Formula and production method of special putty-based mixture for aerated block masonry

A technology of aerated blocks and mixtures, applied in the field of building walls, can solve the problems of low adhesion, pollution of the environment, easy cracking and falling off, etc., and achieve the effects of avoiding spillage, high adhesion, and avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

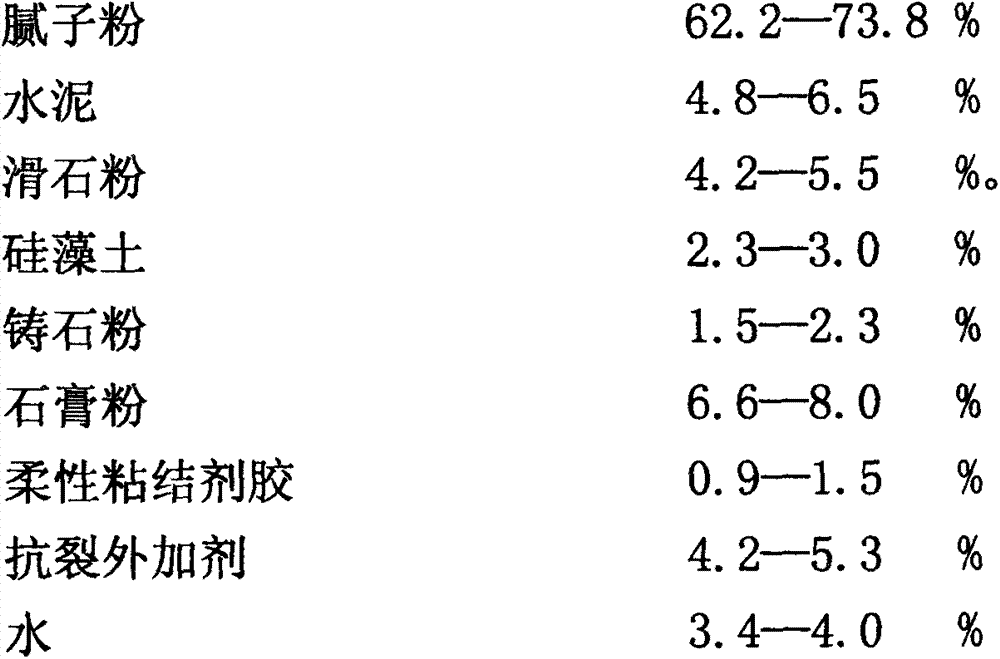

[0008] Example 1, the special putty-based mixture for aerated block masonry consists of putty powder, cement, talcum powder, diatomaceous earth, cast stone powder, gypsum powder, flexible adhesive glue, anti-cracking additive, and water. By weight percentage, the percentage by weight of each component is: putty powder 68.3%, cement 5.6%, talcum powder 4.7%, diatomite 2.6%, cast stone powder 1.8%, gypsum powder 7.2%, and the flexible adhesive glue is selected WX -204 type flexible adhesive glue 1.2%, anti-crack additive 4.8%, water 3.8%. The production method of special putty-based mixture for aerated block masonry: prepare a special bucket with a volume of 50 liters. Add putty powder, cement, gypsum powder, cast stone powder, talcum powder, diatomaceous earth, water, WX-204 type flexible adhesive glue, and anti-cracking admixture in the special bucket in sequence, by weight percentage, putty powder 68.3%, Cement 5.6%, gypsum powder 7.2%, cast stone powder 1.8%, talc powder 4....

Embodiment 2

[0009] Example 2, the special putty-based mixture for aerated block masonry consists of putty powder, cement, talc powder, diatomaceous earth, cast stone powder, gypsum powder, flexible adhesive glue, anti-cracking additive, and water. By weight percentage, the percentage by weight of each component is: putty powder 68.1%, cement 6.3%, talcum powder 4.8%, diatomite 2.4%, cast stone powder 2.1%, gypsum powder 6.9%, and the flexible adhesive glue is selected WX -204 type flexible adhesive glue 1.4%, anti-crack additive 4.4%, water 3.6%. The production method of special putty-based mixture for aerated block masonry: prepare a special bucket with a volume of 50 liters. Add putty powder, cement, gypsum powder, cast stone powder, talcum powder, diatomaceous earth, water, WX-204 type flexible adhesive glue, and anti-cracking admixture in the special barrel in sequence, by weight percentage, putty powder 68.1%, 6.3% of cement, 6.9% of gypsum powder, 2.1% of cast stone powder, 4.8% of...

Embodiment 3

[0010] Example 3, the special putty-based mixture for aerated block masonry consists of putty powder, cement, talcum powder, diatomaceous earth, cast stone powder, gypsum powder, flexible adhesive glue, anti-cracking additive, and water. By weight percentage, the percentage by weight of each component is: putty powder 67.2%, cement 6.1%, talcum powder 5.1%, diatomaceous earth 2.9%, cast stone powder 1.6%, gypsum powder 7.8%, flexible adhesive glue is selected WX - 1.1% of 204 type flexible adhesive glue, 4.5% of anti-cracking admixture, and 3.7% of water. The production method of special putty-based mixture for aerated block masonry: prepare a special bucket with a volume of 50 liters. Add putty powder, cement, gypsum powder, cast stone powder, talcum powder, diatomaceous earth, water, WX-204 type flexible adhesive glue, and anti-cracking admixture in the special barrel in sequence, by weight percentage, putty powder 67.2%, 6.1% of cement, 7.8% of gypsum powder, 1.6% of cast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com