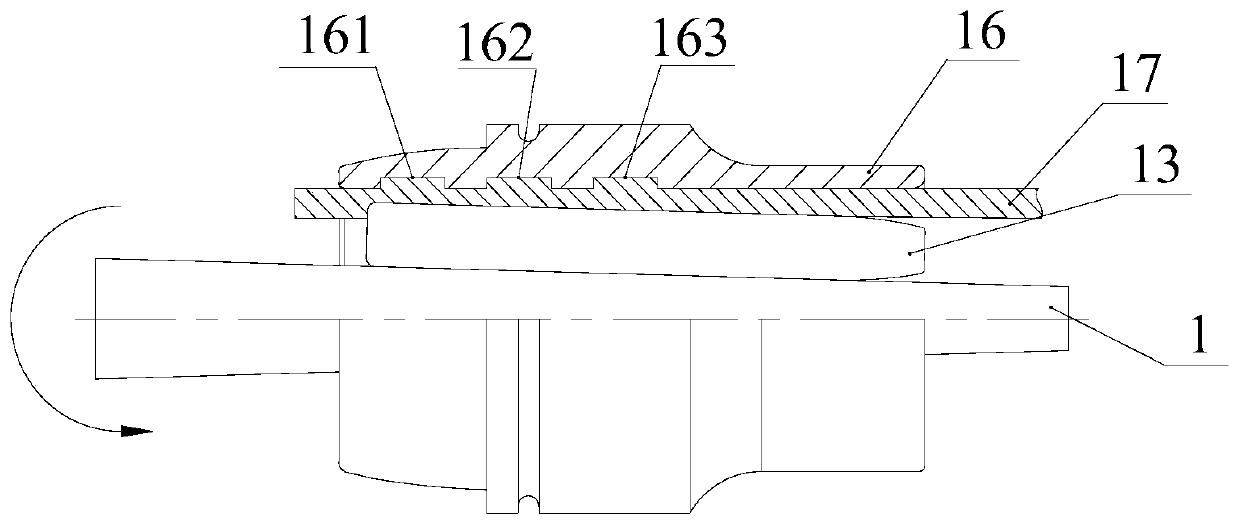

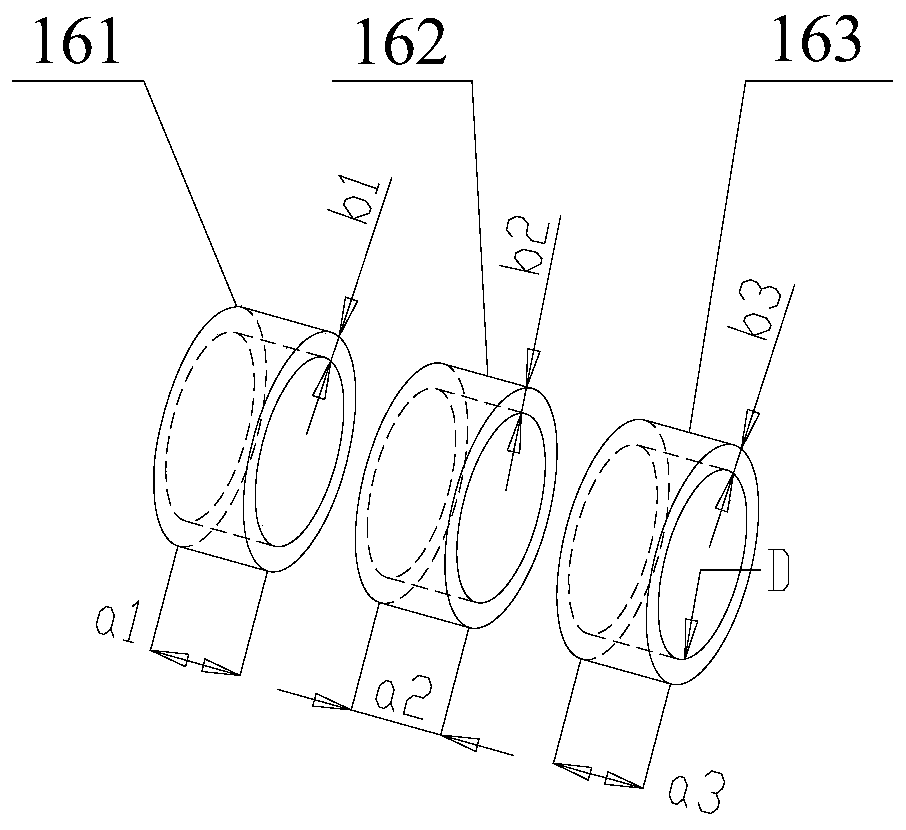

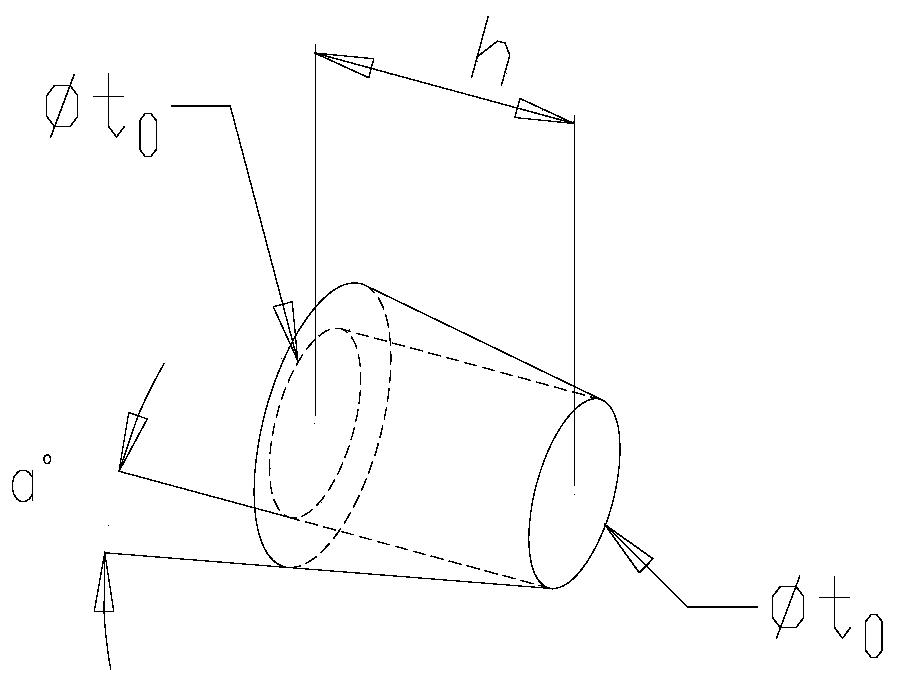

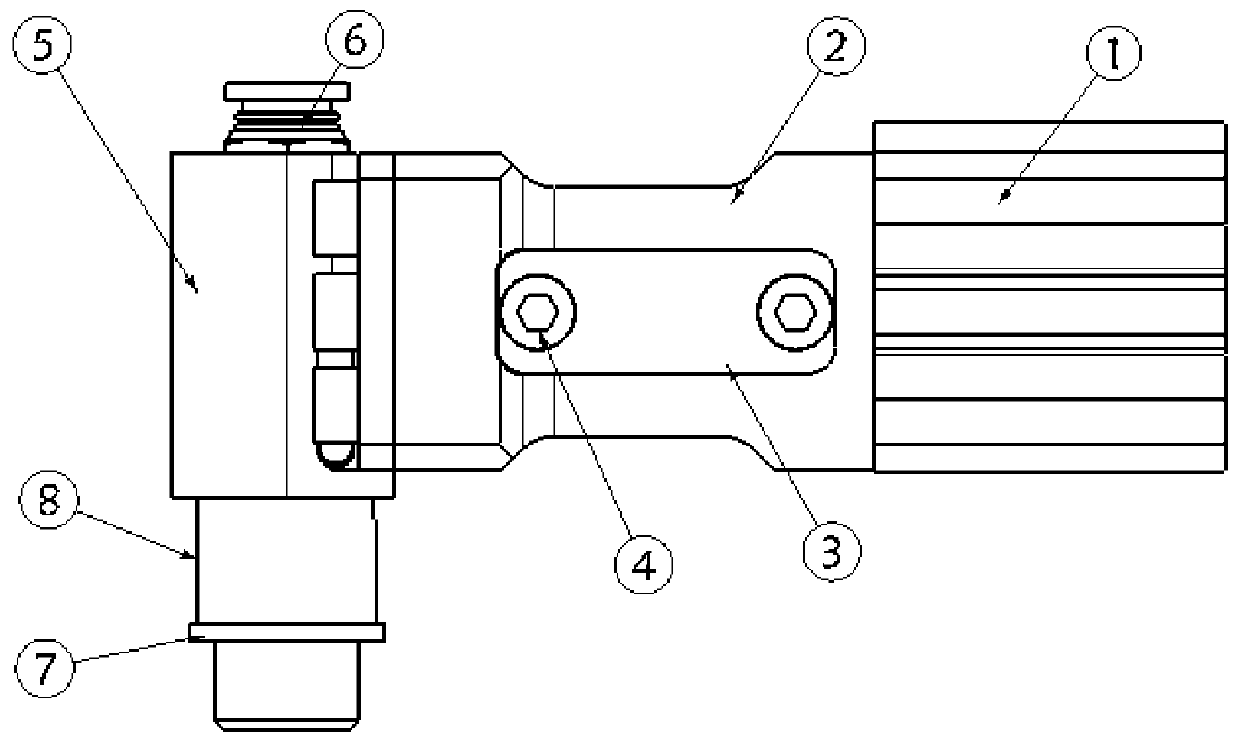

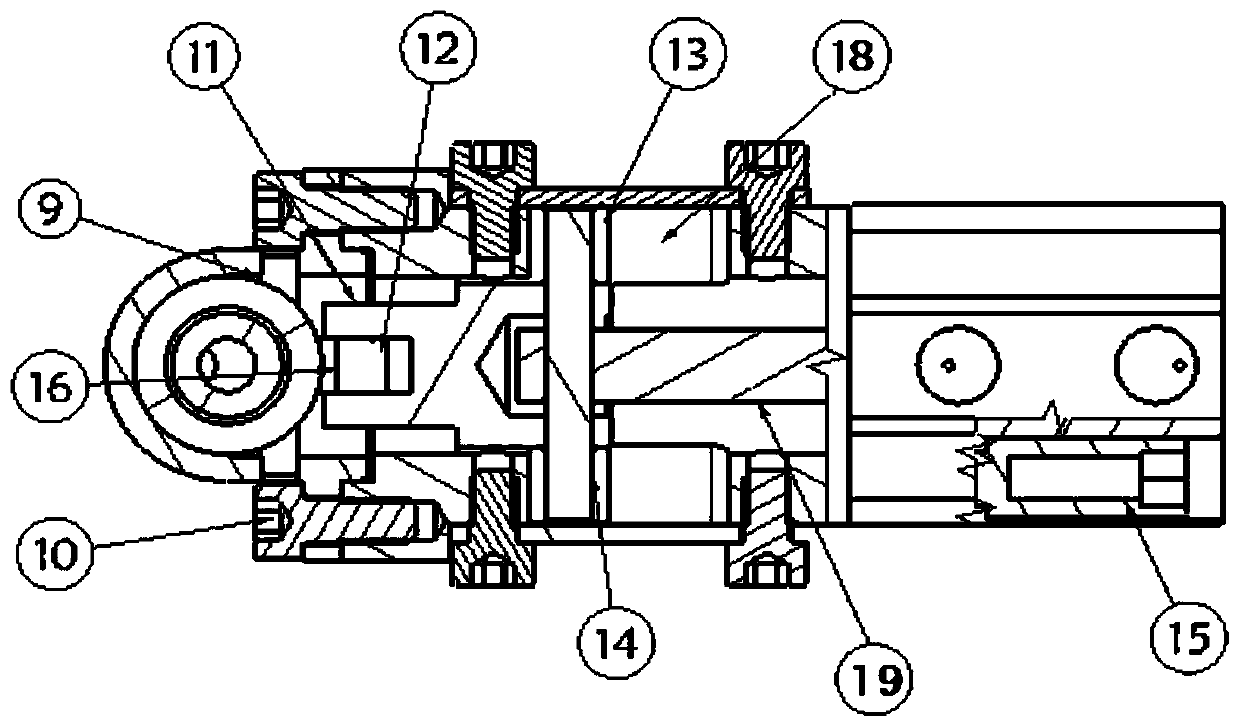

Rolling connection forming tool of pipe joint based on high filling rate and rolling connection process

ActiveCN111346980AExtended service lifeImprove rolling qualityMetal-working feeding devicesPositioning devicesHardnessPipe

The invention provides a rolling connection forming tool of a pipe joint based on a high filling rate and a rolling connection process. The tool comprises an inner diameter expander and a clamping die. The tool is characterized in that a mandrel arranged in a mandrel cover in a sleeved manner and used for implementing rolling rotation in the inner diameter expander is of a spilt structure which isdivided into a working end and a non-working end; the working end is a part inserted into a metal guide pipe for implementing rolling rotation of the mandrel matched with the mandrel cover, is of a cone structure, and the outer diameter of the working end tends to decrease gradually in a direction pointed to insertion; and the taper of the working end of the mandrel meets a certain relational expression. The rolling process is that a high hardness smooth roller pin is in contact with the inner wall of the metal guide pipe by the tool, so that local plastic deformation occurs in a surface layer of the metal guide pipe to generate surface pressure stress, and a pipe wall material is rolled into the pipe joint with a groove to achieve rolling connection. The rolling connection forming tool has the advantages of reasonable structural design, improved performance of a rolled product, high percent of pass and the like.

Owner:DALIAN CANDL TECH DEV CO LTD +1

Electric machine stand corner plate welding base

ActiveCN101462210AReduce the human factorImprove product qualityPrecision positioning equipmentWelding/cutting auxillary devicesElectric machineMechanical engineering

The invention relates to an angle plate welding seat of a motor stand. The angle plate welding seat comprises a base, an up-and-down floating mechanism, a bracket plate, a fixing plate, an indexing rotation mechanism, a clamp fixing mechanism, a clamp discharging mechanism and a welding electrode; the up-and-down floating mechanism is arranged on the base and can float up and down; the bracket plate and the fixing plate are arranged on the up-and-down floating mechanism respectively; the indexing rotation mechanism is arranged on the bracket plate; the clamp fixing mechanism is connected with the indexing rotation mechanism and is rotatably connected with the bracket plate and the fixing plate respectively; the clamp fixing mechanism can realize indexing rotation under the drive of the indexing rotation mechanism; the clamp discharging mechanism is arranged on the fixing plate and sleeved on the clamp fixing mechanism; the clamp discharging mechanism can have axial movement and outwards push a clamp out from the clamp fixing mechanism to realize discharging; and the welding electrode is connected with the clamp fixing mechanism. The angle plate welding seat is used for loading and rotating a welding clamp with the motor stand, improves welding quality and production efficiency, reduces labor intensity of an operator and has large use value.

Owner:SHANGHAI RIYONG JEA GATE ELECTRIC

A self-adjustable crimping wheel device

Owner:WUHU MINTAI COPPER IND

Low-temperature light-weight high-strength porcelainfor daily use and preparation method thereof

ActiveCN112851303AHigh strengthGranules are stableCeramic materials productionClaywaresGlazePhysical chemistry

The invention discloses low-temperature light-weight high-strength porcelain for daily use, which comprises the following raw materials in parts by weight: 2-5 parts of pottery clay, 5-8 parts of bentonite, 5-8 parts of sand and 4-9 parts of clay, and further comprises the following glaze raw materials in parts by weight: 10-15 parts of clam shell powder, 2-5 parts of bentonite, 10-12 parts of cordierite and 12-22 parts of albite. The preparation method of the glaze comprises the steps of putting the clam shell powder, the cordierite and the albite in parts by weight into liquid nitrogen, freezing for 20-24 hours, then taking out the clam shell powder, the cordierite and the albite, immediately adding the clam shell powder, the cordierite and the albite into a ball mill, carrying out dry grinding for 2-3 hours to obtain powder, carrying out constant-temperature stirring on the powder and the bentonite in parts by weight in a high-speed mixer at the temperature of 30-35 DEG C for 15-20 minutes to obtain a mixed material, and carrying out anaerobic calcination on the mixed material at the temperature of 100-120 DEG C to obtain the glaze. The porcelain for daily use obtained by the invention is light in weight and high in strength, and can be fired at low temperature.

Owner:福建省德化县宝瑞陶瓷有限公司

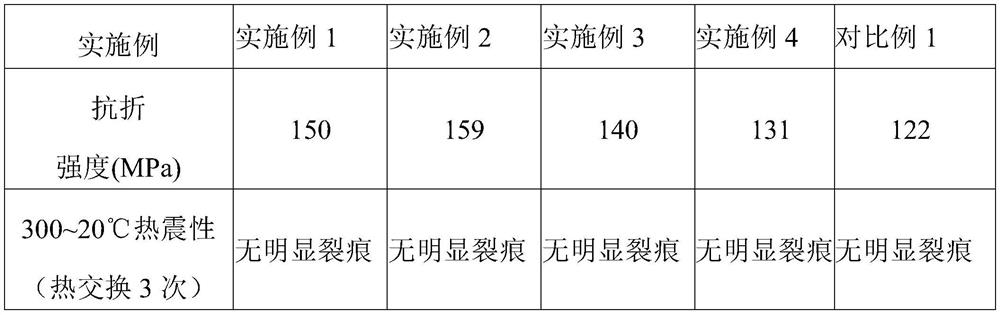

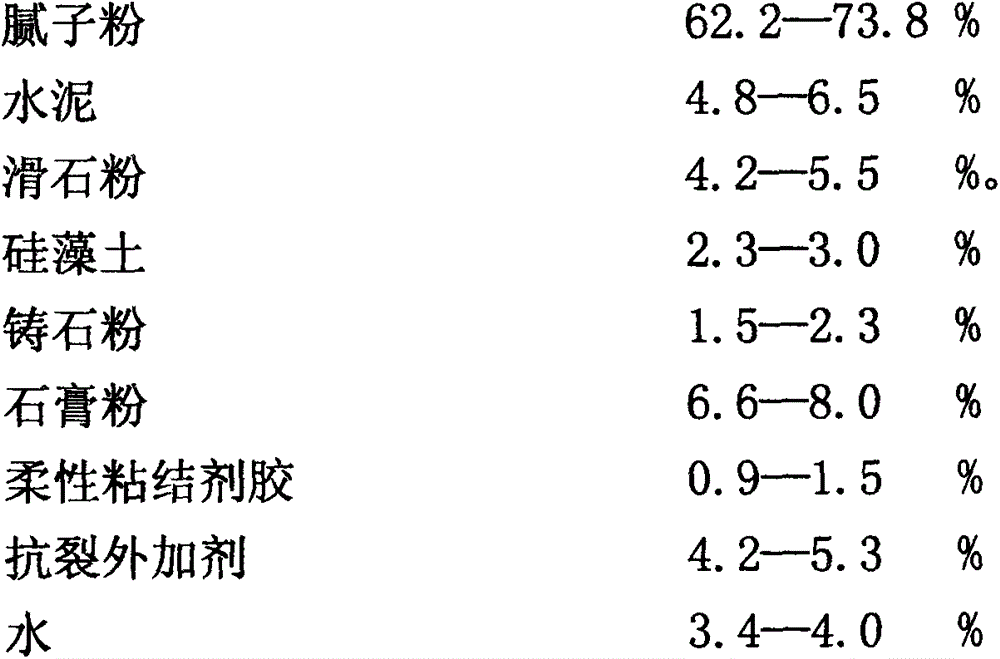

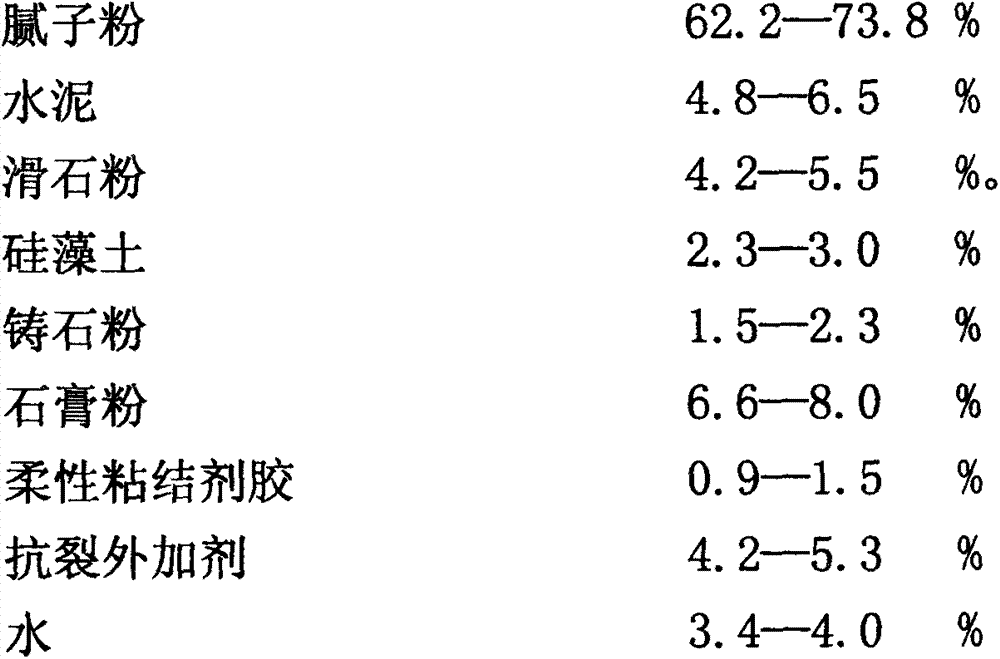

Formula of special putty base mixture for aerated block masonry, and preparation method of special putty base mixture

The invention relates to a formula of a special putty base mixture for aerated block masonry, and a preparation method of the special putty base mixture. The preparation method comprises the following steps: preparing a special barrel with the volume of 50L; sequentially adding 62.2-73.8wt% of putty powder, 4.8-6.5wt% of cement, 6.6-8.0wt% of gypsum powder, 1.5-2.3wt% of cast stone powder, 4.2-5.5wt% of talcum powder, 2.3-3.0wt% of diatomite, 3.4-4.0wt% of water, 0.9-1.5wt% of a flexible adhesive and 4.2-5.3wt% of a crack resistance additive to the special barrel; and stirring by using a portable electric stirring machine for 3-5min to form a uniform paste, allowing the paste to stand for 5-10min, and stirring to obtain the putty base mixture which can be instantly used. The special putty base mixture can be directly smeared on the aerated block masonry to omit a mortar plastering process and avoid material sprinkling, so the environment is healthy, and cracking and bubbling are avoided; and the special putty base mixture has the advantages of high strength, large adhesion, and no shedding in wet environment.

Owner:NANTONG SIJIAN CONSTR GRP

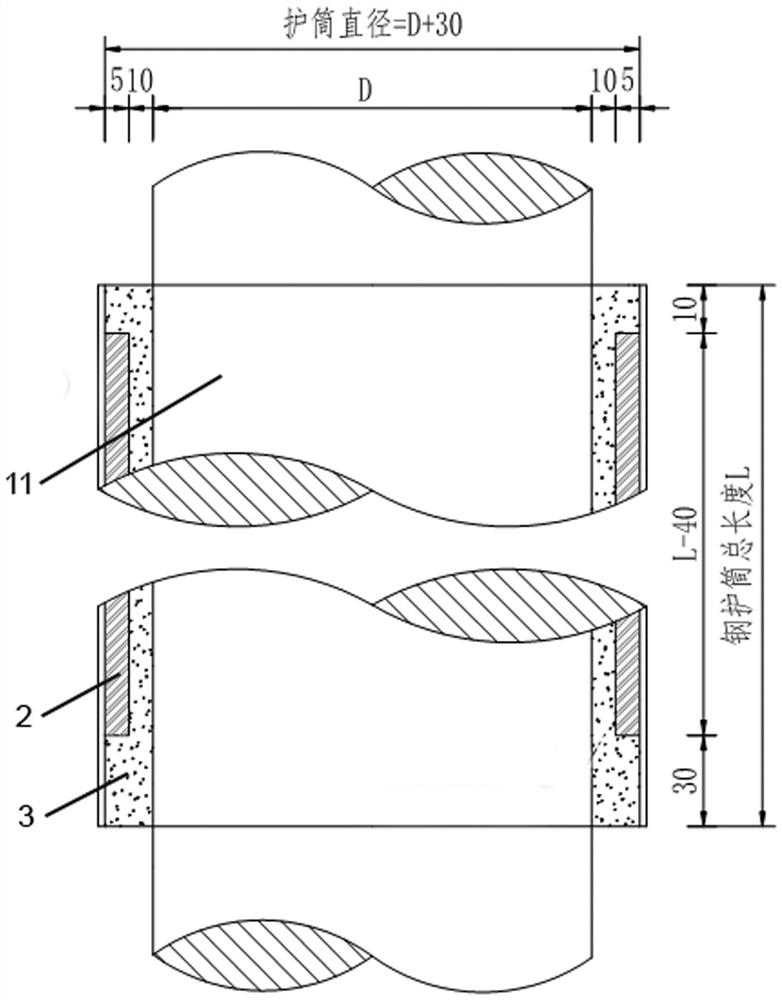

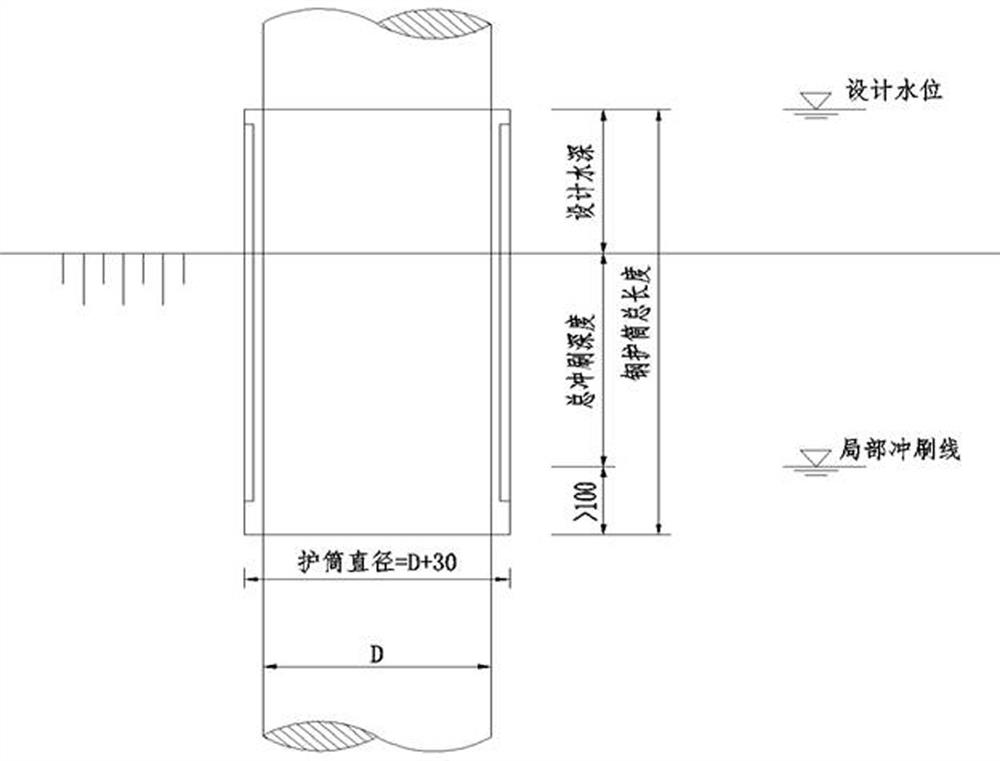

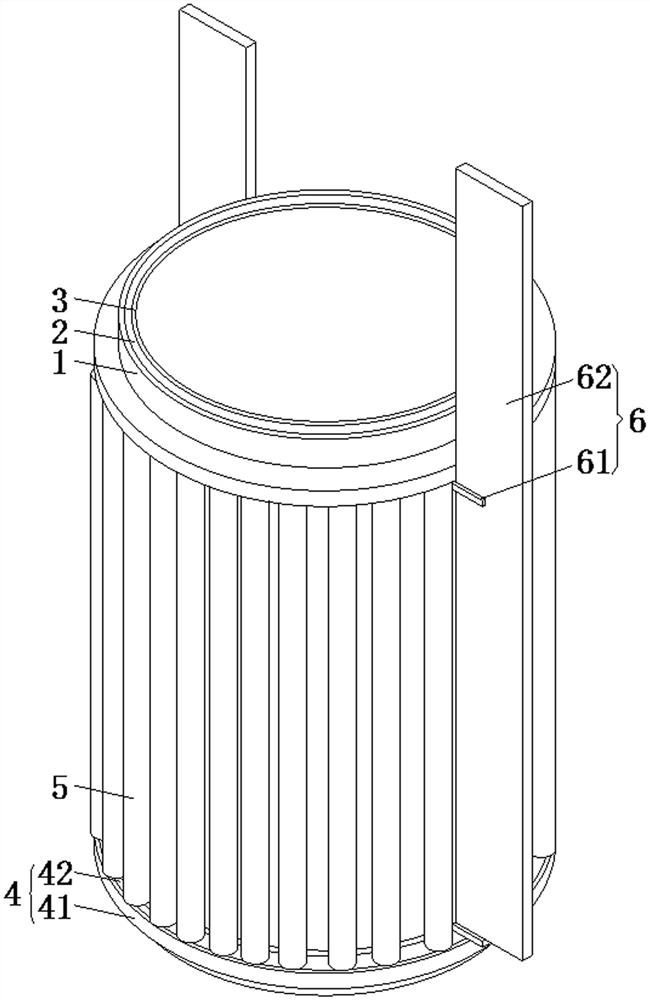

Anti-collision and anti-corrosion device for bridge pier column and construction method of anti-collision and anti-corrosion device

PendingCN114277669AAnti-collision effectEffectively fixedBridge structural detailsBridge erection/assemblySteel platesPier

The invention relates to the technical field of bridge protection, and discloses an anti-collision and anti-corrosion device for a bridge pier stud, the anti-collision and anti-corrosion device for the bridge pier stud comprises a pile casing arranged outside the pier stud, the pile casing is formed by rolling a steel plate, the outer surface of the pile casing is subjected to thermal spraying zinc treatment, and the pile casing is lined with buffer rubber; a self-compacting fine stone C40 concrete layer is poured between the buffer rubber and the pier column. The scheme of the steel casing, the rubber plate and the filling concrete can play a role in preventing collision and abrasion of the pier. Impact energy of debris flow can be damped and absorbed through the rubber plate. On the other hand, the invention provides a construction method of the anti-collision and anti-corrosion device for the bridge pier column.

Owner:GUANGDONG GUANYUE HIGHWAY & BRIDGE

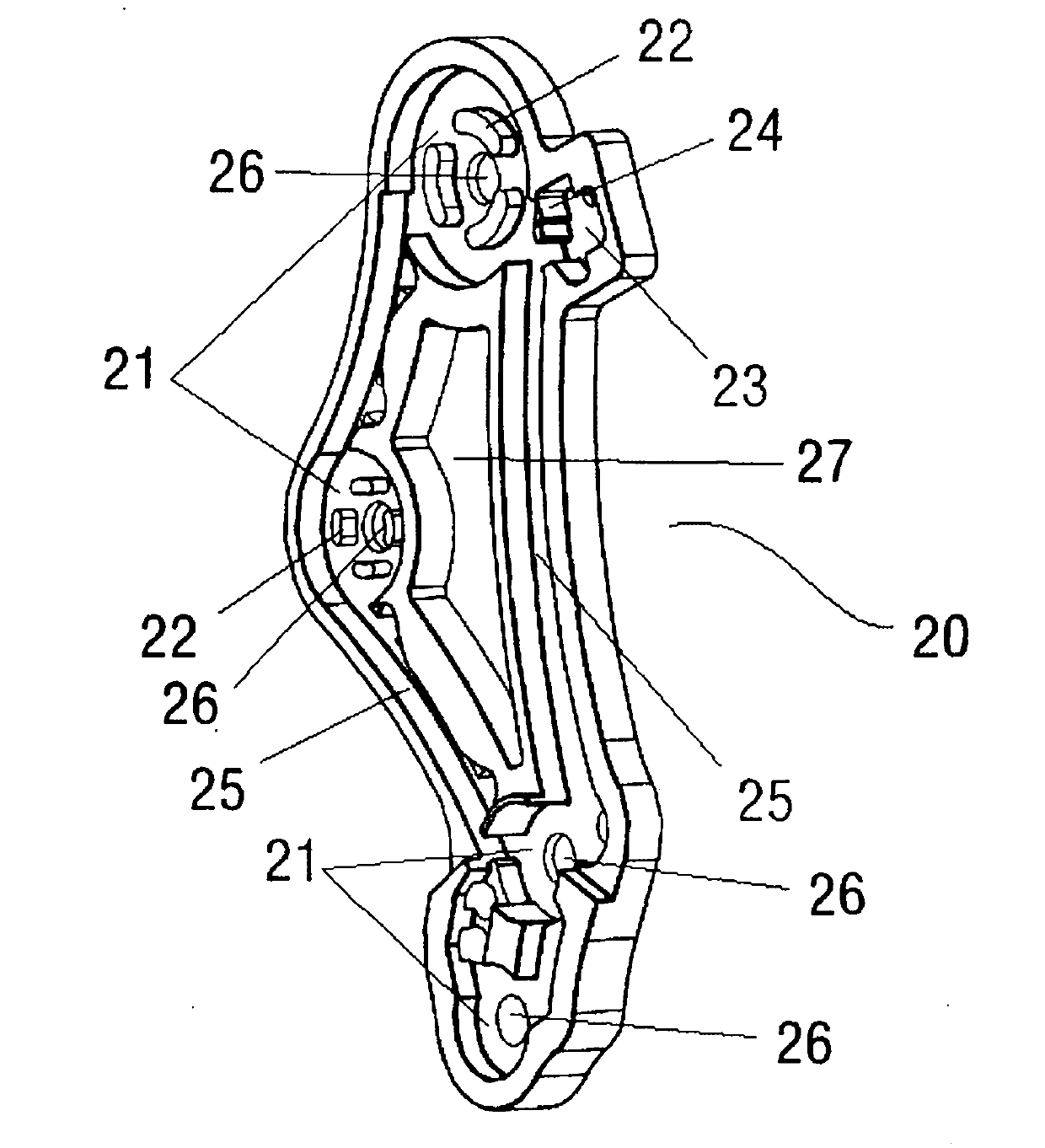

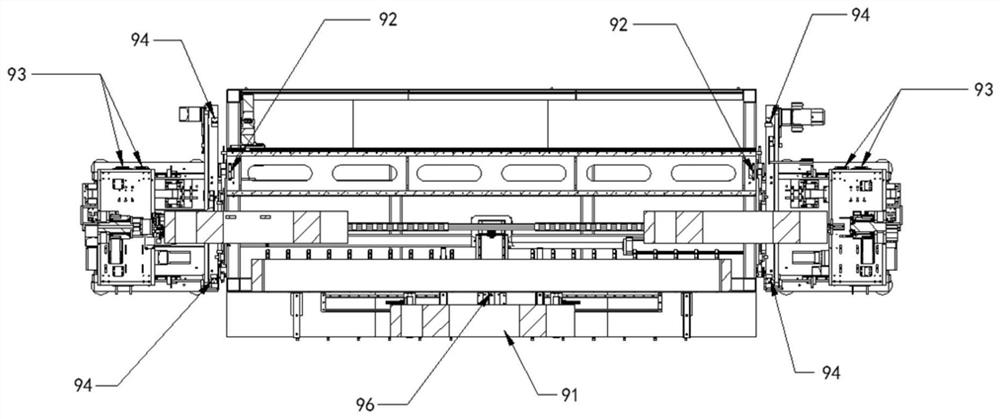

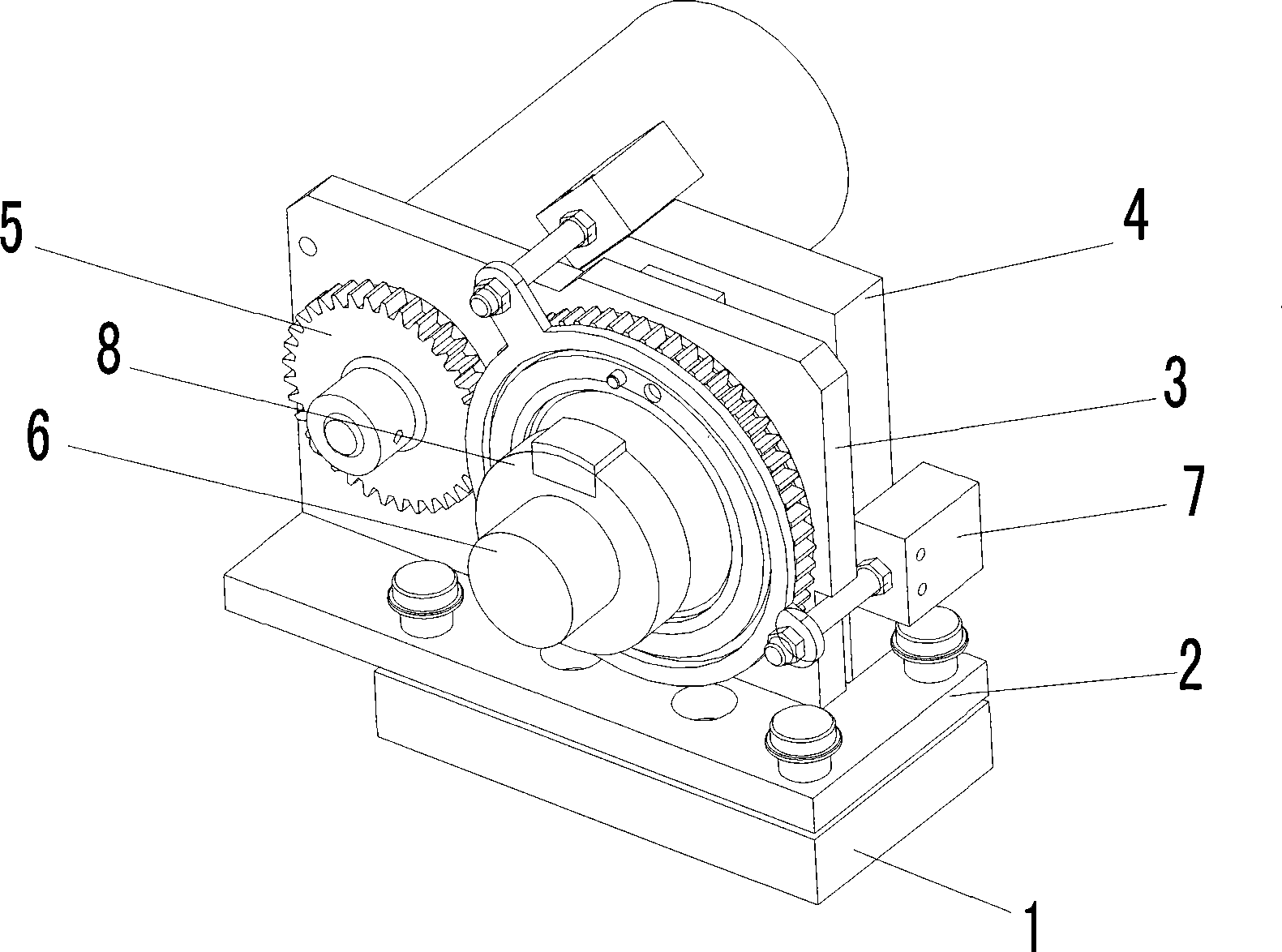

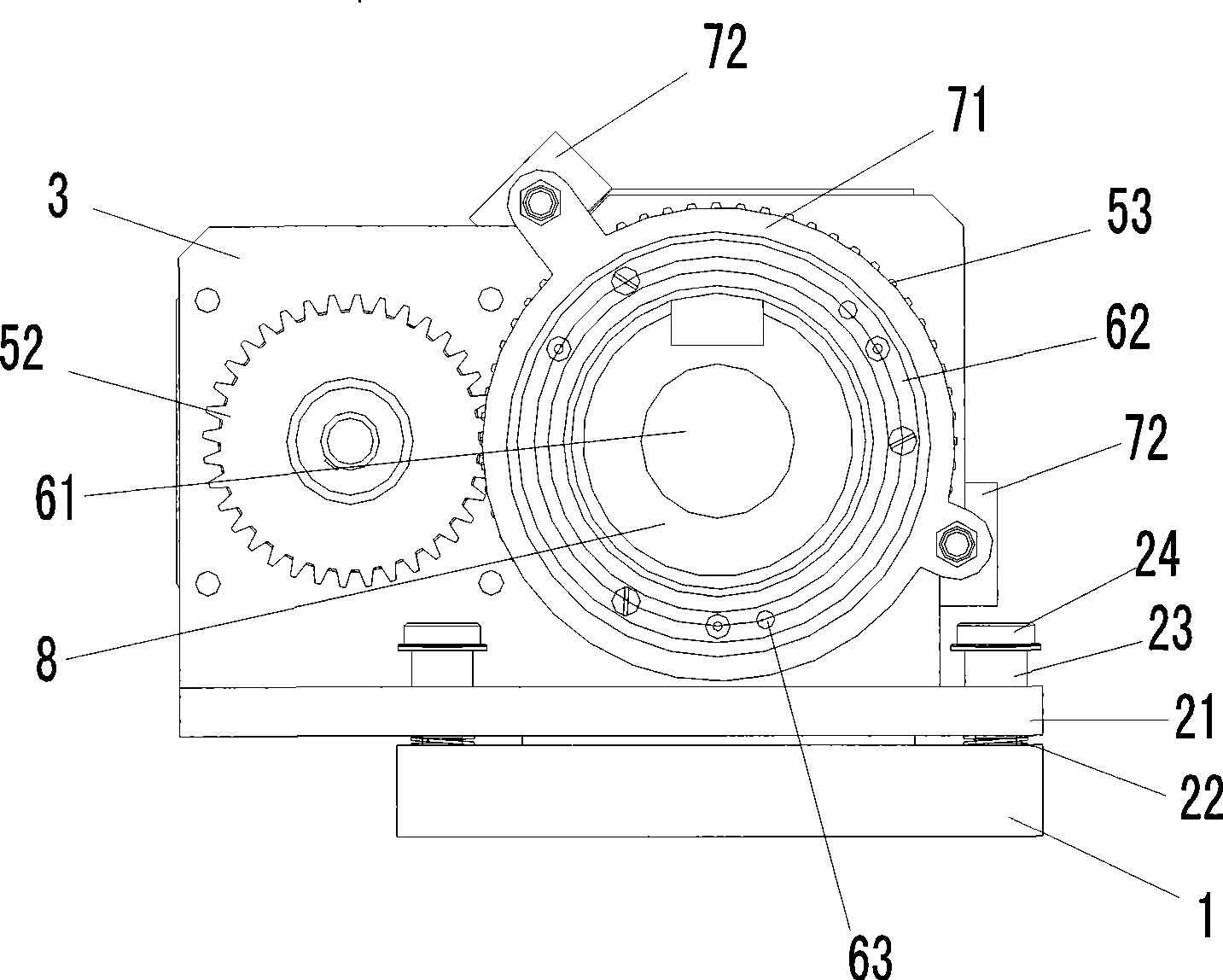

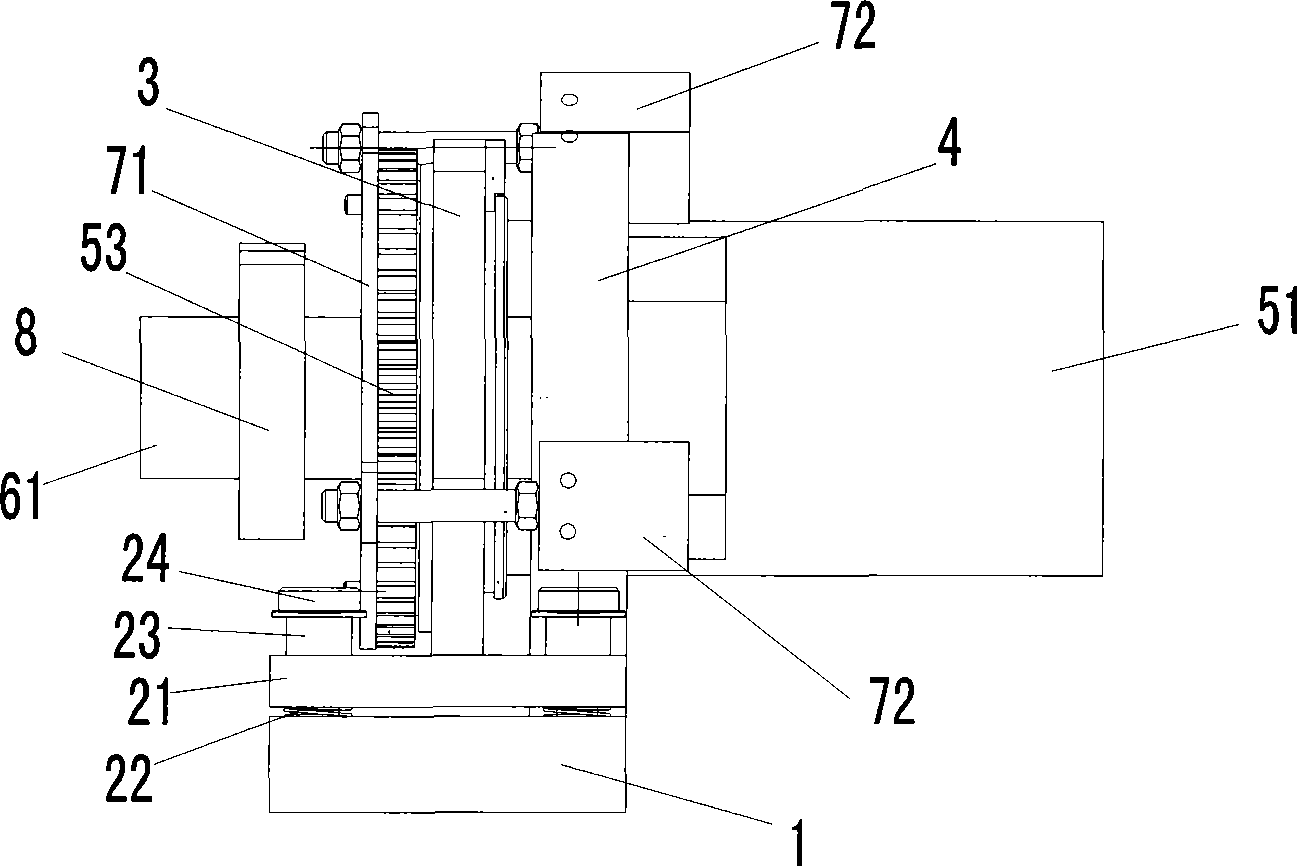

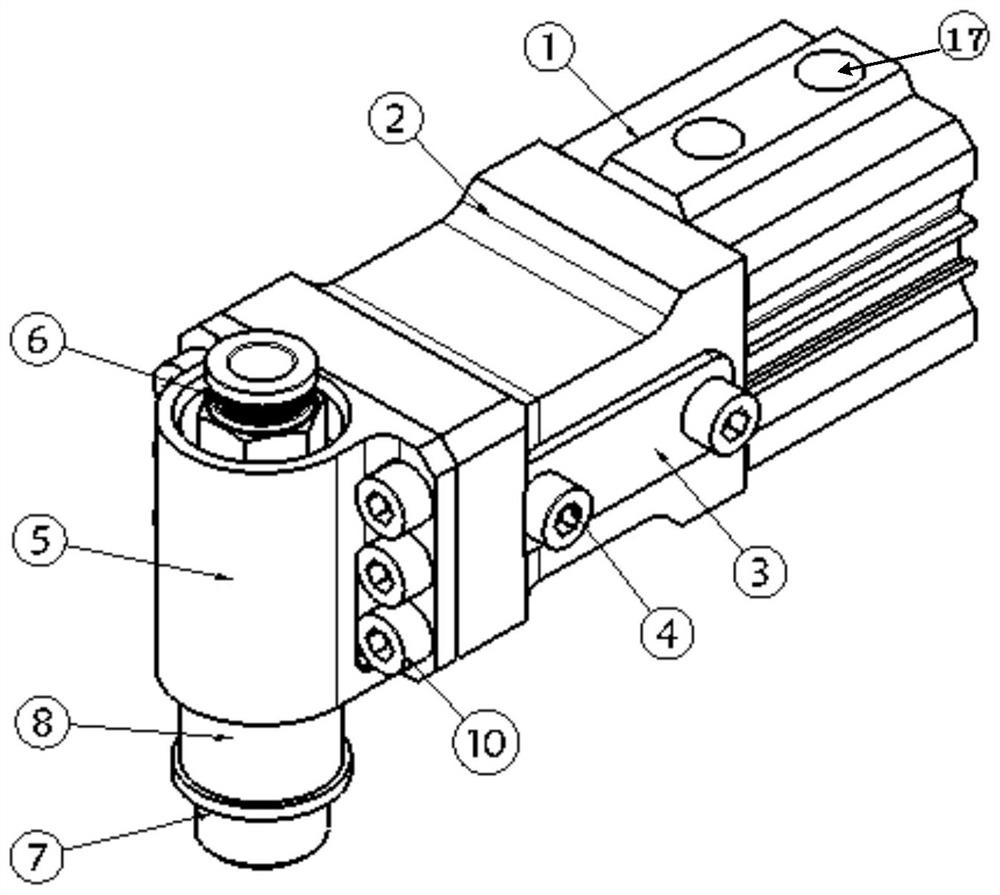

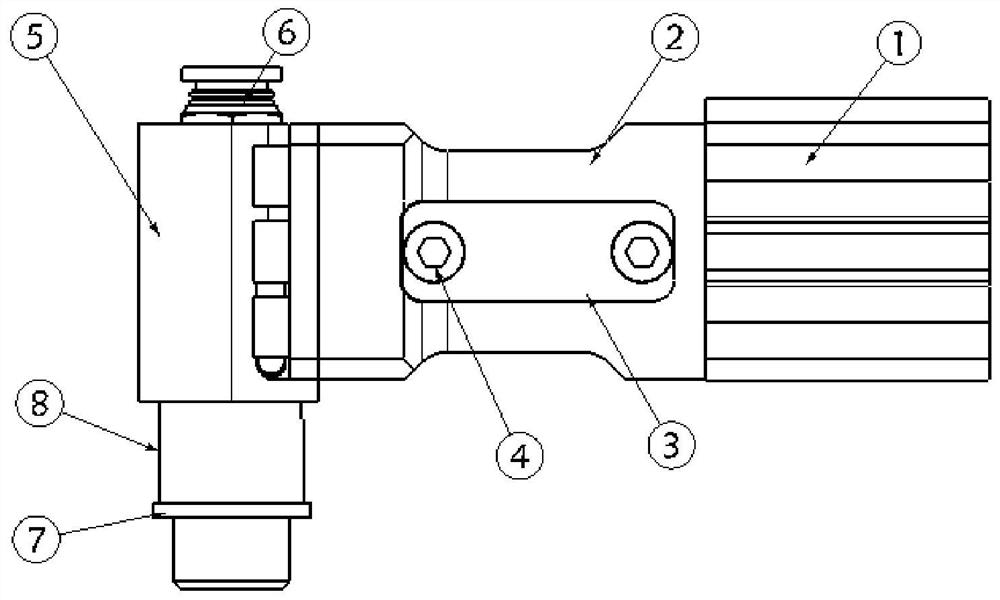

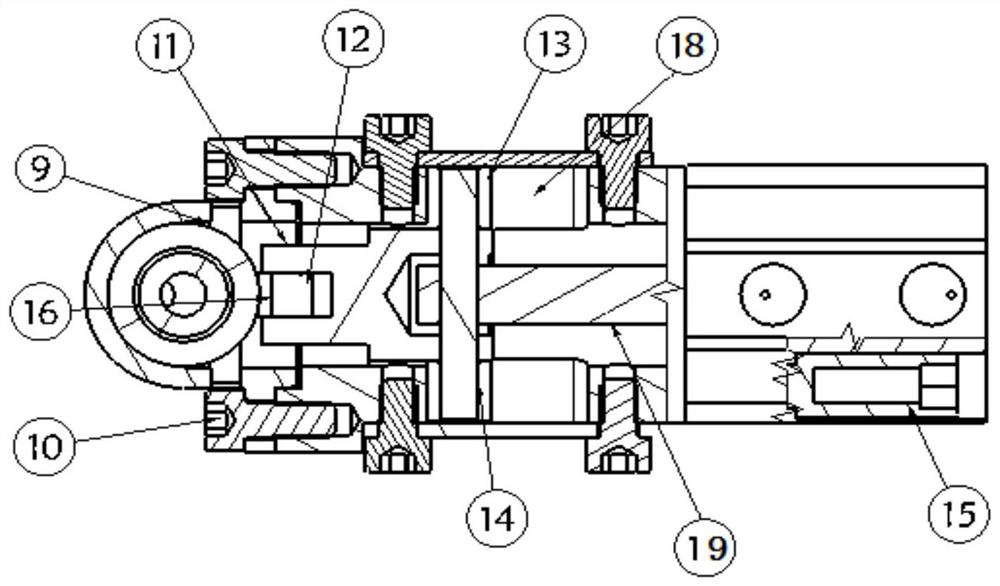

Z-direction compensation mechanism

ActiveCN110773661AReduce avoidance spaceStable and reliable adsorptionMetal-working feeding devicesPositioning devicesProduction lineReciprocating motion

The invention provides a Z-direction compensation mechanism. The Z-direction compensation mechanism is used on a multi-station tooling on an automatic stamping production line and is used for being connected with a suction cup to pick up material sheets. According to the Z-direction compensation mechanism, a connecting rod mechanism is driven by an air cylinder to enable a suction cup connecting sliding column to do reciprocating motion, so that picking and storage of the material sheets are guaranteed; and in the moving process, a plurality of tooling parts do not need to do reciprocating motion at the same time, so that the phenomenon of serious shaking is avoided, and the occupied space and the die avoiding space are reduced.

Owner:沈阳泰德自动化设备有限公司

Microscopic slide automatic feeding device

Owner:南京福怡科技发展股份有限公司

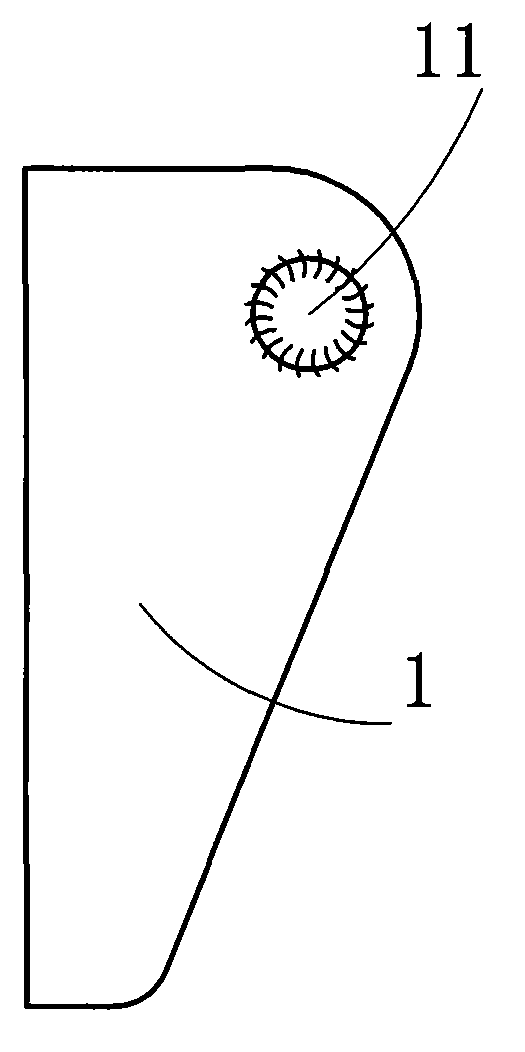

Welding structure for bottom fork shock absorption shaft of motorcycle

The invention discloses a welding structure for a bottom fork shock absorption shaft of a motorcycle. The welding structure comprises a shock absorption supporting plate provided with a welding hole and a shock absorption shaft which is inserted into the welding hole and is integrally welded with the shock absorption supporting plate; a welding part which is larger than the welding hole is arranged on one part, which is close to the end part, of the shock absorption shaft; the distance between the welding part and the end part of the shock absorption shaft is greater than the thickness 3MM of the shock absorption supporting plate; a welding point is arranged between the welding part and the shock absorption supporting plate. The welding structure for the bottom fork shock absorption shaft of the motorcycle is simple in structure; the welding part which is larger than the welding hole is arranged on one part, which is close to the end part, of the shock absorption shaft, and the distance between the welding part and the end part of the shock absorption shaft is greater than the thickness 3MM of the shock absorption supporting plate; the welding point is arranged between the welding part and the end part of the shock absorption supporting plate. The end point, which is far away from the shock absorption shaft, of the welding part is greater than the thickness 3MM of the shock absorption supporting plate so that the welding is convenient; the welding part is not easy to release after being welded, the welding stability is good and the structure is firm and reliable.

Owner:余远平

A z-direction compensation mechanism

ActiveCN110773661BReduce avoidance spaceStable and reliable adsorptionMetal-working feeding devicesPositioning devicesProduction lineReciprocating motion

Owner:沈阳泰德自动化设备有限公司

Formula and production method of special putty-based mixture for aerated block masonry

The invention relates to a formula of a special putty base mixture for aerated block masonry, and a preparation method of the special putty base mixture. The preparation method comprises the following steps: preparing a special barrel with the volume of 50L; sequentially adding 62.2-73.8wt% of putty powder, 4.8-6.5wt% of cement, 6.6-8.0wt% of gypsum powder, 1.5-2.3wt% of cast stone powder, 4.2-5.5wt% of talcum powder, 2.3-3.0wt% of diatomite, 3.4-4.0wt% of water, 0.9-1.5wt% of a flexible adhesive and 4.2-5.3wt% of a crack resistance additive to the special barrel; and stirring by using a portable electric stirring machine for 3-5min to form a uniform paste, allowing the paste to stand for 5-10min, and stirring to obtain the putty base mixture which can be instantly used. The special putty base mixture can be directly smeared on the aerated block masonry to omit a mortar plastering process and avoid material sprinkling, so the environment is healthy, and cracking and bubbling are avoided; and the special putty base mixture has the advantages of high strength, large adhesion, and no shedding in wet environment.

Owner:NANTONG SIJIAN CONSTR GRP

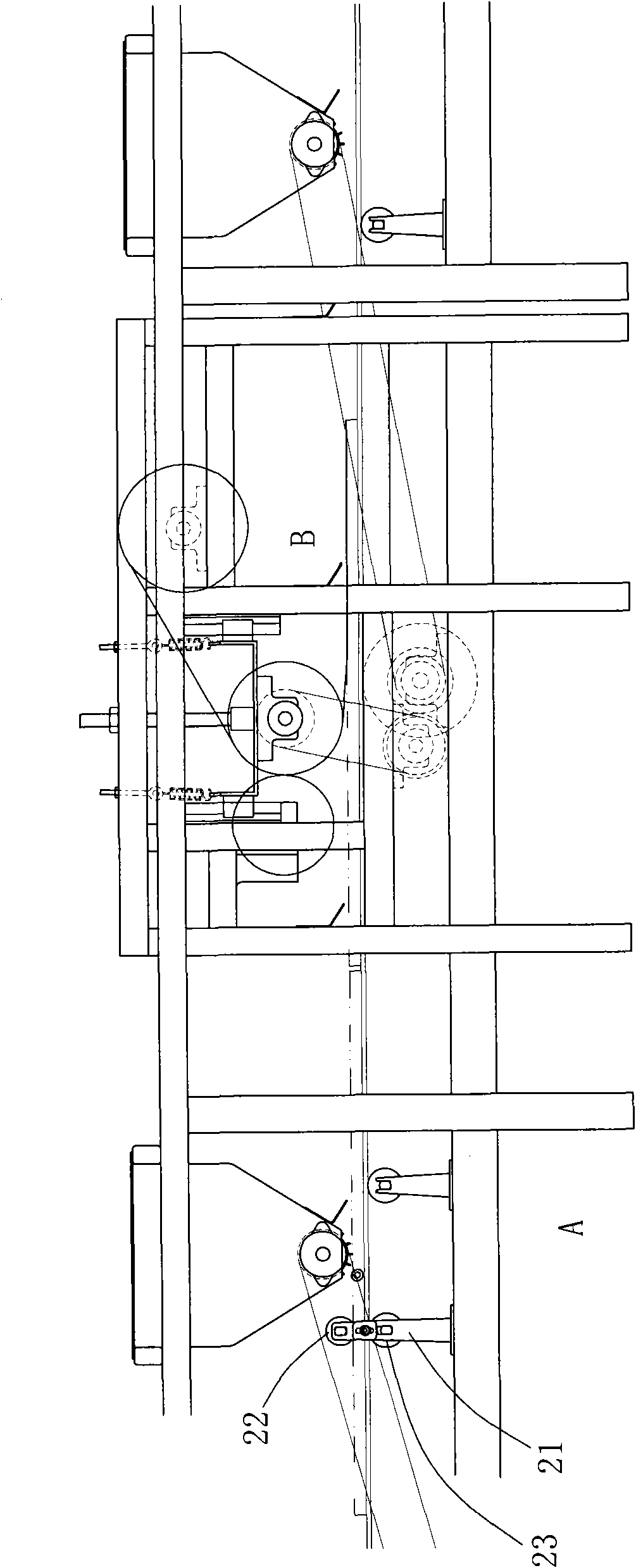

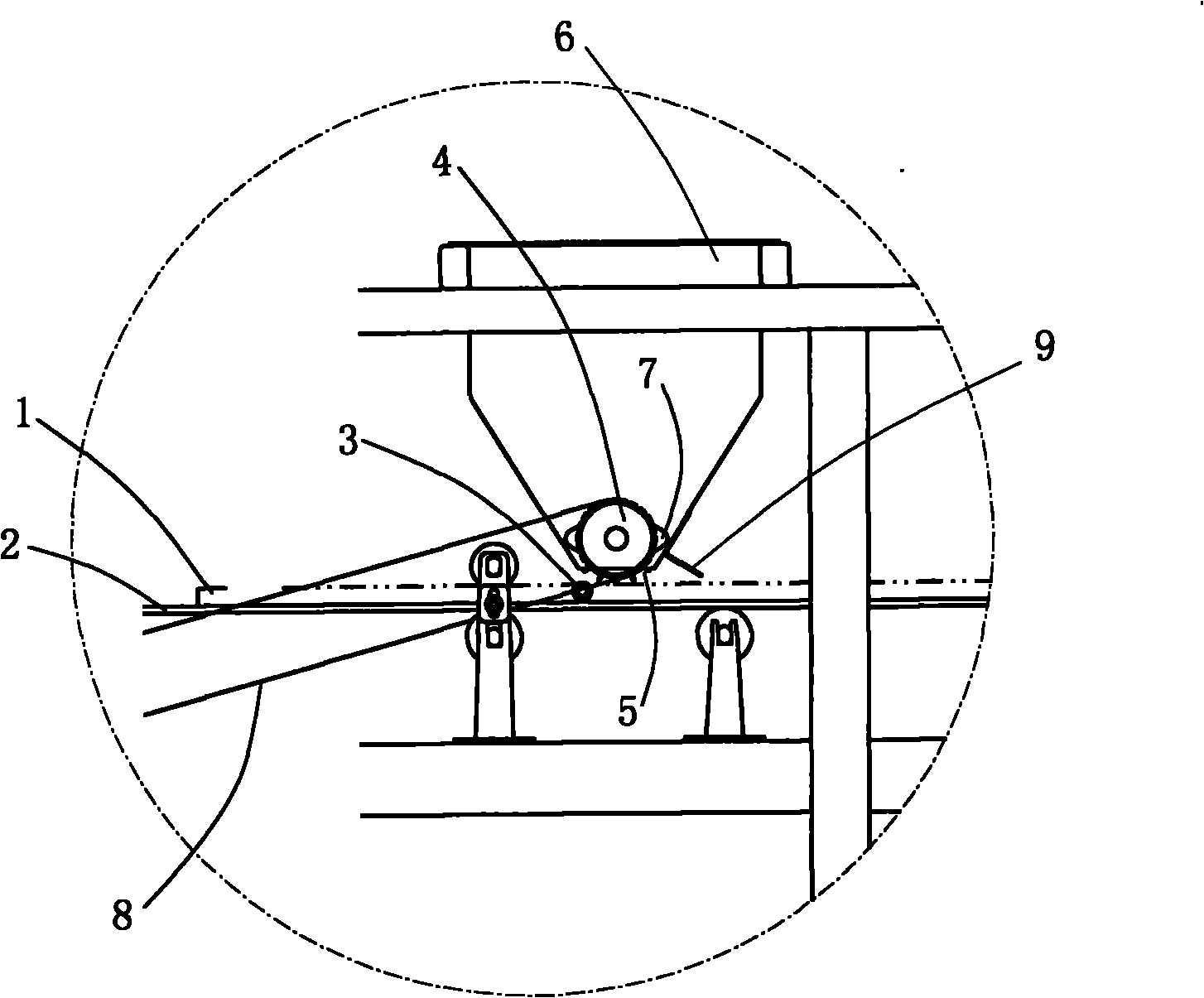

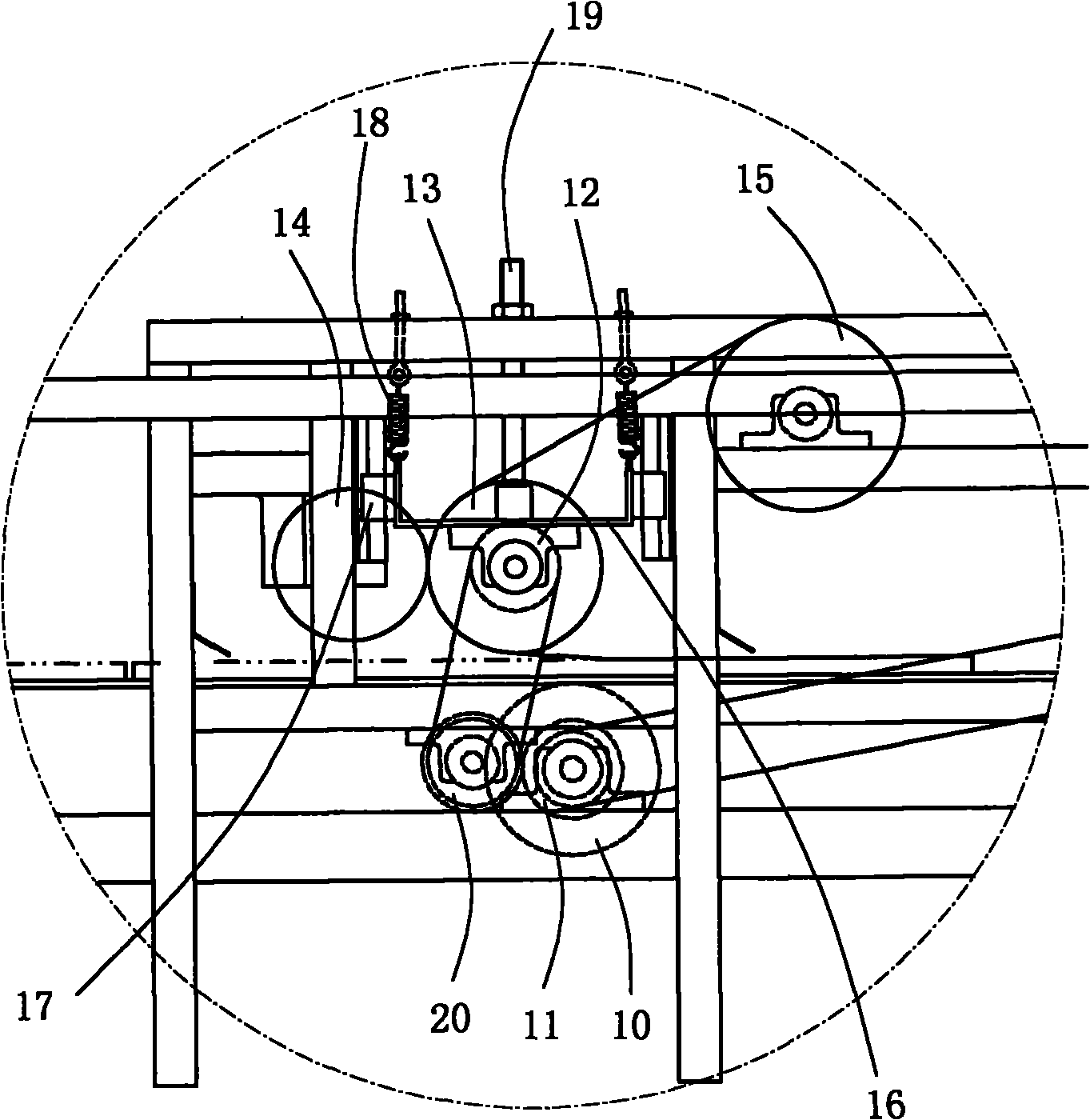

Grouting and lapping machine for outer wall insulation boards

InactiveCN101837610AImprove uniformityHigh strengthCeramic shaping apparatusCement slurryEngineering

The invention discloses a grouting and lapping machine for outer wall insulation boards. Along the advancing direction of a workpiece conveyer belt, a grouting station, a lapping station and a secondary grouting position are sequentially arranged on a chassis, the grouting station smears cement slurry on workpieces, the lapping station spreads a reinforcing mesh fabric on the cement slurry surface, and another layer of cement slurry is then smeared on the mesh fabric. Since the machine sequentially carries out the processes of primary grouting, lapping and secondary grouting together, the cement bodies can be organically integrated with the mesh fabric, the uniformity of the covering layer is improved, the strength of the cement surface of polystyrene insulation material is enhanced, and cement product-filled interlayers do not need to be separately constructed by the conventional technique. Secondly, since the three processes are carried out in one step, the working efficiency and the product quality are increased, the labor intensity is reduced, and the production cost is decreased.

Owner:合肥乐千年涂料有限公司

Construction method of special putty-based mixture for smearing aerated block masonry

The invention discloses a construction method of a special putty-based mixture for coating an aerated block masonry. The construction method comprises the following steps: (1) a concave-convex part of a wall is physically treated, and is moisturized by water; (2) the special putty-based mixture is prepared; putty powder of 62.2-73.8%, cement of 4.8-6.5%, gypsum powder of 6.6-8.0%, cast stone powder of 1.5-2.3%, talcum powder of 4.2-5.5%, kieselguhr of 2.3-3.0%, water of 3.4-4.0%, flexible adhesive glue of 0.9-1.5% and crack resistant additive of 4.2-5.3% are added in a special barrel of 50 L in percentage by weight in sequence, are stirred for 3-5 minutes, and are subjected to still standing for 5-10 minutes; (3) a masonry mortar joint is filled by the special putty-based mixture; (4) a joint of the concrete and a masonry wall surface is filled by the special putty-based mixture, and is bonded with alkali-resisting glass fiber gridding cloth; (5) the special putty-based mixture of 4-6 mm is pressed into the alkali-resisting glass fiber gridding cloth; (6) the special putty-based mixture is used for leveling; and (7) general putty is coated once; and emulsion paint is brushed for two times. The special putty-based mixture is high in strength and great in adhesive force, and is directly combined with the aerated block masonry without being deformed and dropped.

Owner:NANTONG SIJIAN CONSTR GRP

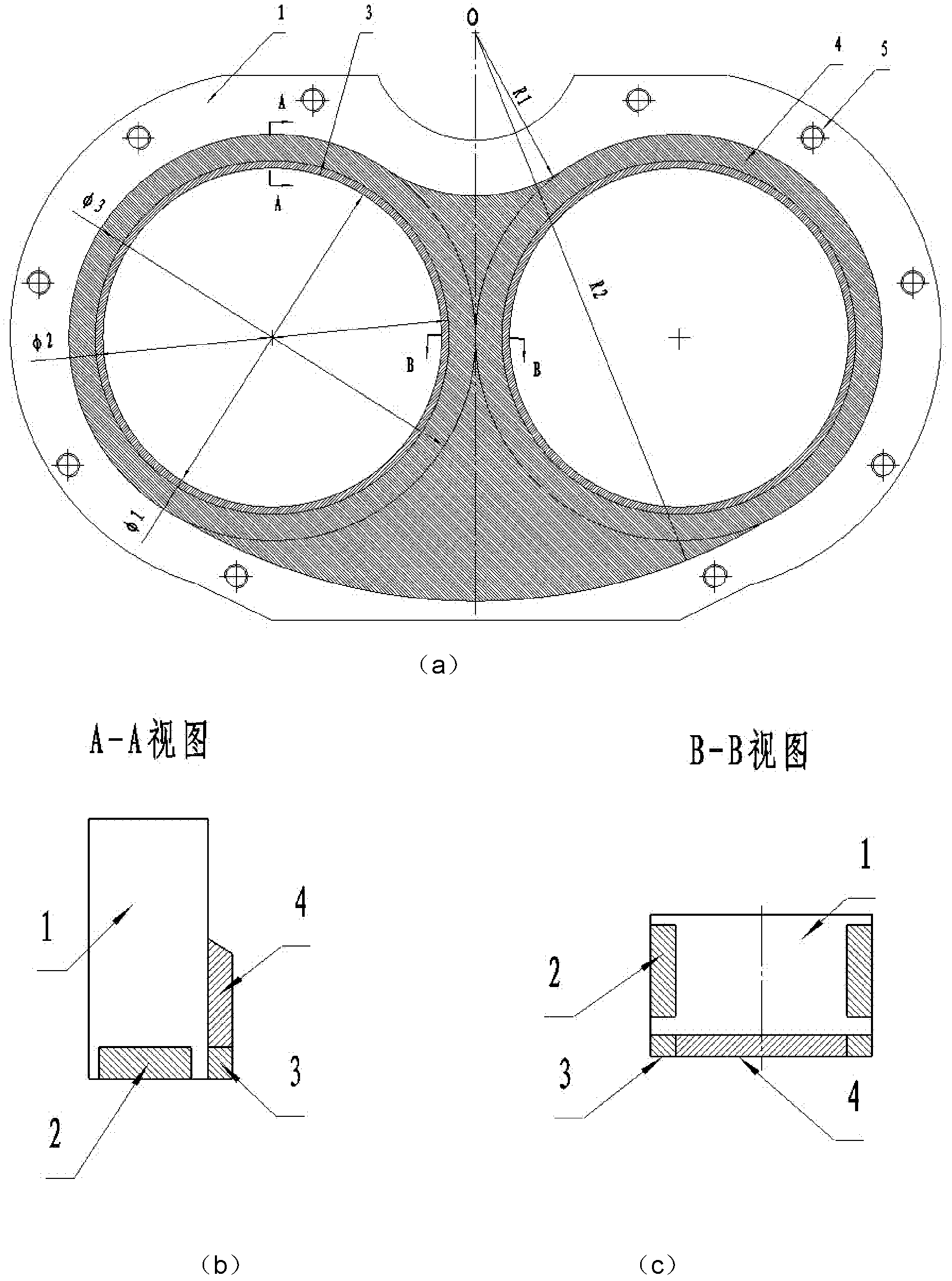

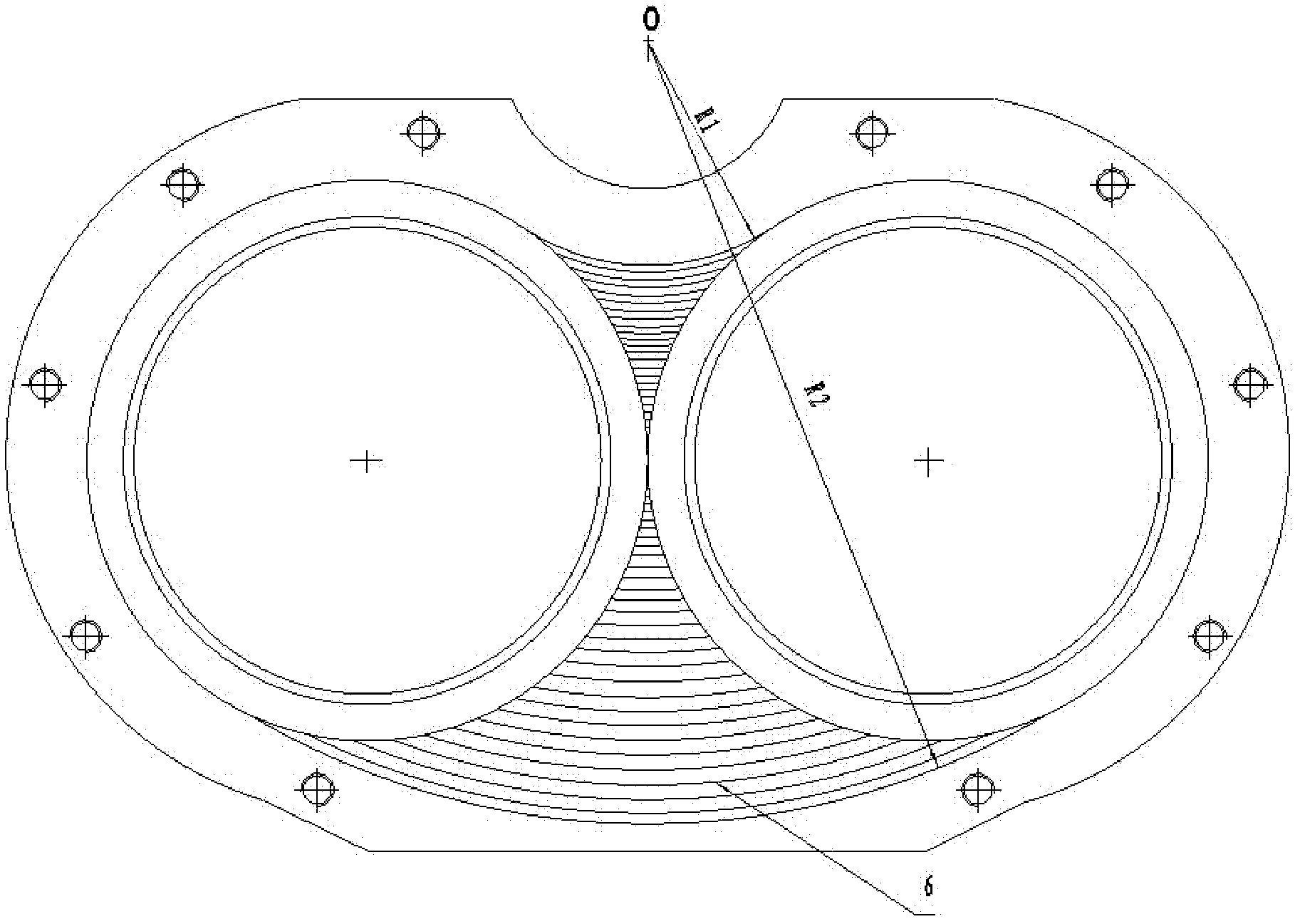

Dual-alloy cladding layer wear plate and preparation method

InactiveCN102517578BSelf-fluxingNot fall offPositive displacement pump componentsMetallic material coating processesChemical compositionProcessing cost

A dual-alloy cladding layer wear plate and a preparation method relate to the field of wear plate of a concrete pumper. Bores of a wear plate matrix and inner rings of glasses are cladded with ferrous alloy by laser; and outer rings of the glasses are cladded with nickel tungsten alloy by laser. The ferrous alloy comprises chemical components of 0.40-0.70 wt% of C, 2.0-3.0 wt% of B, 20-24 wt% of Cr, 4-7 wt% of Ni, 1.8-3.0 wt% of Si and the balance of Fe. The nickel tungsten alloy comprises chemical components of 2.2-2.7 wt% of C, 10-13 wt% of Cr, 1.8-2.8 wt% of Si, 50-60 wt% of W, 1.5-2.4 wt%of B and the balance of Ni. In order to prolong a service life of the wear plate and according to failure characteristics of different working positions, different alloy materials are cladded by laser to reach the goal of saving precious metal materials and reducing processing cost.

Owner:BEIJING UNIV OF TECH

Grouting and lapping machine for outer wall insulation boards

InactiveCN101837610BImprove uniformityHigh strengthCeramic shaping apparatusPolystyreneCement slurry

The invention discloses a grouting and lapping machine for outer wall insulation boards. Along the advancing direction of a workpiece conveyer belt, a grouting station, a lapping station and a secondary grouting position are sequentially arranged on a chassis, the grouting station smears cement slurry on workpieces, the lapping station spreads a reinforcing mesh fabric on the cement slurry surface, and another layer of cement slurry is then smeared on the mesh fabric. Since the machine sequentially carries out the processes of primary grouting, lapping and secondary grouting together, the cement bodies can be organically integrated with the mesh fabric, the uniformity of the covering layer is improved, the strength of the cement surface of polystyrene insulation material is enhanced, and cement product-filled interlayers do not need to be separately constructed by the conventional technique. Secondly, since the three processes are carried out in one step, the working efficiency and the product quality are increased, the labor intensity is reduced, and the production cost is decreased.

Owner:合肥乐千年涂料有限公司

Connector and light source device

InactiveCN101740984BImprove reliabilityNot fall offCoupling device connectionsElectric discharge tubesElectrical and Electronics engineeringLight source

The invention relates to a connector comprising an insulating seat, two electrode posts and two L-shaped electrode slices, wherein the insulating seat is provided with a first side surface, a second side surface opposite to the first side surface, a lower surface for connecting the first side surface with the second side surface and two through holes, and the two through holes penetrate through the insulating seat and extend to the second side surface from the first side surface; the two electrode posts respectively penetrate through the two through holes, each electrode post is provided witha first end and a second end which are opposite to each other, and the first end protrudes the first side surface; each L-shaped electrode slice comprises a bottom arranged on the lower surface and aconnecting part connected to the bottom, and the connecting parts are arranged on the second side surface and are respectively connected to the second ends of the electrode posts.

Owner:EVERLIGHT ELECTRONICS

Oil inlet/outlet connector of front telescopic sleeve hydraulic oil cylinder of dumper

InactiveCN105298983ASmooth installationGuaranteed usuallyFluid-pressure actuatorsEngineeringMechanical engineering

The invention provides an oil inlet / outlet connector of a front telescopic sleeve hydraulic oil cylinder of a dumper. The oil inlet / outlet connector of the front telescopic sleeve hydraulic oil cylinder of the dumper comprises the hydraulic oil cylinder. A connector base is correspondingly installed on a first oil inlet in the side face of the hydraulic oil cylinder. A hollow pipe is arranged in the connector base and corresponds to the first oil inlet. A plurality of second oil inlets communicated with the hollow pipe are formed in the connector base in the radial direction. A rotary connector corresponding to the multiple second oil inlets is arranged on the connector base. The inner side of the rotary connector forms an annular channel outside the multiple second oil inlets, and the annular channel is communicated with an oil inlet of the rotary connector. Sealing rings are arranged on the two sides of the annular channel of the rotary connector, and the rotary connector and the connector base form a relative sealing environment through the sealing rings. A check ring is arranged on the connector base and located outside the rotary connector. According to the oil inlet / outlet connector of the front telescopic sleeve hydraulic oil cylinder of the dumper, 360-degree rotation and connection of the connector of the hydraulic oil cylinder can be achieved without direction limitation; the structure is simple, the problem of interference of the installation process is solved, and thus installation is smoother.

Owner:HUBEI MAIKEYAQI NEW ENERGY TECH

Full-automatic double-ccd photosensitive element digital microscope

ActiveCN102122066BTo achieve the purpose of intelligent screeningGuaranteed effectMicroscopesDigital imageOptical density

The invention discloses a full-automatic double-ccd (charge-coupled device) photosensitive element digital microscope, which is used for acquiring specimen image information by synchronously using a colored ccd photosensitive element and a black-and-white ccd photosensitive element so as to obtain a multifocal plane holographic three-dimensional image, synchronously outputting a specimen reading result according to nucleus integral optical density acquired by the black-and-white ccd photosensitive element, and finally outputting a specimen picture and text report. Additionally, the full-automatic double-ccd photosensitive element digital microscope comprises a slide uploading and unloading device and a horizontal migration clamping device for automatically changing the specimen slide, andthen, the slide is located in three dimensions through a three-dimensional frame, so that the colored ccd photosensitive element and the black-and-white ccd photosensitive element can conveniently acquire the image information of the specimen. Thus, the full-automatic double-ccd photosensitive element digital microscope can be used for not only performing morphological observation on the specimen, but also taking digital images for a dyed tissue section so as to form the multi-focal plane holographic three-dimensional image, so that all the information of the cell can be observed in multiple layers and multiple focal planes, and accuracy of early diagnosis is greatly improved.

Owner:湖南港湾科学仪器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com